Method for preparing novel red magnesium barium germinate fluorescent powder for displaying

A magnesium germanate and phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of lack of extensive and in-depth research on new luminophores, and achieve the effect of simple and easy method and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

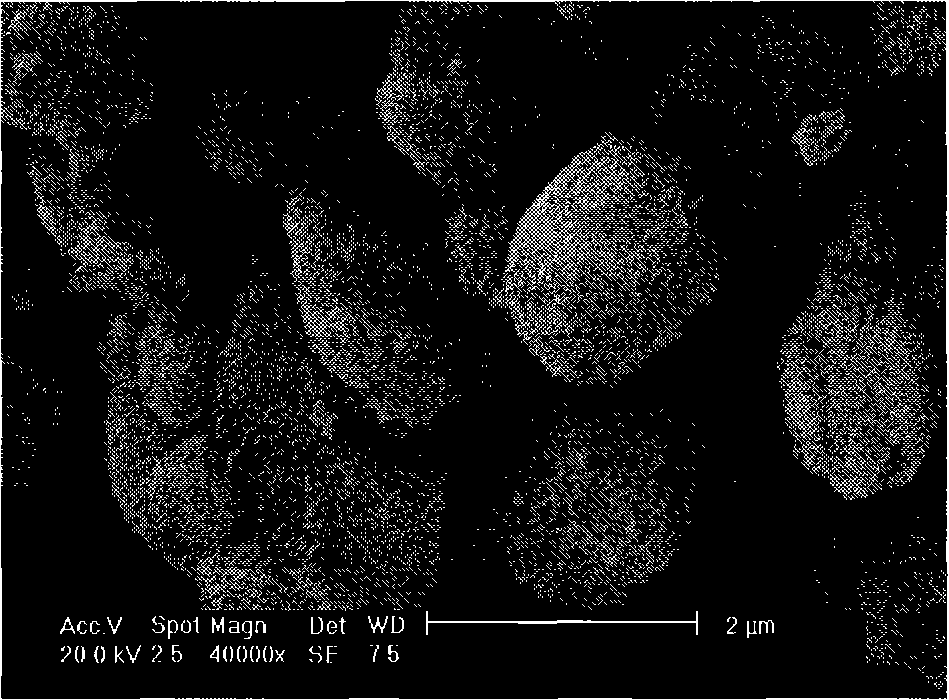

[0036] According to the stoichiometric ratio Ba 1.92 MgGe 2 o 7 :Eu 3+ 0.08 Weigh 0.379 g of BaCO 3 , 0.097 g (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O, 0.209 g GeO 2 , 0.014 g Eu 2 o 3 and 0.6136 grams of NaCl and 0.7828 grams of KCl, put them into an agate mortar and grind until the reaction materials are mixed evenly and reach a certain fineness (usually about 30 minutes), then transfer to a corundum crucible and bake at 850 ° C for 6 hours and then cool in the furnace Take it out at room temperature, soak it in deionized water at about 60°C, and wash it several times. 3 Solution test without Cl - Dry in an oven at 80°C for 24h to obtain ~2μm Ba 1.92 MgGe 2 o 7 :Eu 3+ 0.08 Powder.

Embodiment 2

[0038] According to the stoichiometric ratio Ba 1.92 MgGe 2 o 7 :Eu 3+ 0.08 Weigh 0.294 gram BaO, 0.097 gram (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O, 0.209 g GeO 2 , 0.019 g Eu 2 (CO 3 ) 3 and 0.580 g of NaCl (0.010 mol), put it into an agate mortar and grind until the reaction raw materials are mixed evenly and reach a certain fineness (usually about 30 minutes), then transfer to a corundum crucible and bake at 750 ° C for 3 hours, then cool with the furnace Take it out at room temperature, soak it in deionized water at about 70°C, and wash it several times until the AgNO 3 Solution test without Cl - Dry in an oven at 80°C for 24h to obtain ~2μmBa 1.92 MgGe 2 o 7 :Eu 3+ 0.08 Powder.

