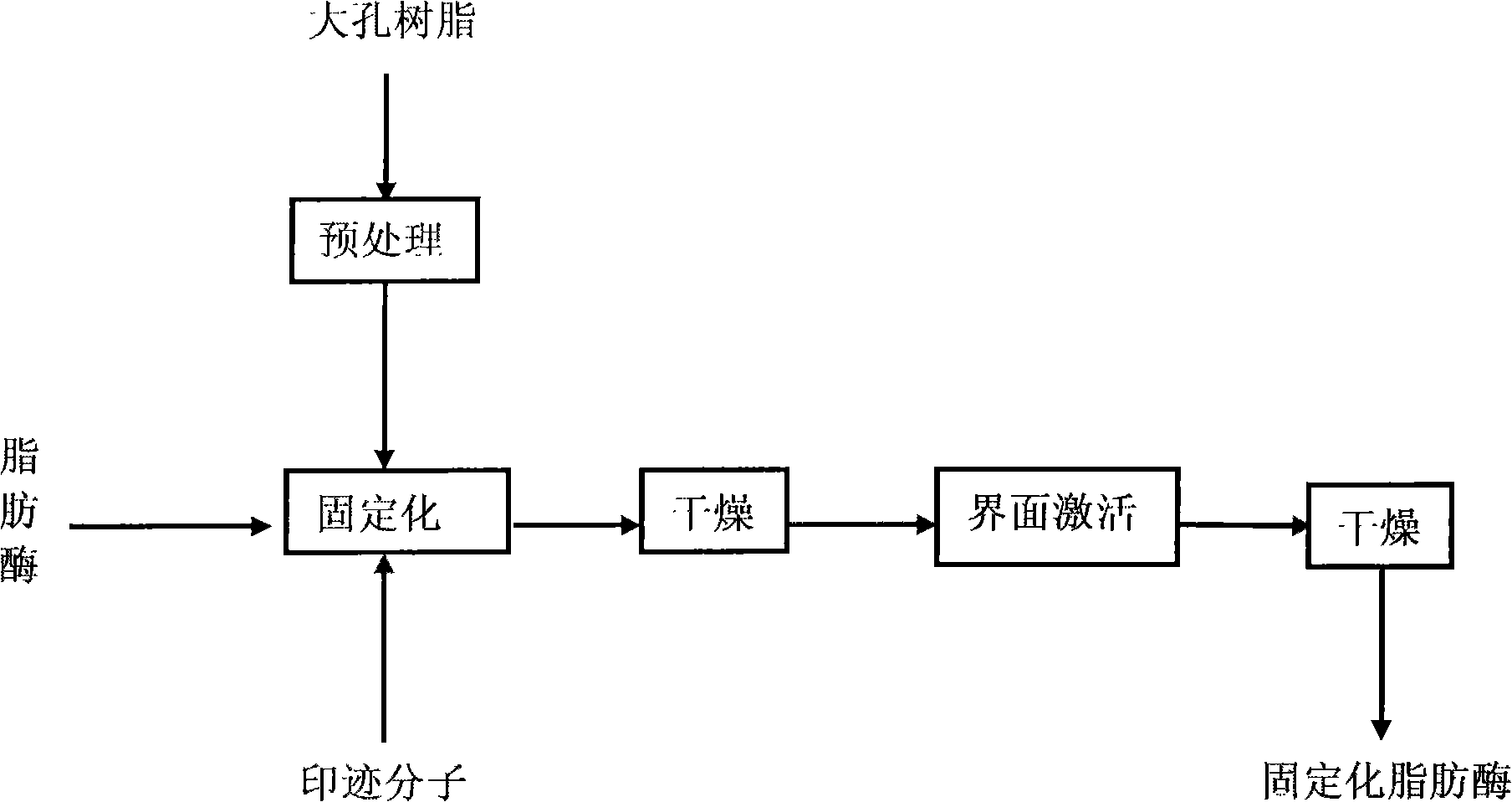

Preparation of immobilized lipase

A technology of immobilizing lipase and resin, which is applied in the direction of immobilizing on/in organic carriers, can solve the problems of large influence on enzyme activity, high temperature resistance of lipase, and the failure of biodiesel to be popularized and industrialized, and achieve catalytic Good effect, high enzyme immobilization rate, and many batches of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 1.1242g of NKA polystyrene macroporous resin, add 5mL of absolute ethanol to soak for 2h, remove ethanol and wash with distilled water 4 times, add 5mL of sodium phosphate buffer solution with a concentration of 0.05mol / L and a pH of 6.8 Equilibrate for 8 hours, remove the buffer, then add 2.5mL of lipase solution with a concentration of 160mg / mL and 10μmol lauric acid, place at 37°C, set the speed at 150rpm and oscillate for 1h, then take it out and filter, and wash with sodium phosphate After washing with the buffer solution for 3 times, vacuum-dry for 4 hours at a vacuum degree of 20 Pa and a drying temperature of -50°C. Finally, 125 mL of activator (n-hexane, heptane) was added, and after the interface activation treatment at 37°C for 1 hour, the immobilized lipase was placed in a fume hood to completely evaporate the organic solvent to obtain the immobilized lipase product. The lipase immobilization rate was determined to be 96%, and the specific enzyme activ...

Embodiment 2

[0018] Weigh 1.0042g of AB-8 polystyrene macroporous resin, add 5mL of absolute ethanol to soak for 2h, remove the ethanol and wash with distilled water 4 times, add 8mL of sodium phosphate buffer solution with a concentration of 1.00mol / L and a pH of 7.2 Equilibrate the solution for 12 hours, remove the buffer, then add 8.0mL of lipase solution with a concentration of 160mg / mL and 60μmol lauric acid, place it at 37°C, set the speed at 280rpm and oscillate for 4h, then take it out and filter it, and wash it with phosphoric acid After washing with sodium buffer solution for 3 times, vacuum-dry for 10 h at a vacuum degree of 20 Pa and a drying temperature of -50°C. Finally, 105 mL of activator (n-hexane, heptane) was added, and after interfacial activation treatment at 37°C for 2 hours, the immobilized lipase was placed in a fume hood to completely evaporate the organic solvent to obtain the immobilized lipase product. The lipase immobilization rate was determined to be 89%, and...

Embodiment 3

[0020] Raw materials: take 100g of Chinese tallow tree oil

[0021] First, put the raw material oil into the reaction kettle, add 4g of immobilized lipase (the carrier is NKA polystyrene macroporous resin) and 20mL of methanol in sequence, turn on the constant temperature water bath control switch and the internal circulation control switch, when the temperature rises to 40°C , timed to carry out the transesterification reaction, stop the reaction after 20 hours of reaction, emit 98.6g of esterification product from the liquid outlet of the reactor, let it stand for stratification, collect the light phase liquid, reclaim methanol by vacuum distillation, and the conversion rate of biodiesel is 97% . The result of repeated utilization of the immobilized lipase of the present invention shows that the conversion rate of biodiesel is still 95% after repeating 200 batches.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com