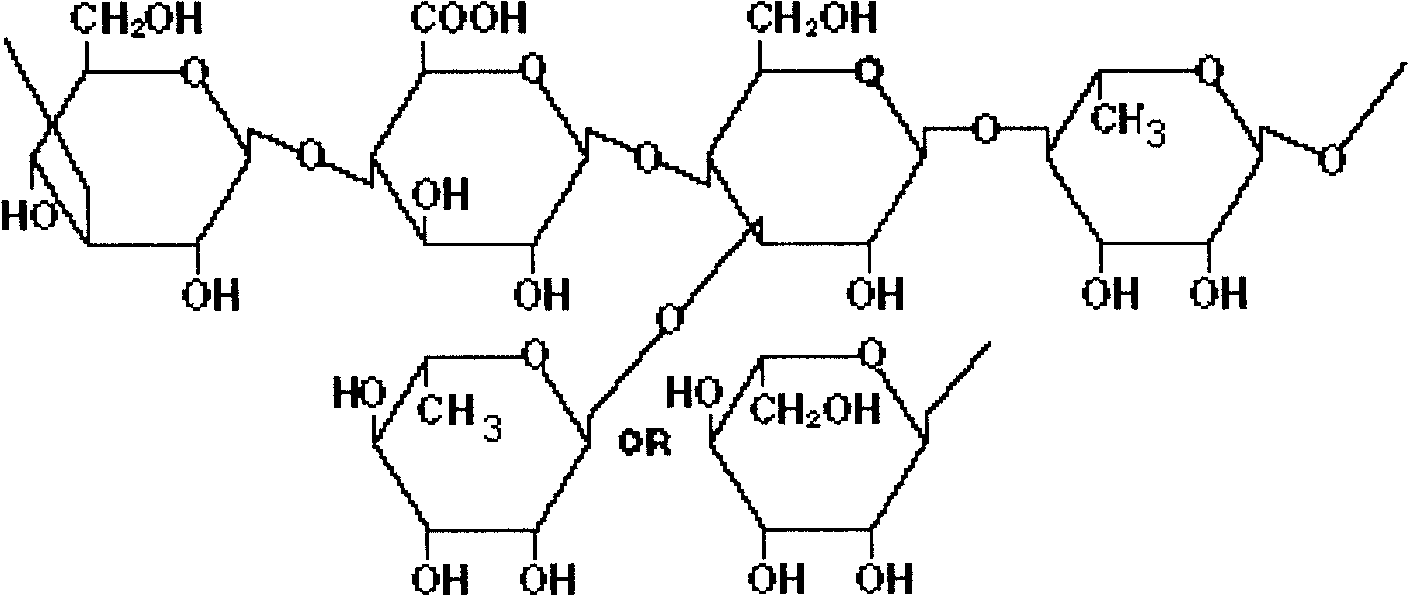

Production method for microbial polysaccharide welan gum

A production method, sugar welan gum technology, applied in the field of bioengineering, can solve the problems of increasing investment cost and production cost, high energy consumption, etc., and achieve the effect of promoting green production, reducing pollution, reducing investment cost and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1. the production of microbial polysaccharide welan gum

[0025] Strains Alcaligenes ATCC 31555.

[0026] The seed medium used is (g / L): glucose 10, ammonium nitrate 0.6, yeast powder 2.5, peptone 5, KH 2 PO 4 0.5, MgSO 4 0.1, pH6.8, sterilized at 121°C for 20min.

[0027] Fermentation medium used (g / L): glucose 10, sucrose 1, yeast powder 1.0, urea 1, dipotassium hydrogen phosphate 0.5, MgSO 4 0.1, pH 6.0, sterilized at 121°C for 20min.

[0028] The feed medium used (g / L): glucose 400, yeast powder 10, urea 40, and ammonia water 12.5% (v / v).

[0029] Fermentation was carried out on a 15L Biostat C10-3 mechanical stirring tank, the inoculum size was 5% (v / v), the liquid filling volume was 9L, the stirring speed of the fermenter was 500r / min, the ventilation intensity was 1.0vvm, and the tank pressure was maintained at 0.01MPa. The temperature is 30° C., and the pH value of the fermentation broth is controlled by feeding medium, and the pH is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com