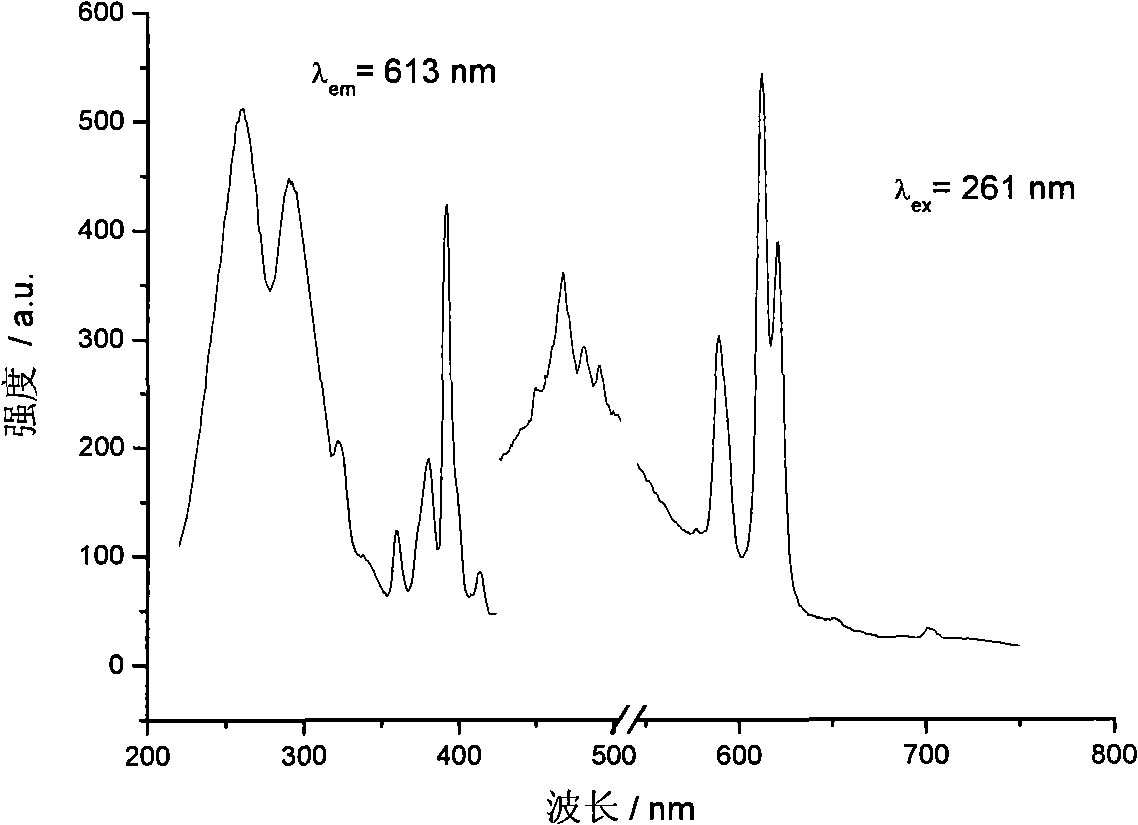

[0039] From figure 1 It can be seen from the figure that the excitation and emission spectra of the obtained phosphor are obtained under the monitoring wavelength of 613nm. From the excitation diagram, it can be seen that the excitation peak is composed of two parts, and the 261 and 291...

Embodiment 3

[0041] According to the stoichiometric ratio Ba 1.92 MgGe 2 o 7 :Eu 3+ 0.08 Weigh 0.379 g of BaCO 3 , 0.097 g (MgCO 3 ) 4 ·Mg(OH) 2 ·5H 2 O, 0.209 g GeO 2 , 0.014 g Eu 2 o 3 Put 2.097 grams of NaCl three times the mass of the reaction raw materials into an agate mortar and grind until the reaction raw materials are mixed evenly and reach a certain fineness (usually about 30 minutes), and then transferred to a corundum crucible and roasted at 900 ° C for 8 hours Take it out with the furnace cooling to room temperature, soak it in deionized water at about 100°C, and wash it several times. 3 Solution test without Cl - Dry in an oven at 85°C for 24h to obtain ~2μm Ba 1.92 MgGe 2 o 7 :Eu 3+ 0.04 Powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com