High temperature organic exhaust gas integration biological treatment device and process

A technology for organic waste gas and treatment equipment, which is applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as thermal inactivation of microbial degradation bacteria, high cost of removing organic waste gas, and system failure, and achieve start-up Fast, low maintenance cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

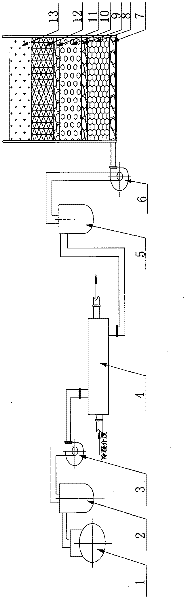

[0023] The integrated biological treatment device of the present invention mainly includes a condensation device and a biological deodorization device. The condensing device includes steam-water separators 2,5, blowers 3,6, and condenser 4. The high-temperature organic waste gas passing through the dryer 1 is collected through the pipeline through the strong ventilation of the fan, and transported to the condenser for condensation and cooling, so that the water vapor is condensed and separated from the gas through the steam-water separation equipment, and the gas temperature drops to the working condition of the biological deodorization device. , transported to the biological deodorization device through the fan. The device consists of a gas distribution layer 7, a grease selection layer 8, a gas distribution layer 9, an inert filler layer 10, a gas distribution layer 11, a biological filler layer 12, and a vegetation layer 13 from bottom to top. The humidity, pH, and tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com