Thiophene compound having sulfonyl group and process for producing the same

A technology of sulfonyl thiophene and bis-sulfonyl thiophene, which is applied in the field of thiophene compounds and its preparation, can solve the problems of difficult control of coating film thickness and low solid concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

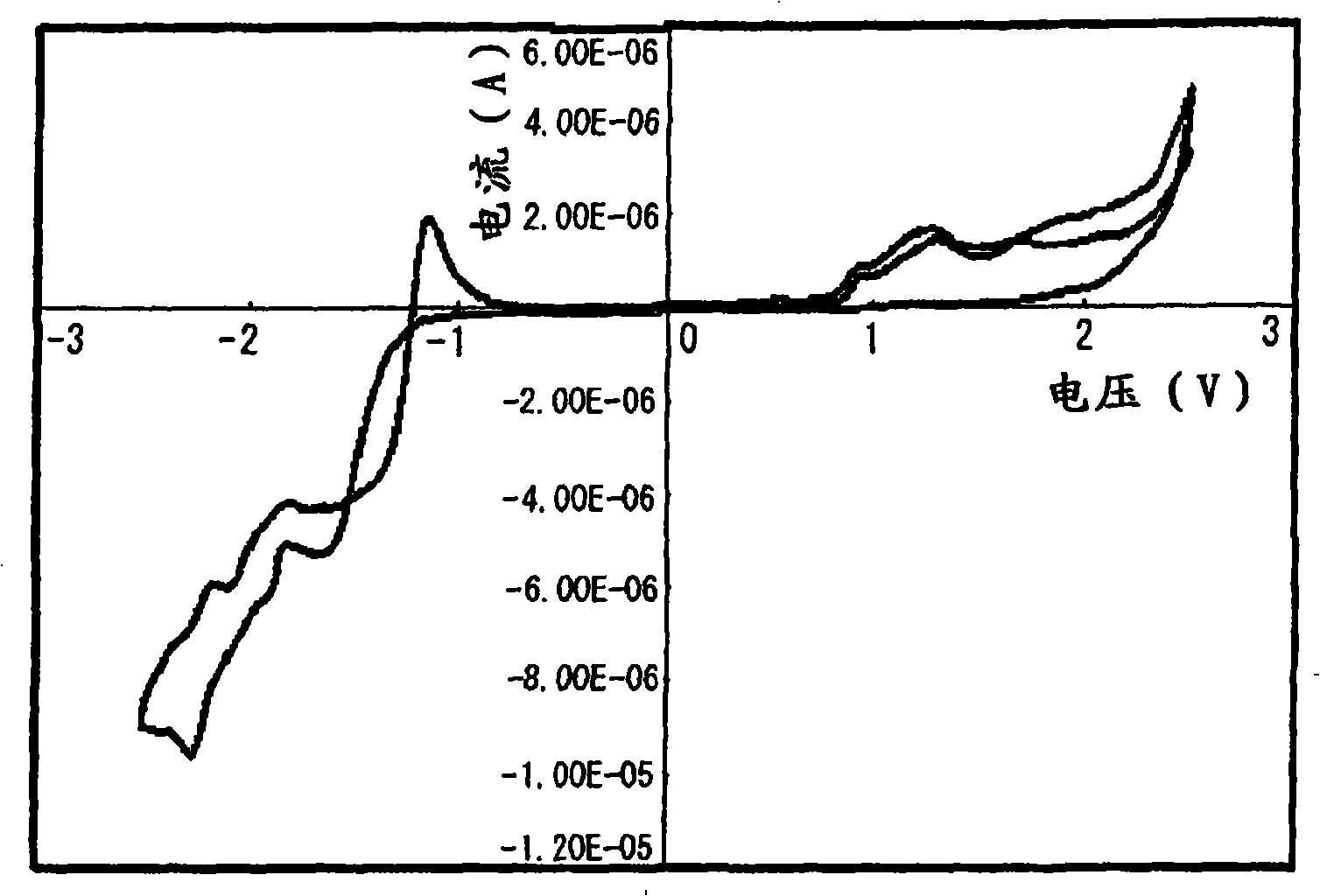

Image

Examples

preparation example Construction

[0449] The preparation method comprising the above-mentioned steps 1 to 5-1 or 5-2 is most suitable for synthesizing wherein R 50 and R 51 Is the method of the compound of hydrogen atom.

[0450] No particular limitation is imposed on the production methods of the sulfonylthiophene oligomer compounds respectively represented by the general formulas [2] and [16], and the sulfonylbithiophene compounds respectively represented by the general formulas [19]-[22], they It can be obtained by converting the terminal substituent of the sulfonylthiophene compound represented by the general formula [1] or [24] into an appropriate substituent, and then causing coupling by a desired method described later herein. As for the obtained compounds represented by the general formulas [2] and [16] respectively, the terminal substituents of their thiophene rings (or other spacers represented by the general formulas [3]-[11] respectively) can be converted into suitable The substituents can then b...

Embodiment 13

[0541] [Example 1] 3, the synthesis of 4-bissulfonylthiophene

[0542] [chemical formula 88]

[0543]

[0544] 3,4-disulfanylthiophene compound 1a-f and ruthenium(III) chloride n-hydrate (0.05 equiv, commercial product) were added to the reaction vessel and stirred at room temperature until they were completely dissolved. The reaction vessel was cooled and sodium periodate (4.20 equiv, commercial product) was added in portions while keeping the solution at room temperature and watching for exotherm. After the addition was complete, the mixture was further stirred at room temperature for 5 hours. The reaction mixture was extracted with diethyl ether. The organic layer was washed three times with water, and dried over anhydrous sodium sulfate. The solvent was distilled off, and the obtained crude product was purified by silica gel column (ethyl acetate:hexane=1:2) to obtain the corresponding compound as a white solid 2a-f .

[0545] Table 1

[0546]

[0547] *AcO...

Embodiment 2

[0572] [Example 2] 3,4-bissulfonyl-2, the synthesis of 5-bis(tributylstannyl)thiophene

[0573] [chemical formula 89]

[0574]

[0575] The 3,4-bissulfonylthiophene obtained above 2a-f One was placed in a reaction vessel and then dissolved in THF under a nitrogen atmosphere. The solution was cooled to -78°C. n-Butyllithium (1.58M hexane solution, 2.20 equivalents, commercial product) was gradually added dropwise, and the resulting mixture was stirred at the same temperature for 1 hour. Subsequently, tributylstannyl chloride (2.50 equivalents, commercial product) was added dropwise, followed by stirring for 3 hours. After completion of the reaction, disodium hydrogen phosphate / sodium dihydrogen phosphate buffer adjusted to pH 7 was added to terminate the reaction, and the reaction mixture was extracted with ethyl acetate. The organic layer was washed with saturated brine and dried over anhydrous sodium sulfate. The solvent was removed, and the resulting crude product w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rate of recovery | aaaaa | aaaaa |

| rate of recovery | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com