Last stage pressure reducing device

A decompression device and pressure reducer technology, which is applied in the direction of oil supply device, charging system, internal combustion piston engine, etc., can solve the problems of small engine displacement, exhaust gas not up to standard, insufficient combustion, etc., and achieve mobility Strong, low fuel consumption, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

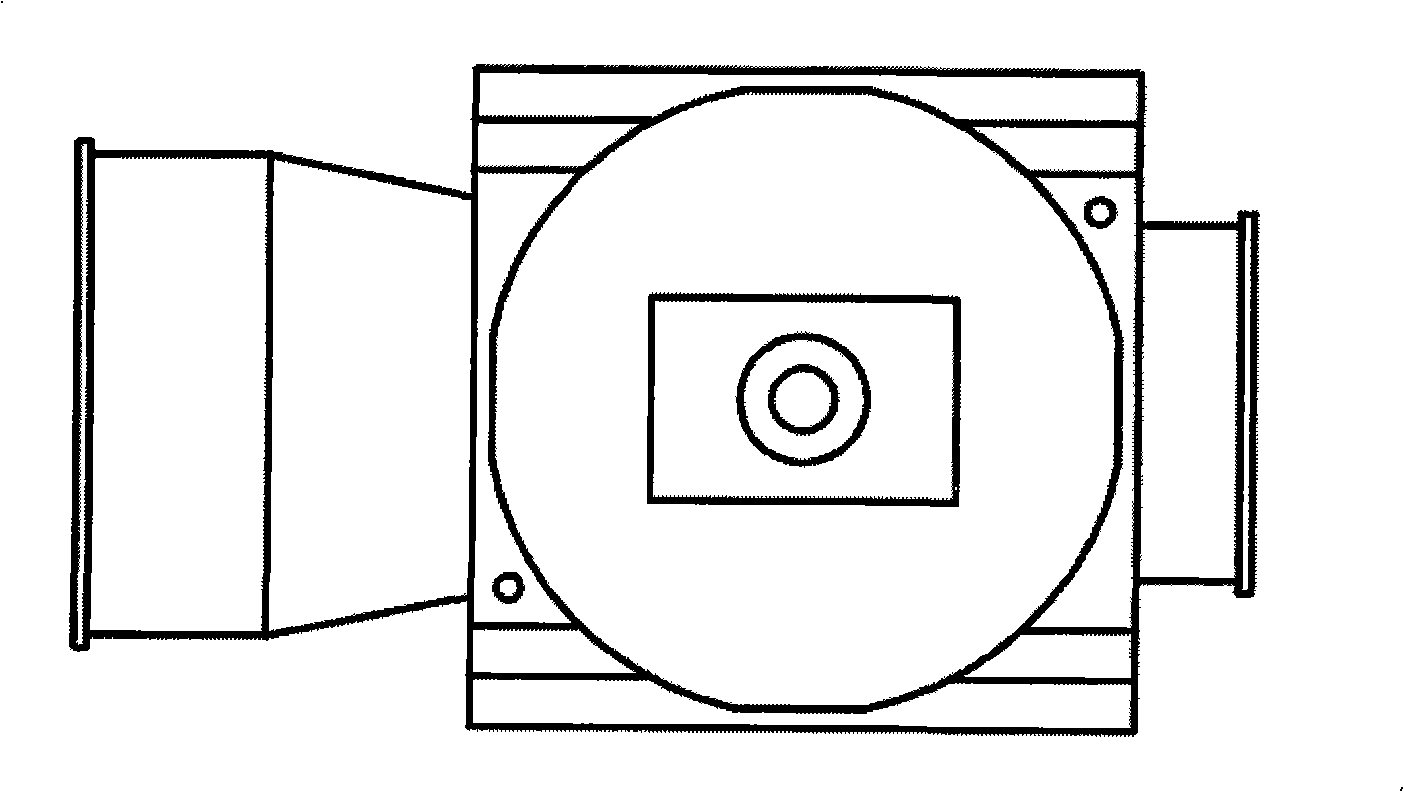

