Molybdenum, nickel, phosphorus soaking solution and preparation thereof

A technology of impregnating solution and solution, which is applied in the field of impregnating solution used in hydroprocessing catalysts and its preparation, which can solve the problems of metal deposition, strong interaction, loss of carrier specific surface area, etc., and achieve high catalyst activity, stable solution properties, and strong force Appropriate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

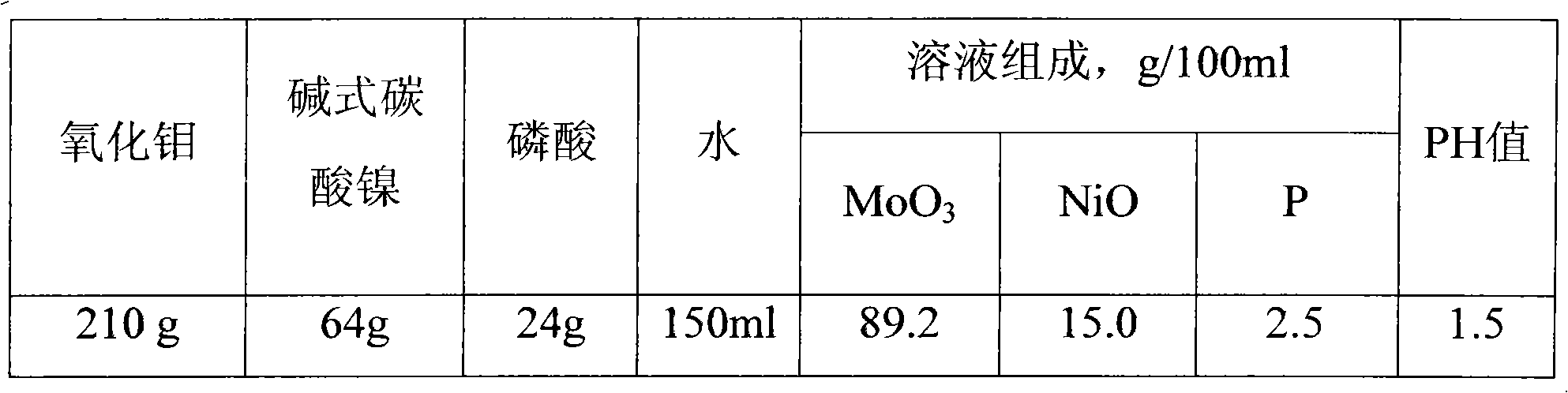

[0014] This example introduces the preparation method of Mo, Ni, P original solution. In this example, only Mo, Ni, and P original solutions with one concentration and ratio are prepared. According to the method described, Mo, Ni, and P original solutions with other ratios and concentrations can be prepared as required, so as to prepare the desired target solution.

[0015] Get a certain amount of molybdenum oxide and basic nickel carbonate into a multi-necked flask, add a certain amount of deionized water, stir until the substance in the bottle is slurry, then slowly add a certain amount of phosphoric acid (weight concentration 85%) After the initial reaction, heat slowly, and keep the solution temperature at 90-110° C. for 1-3 hours (choose the holding time according to the transparency of the solution). After the heating was stopped, the obtained solution was filtered while it was hot, and after some insoluble impurities were filtered out, a clear dark green original soluti...

Embodiment 2

[0019] This example introduces the addition of ammonia solution of EDTA to the original solution to prepare target solutions with different pH values.

[0020] First prepare the ammonia solution of EDTA, weigh 100g EDTA and put it into a round bottom flask, add 50ml water and 70g concentrated ammonia water respectively (concentrated ammonia water contains NH 3 The mass percent concentration is about 26% to 28%), stirring and dissolving at room temperature.

[0021] Put a certain volume of original solution of Mo, Ni, and P into a beaker, and slowly add the ammonia solution of EDTA dropwise under the condition of constant stirring, pay attention to the dropping speed not too fast, so as not to generate stable insoluble matter. Measure the pH value of the solution in time with a pH meter, stop dropping the EDTA solution when the required pH value is reached, and continue stirring until the flocs in the solution are completely dissolved. Finally, an appropriate amount of water w...

Embodiment 3

[0025] In this embodiment, the ammonia solution of NTA is added to the original solution to prepare target solutions with different pH values.

[0026] Preparation of ammonia solution of NTA: Weigh 100g NTA and put it into a round bottom flask, add 50ml water and 100g concentrated ammonia water respectively (concentrated ammonia water contains NH 3 The mass percent concentration is about 26% to 28%), stirring and dissolving at room temperature.

[0027] The method of adding the NTA solution in the original solution is as in Example 2, and Table 3 provides the preparation parameters of two groups of pH Mo, Ni, and P solutions. The concentration of each substance (metal concentration is calculated as oxide) in the target solution 4 is: MoO 3 is 64.9g / 100ml, NiO is 10.9g / 100ml, and P is 1.8g / 100ml; the concentration of each substance in the target solution 5 (the metal concentration is calculated as oxide) is: MoO 3 30.2g / 100ml, NiO 5.1g / 100ml, P 0.8g / 100ml

[0028] Table 3 Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com