Reducing smelting furnace for regenerating metals

A technology for regenerating metal and smelting furnace, applied in the field of smelting equipment, can solve the problems of indirect return of flue ash into the furnace, difficult mechanized operation, poor working environment, etc., so as to improve product quality, improve equipment production efficiency, and improve direct yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

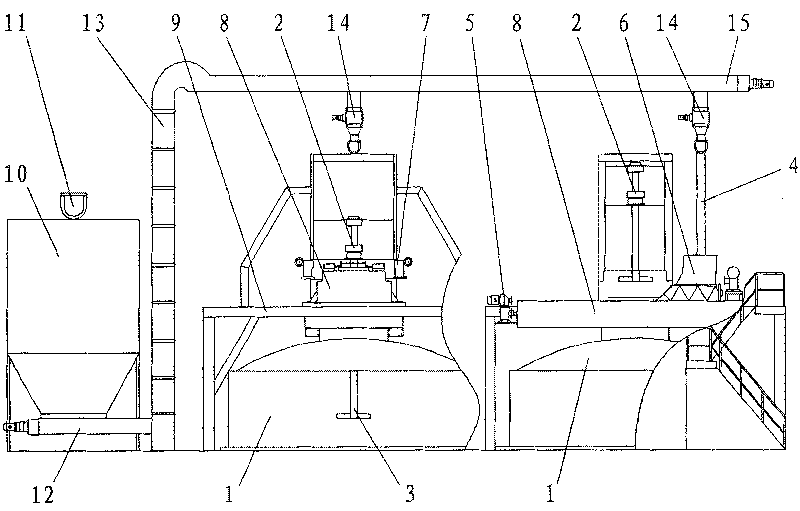

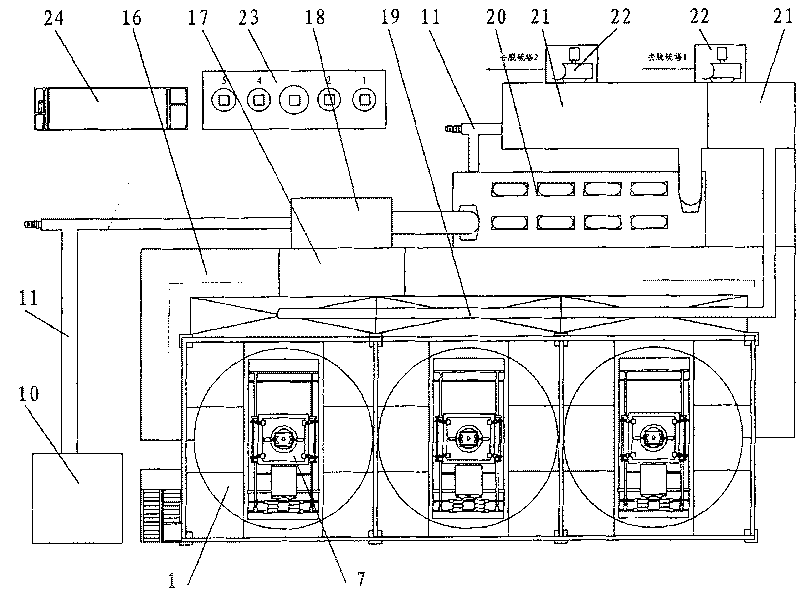

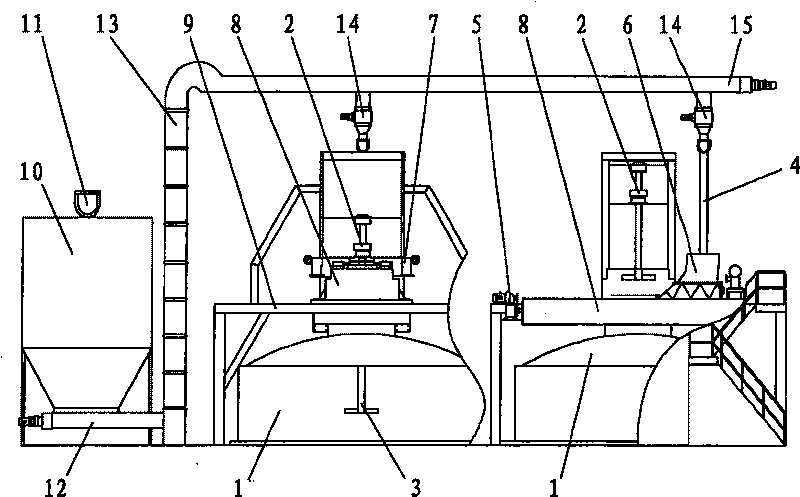

[0018] Embodiment 1: among the figure, 1, furnace body; 2, mixer; 3, stirring paddle; 4, stirring shaft; 5, gate hoist; 6, feeder; 7, elevator; 8, sealing cover; 9, Bracket; 10. Storage tank; 11. Smoke and dust recovery pipe; 12. Smoke and dust conveyor; 13. Smoke and dust hoist; 14. Ash unloading valve; 15. Flue dust conveyor; 16. Fire passage; 17. Waste heat steam generator ; 18. Heat exchanger; 19 Suction hood; 20. Water shower cooling tower; 21. Pulse dust collector; 22. Fan; 23. Cyclone desulfurization tower;

[0019] The smelting furnace includes a furnace body, a stirring device, a waste gas treatment device and a smoke recovery device. There are at least two furnace bodies, and a fire passage is connected between the furnace bodies; The upper end of the furnace, the exhaust gas treatment device and the dust recovery device are located on the side of the furnace body. The gate is connected with the gate hoist; the feeder is a screw conveyor, and the gate hoist and the ...

Embodiment 2

[0030] Embodiment 2: There are multiple furnace bodies, which are hexagonal; the sealer has a sealing cover and a flue gas sealing plate. Others are the same as embodiment 1, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com