Preparation of one-dimensional Fe3O4 nano-needle material having modulated structure

A nano-needle and conductive metal technology, applied in nano-materials and nano fields, can solve problems such as difficult and stable physical phases, and achieve the effects of low equipment requirements, high degree of controllability and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A 1D Fe with modulated structure 3 o 4 The preparation method of nanoneedle material, it comprises the steps:

[0029] 1) Dissolve ferrous chloride, boric acid, saccharin and sodium fluoride in distilled water, then adjust the pH value to 2.0 by adding dilute sulfuric acid or sodium hydroxide aqueous solution dropwise, prepare an electrolyte solution, and place it in a Hull cell; Mix per liter of electrolyte: ferrous chloride 380g, boric acid 20g, saccharin 5g, sodium fluoride 2.5g; (note: the volume is determined by a standard Hull cell with a capacity of 267ml, when the volume of electrolyte required by the Hull cell is 1 Timing, the amount of ferrous chloride, boric acid, saccharin, sodium fluoride, distilled water can be determined);

[0030] 2) Using the pulse electrodeposition technology, adopt the pulse electrodeposition parameters with the output pulse frequency f of 50-500Hz, the duty cycle r of 5-50%, the positive pulse working current of 0.3-0.5A, and the n...

Embodiment 2

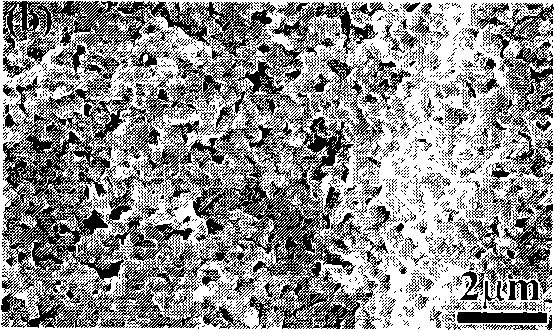

[0040] Embodiment 2: (research the one-dimensional Fe prepared by different thermal oxidation time 3 o 4 Changes in morphology and microstructure of nanoneedle materials):

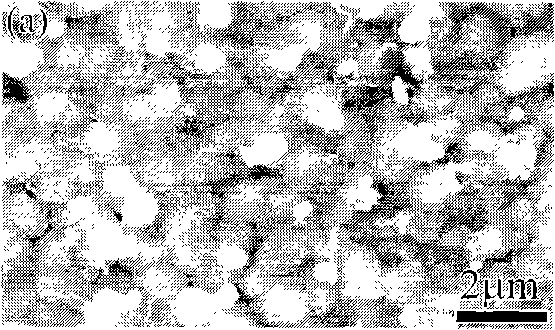

[0041] The preparation is basically the same as in Example 1, except that the nanocrystalline Fe film is heated at 900° C. in air for 3 hours, and the SEM photo of the scanning electron microscope is shown in Figure 2b .

[0042] to combine Figure 2a , Figure 2b Explanation: The SEM photo of the synthesized product shows that when the thermal oxidation time exceeds 30 minutes, the morphology and density of the thermal oxidation product no longer change significantly.

Embodiment 3

[0047] A 1D Fe with modulated structure 3 o 4 The preparation method of nanoneedle material, it comprises the steps:

[0048] 1) Dissolve ferrous chloride, boric acid, saccharin and sodium fluoride in distilled water, then adjust the pH value to 2.0 by adding dilute sulfuric acid or sodium hydroxide aqueous solution dropwise, prepare an electrolyte solution, and place it in a Hull cell; For each liter of electrolyte: 380g of ferrous chloride, 20g of boric acid, 5g of saccharin, 2.5g of sodium fluoride;

[0049] 2) Adopt the pulse electrodeposition technology, adopt the pulse electrodeposition parameters of output pulse frequency f as 50Hz, duty ratio r as 5%, positive pulse working current 0.3A, negative pulse working current 0.1A; place the conductive metal substrate in the storage In the Hull cell with the electrolyte of step 1), the conductive metal substrate is connected to the cathode of the power supply, the anode of the power supply is connected to the standard anode,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com