Process for purifying benzo pollutants in waste water

A technology for benzene-based pollutants and waste water, applied in water pollutants, chemical instruments and methods, extraction water/sewage treatment, etc., can solve the problems of rectification method, high price of diethylbenzene, difficulty in recovering extractant, etc. , to achieve better separation and extraction effect, easy and safe operation, and reduce purification pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

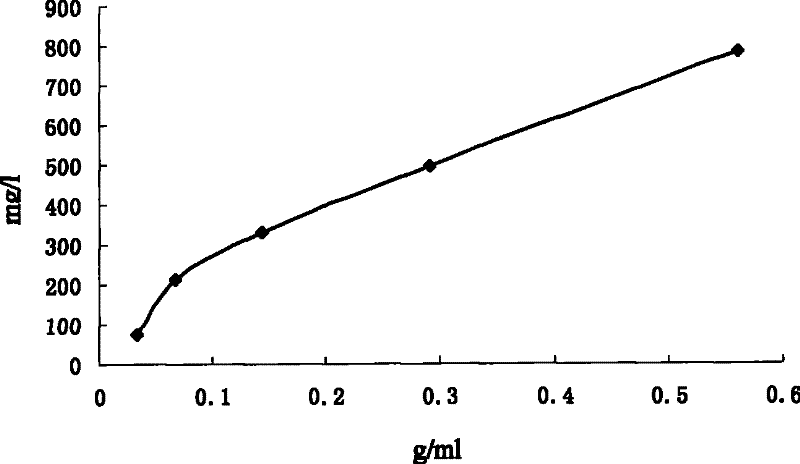

[0038] At room temperature, add n-pentane to the benzene-containing wastewater. The volume ratios of n-pentane and benzene-containing wastewater are 0.2, 0.5, 1, 2 respectively; after vigorous stirring and mixing for 5 minutes, 15 minutes, 60 minutes, and 180 minutes, stop Stir, stand for layering, take 5-10ml of the lower water sample, use acetone as internal standard, add 1-2 drops of acetone to weigh, use Varian3700 gas chromatograph for benzene content detection, chromatographic conditions: sample chamber temperature 80℃ ; Chromatographic column model OV-101, column temperature 40℃; ion head detector 120℃; carrier gas nitrogen, 30ml / min; hydrogen 30ml / min. The results are shown in Table 1. When n-pentane is used as the extractant, the comparison of benzene content in water and oil phases is shown in figure 1 .

Embodiment 2

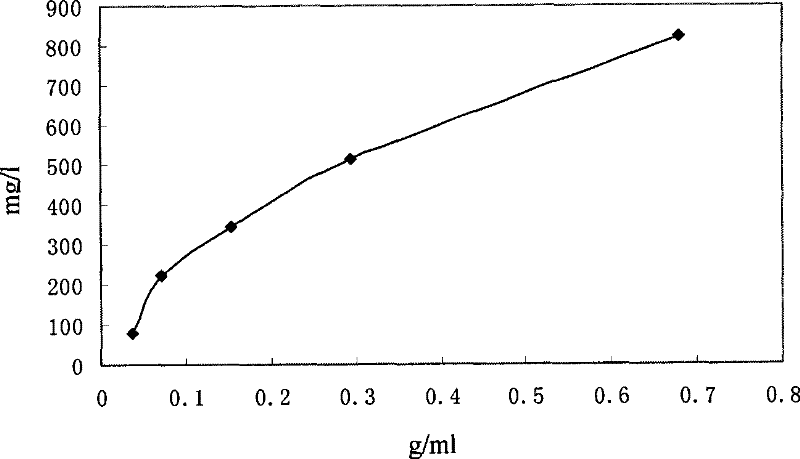

[0040] The operation method and conditions are the same as in Example 1, replacing n-pentane with n-hexane. The test results are shown in Table 1.

Embodiment 3

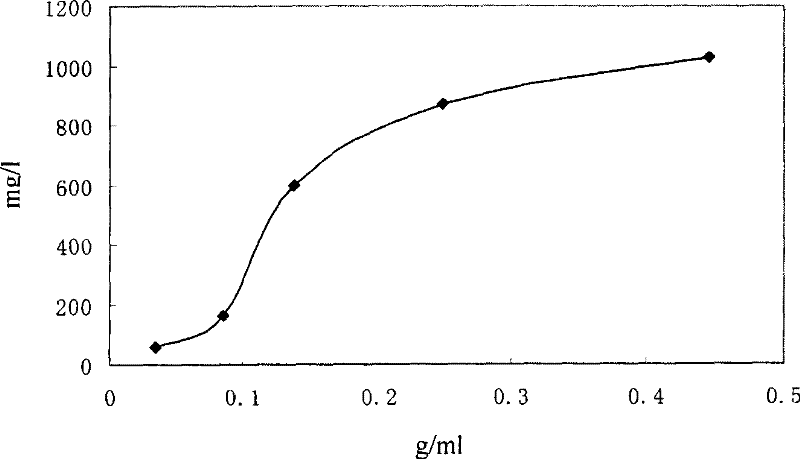

[0042] The operation method and conditions are the same as in Example 1, replacing n-pentane with cyclohexane. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com