Pure rose wine and preparation thereof

A rose vinegar and purebred technology, applied in the field of food fermentation engineering, can solve the problems of scale and output, difficult to guarantee quality, uneven products, etc., to achieve stable fermentation process, improved pass rate, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] 1 Test environment

[0023] · Venue: Hangzhou Food Brewing Co., Ltd.

[0024] ·Laboratory conditions: 10m 2 In the room, use oil to control the room temperature to 25°C

[0025] ·Fermentation container: 500kg cylinder is used as the fermentation container, and the mouth of the cylinder is kept warm with a grass cover

[0026] 2 test process

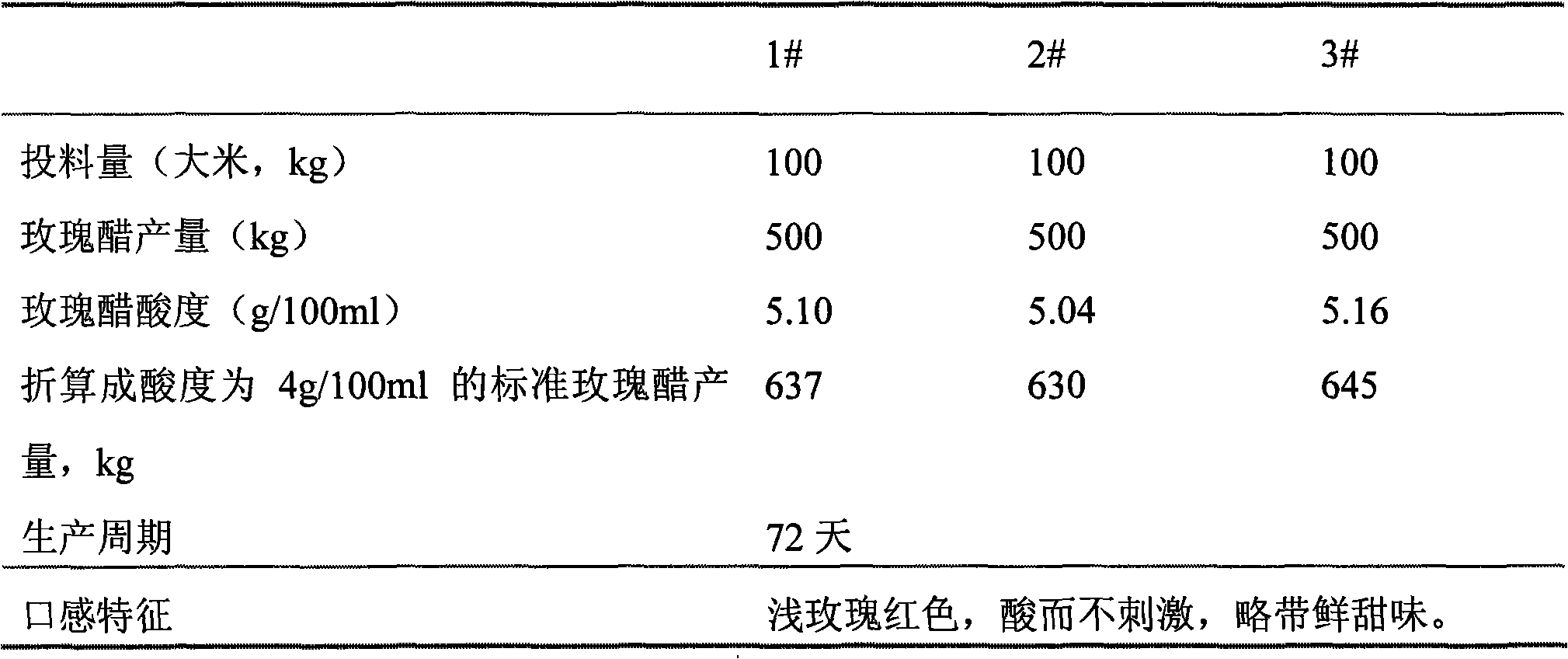

[0027] ·According to the method of large-scale production, take three 500kg barrels and put 200kg rice in each. The 1#, 2#, 3# barrels are inserted with a total amount of 0.8% mixed koji (koji niger: rhizopus=0.8: 1) for flowering, and the reducing sugar content of the rice base after flowering after 7 days reaches 38.8%- 44.3%. After flowering, flush the cylinder with rice: water (w / w)=1:5 to release water, and insert mixed yeast strains (Saccharomyces cerevisiae: Torulopsis globosa=3:1) according to the total inoculum size of 5% to carry out alcoholic fermentation. After 8 days, the alcohol content reaches 6.5-7.3%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com