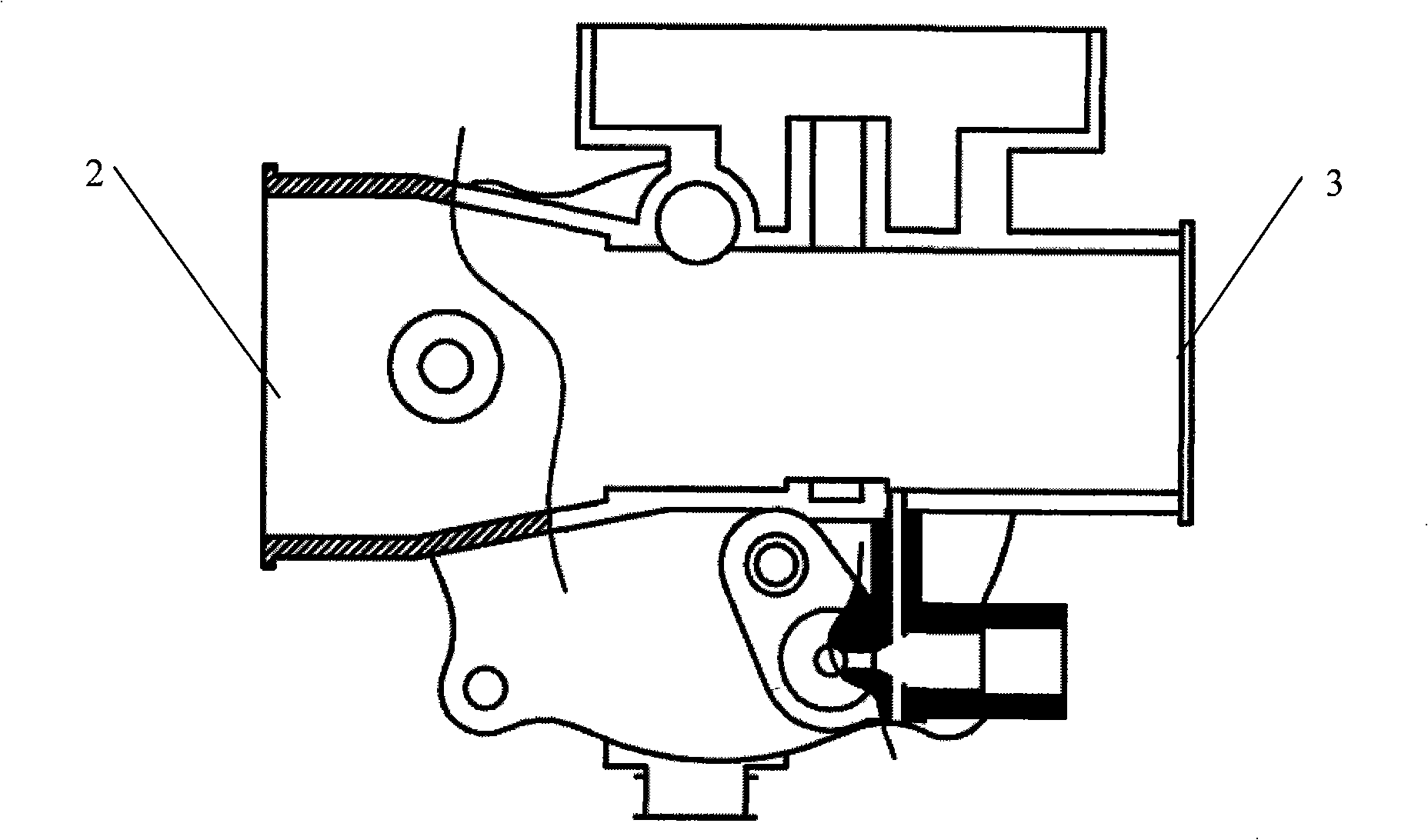

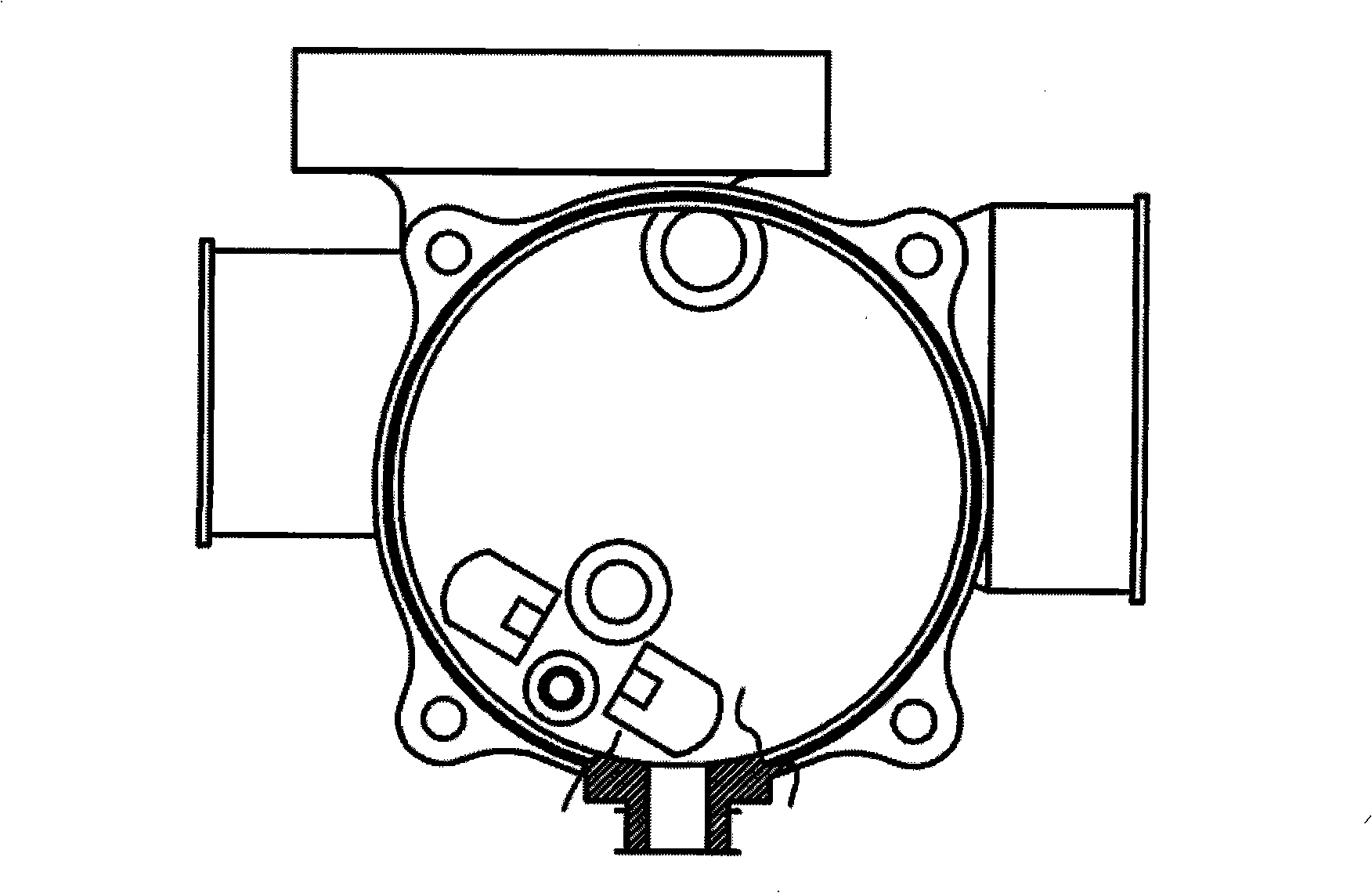

[0020] see Figure 1 to Figure 5 , the final decompression device, including a pressure reducer, a primary decompression gas pipeline, a secondary decompression gas pipeline and a total gas pipeline, the pressure reducer body has a regulating valve and a mixer, the regulating The valve, mixer and pressure reducer are integrated.

[0021] The regulating valve is arranged at the air inlet position of the pressure reducer.

[0022] The mixer is arranged downstream of the pressure reducer.

[0023] As shown in the figure, the gas inlet 1 of the pressure reducer, the air inlet 2, the engine interface 3, the regulating valve 4 (not shown in the figure), and the mixer 5 (not shown in the figure) are arranged on the pressure reducer Inside the body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com