Method for preparing dihydrochalcone molecular imprinting solid phase extraction column filler material

A technology of dihydrochalcone and solid phase extraction column, which is applied in chemical instruments and methods, other chemical processes and other directions, can solve the problems of complex composition of natural products, low content of dihydrochalcone, poor selectivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

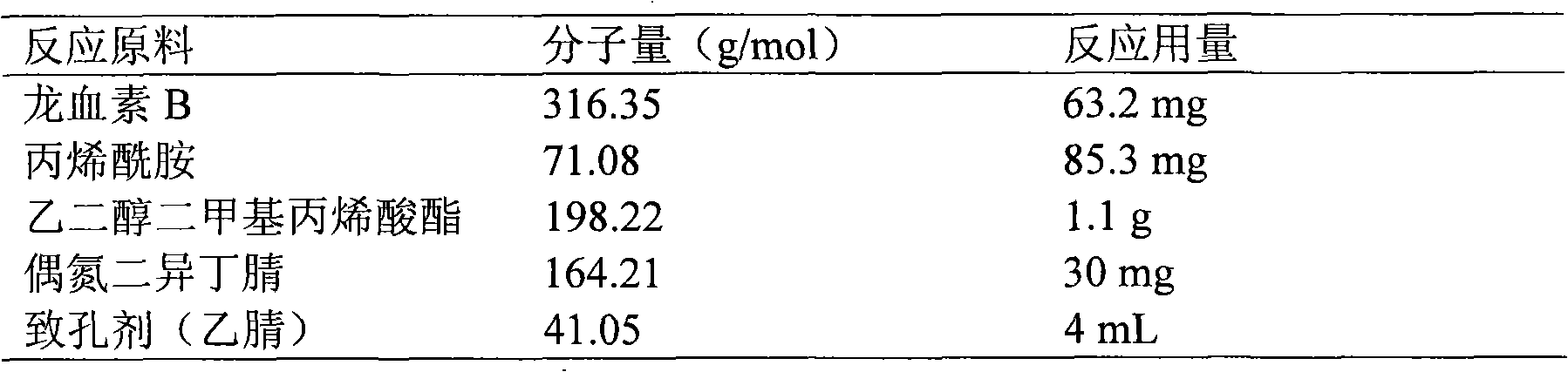

[0015] Example 1: Preparation of packing materials for the molecularly imprinted solid phase extraction column of dragon blood B, see Table 1 for the specific raw materials and dosage.

[0016] Table 1 Reaction raw materials and consumption

[0017]

[0018] 1. The reaction raw material template molecule loureirin B (Loureirin B), functional monomer acrylamide, crosslinking agent ethylene glycol dimethacrylate and porogen acetonitrile are added to the grinding port successively according to the consumption of table 1 In the three-neck flask, ultrasonically mix for 30 minutes, after mixing evenly, add 30 mg of azobisisobutyronitrile, ultrasonic degassing for 10 minutes, nitrogen gas for 20 minutes, seal, and react in a water bath at 60°C for 24 hours to obtain crude dragon blood molecule B imprinted polymer;

[0019] 2. Grind the above-mentioned dragon blood B molecularly imprinted polymer to about 75 μm, put it into a Soxhlet extractor, and r...

Embodiment 2

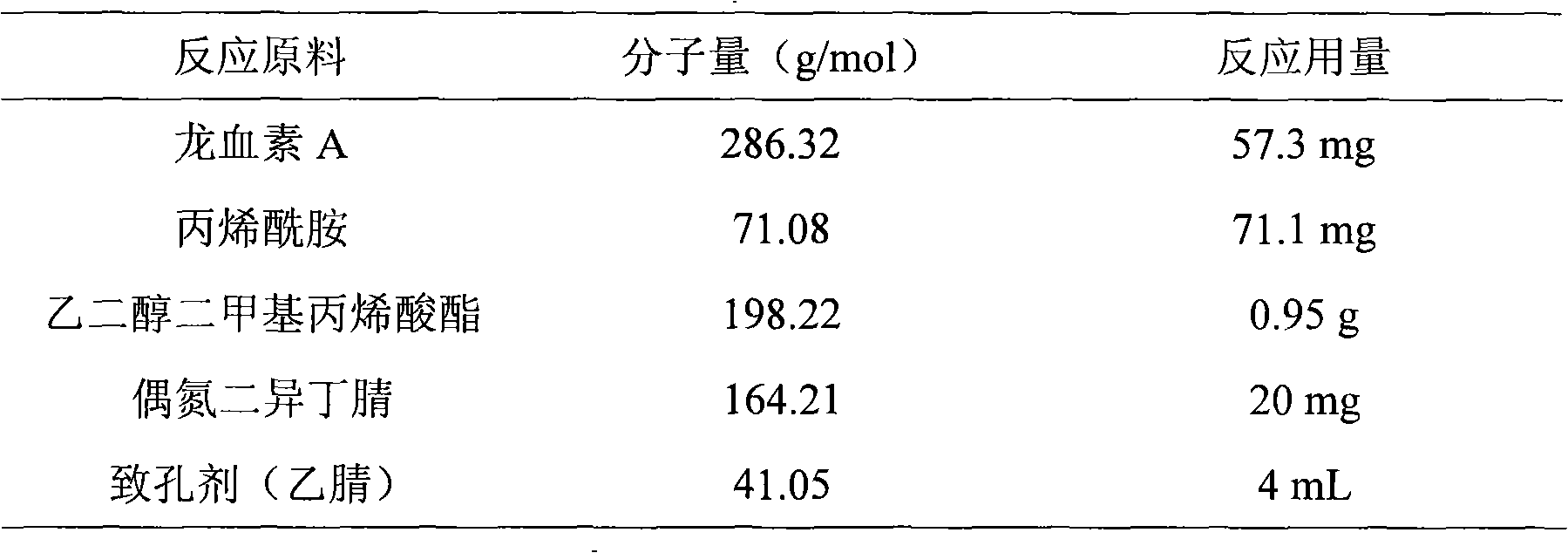

[0027] Example 2: Preparation of packing materials for the molecularly imprinted solid-phase extraction column of dragon blood A, see Table 2 for the specific raw materials and dosage.

[0028] Table 2 Reaction raw materials and consumption

[0029]

[0030] 1. Add the reaction raw material Loureirin A (Loureirin A), the functional monomer acrylamide, the crosslinking agent ethylene glycol dimethacrylate and the porogen acetonitrile to the three-neck bottle with a ground mouth according to the dosage in Table 2. In the process, ultrasonically mix for 20 minutes, after mixing evenly, add 20 mg of azobisisobutyronitrile, ultrasonically degas for 15 minutes, pass nitrogen gas for 20 minutes, seal, and react in a water bath at 60°C for 36 hours to obtain a molecularly imprinted polymer of dragon blood A;

[0031] 2. Grind the above-mentioned dragon blood A molecularly imprinted polymer to about 75 μm, put it into a Soxhlet extractor, and use a mixed sol...

Embodiment 3

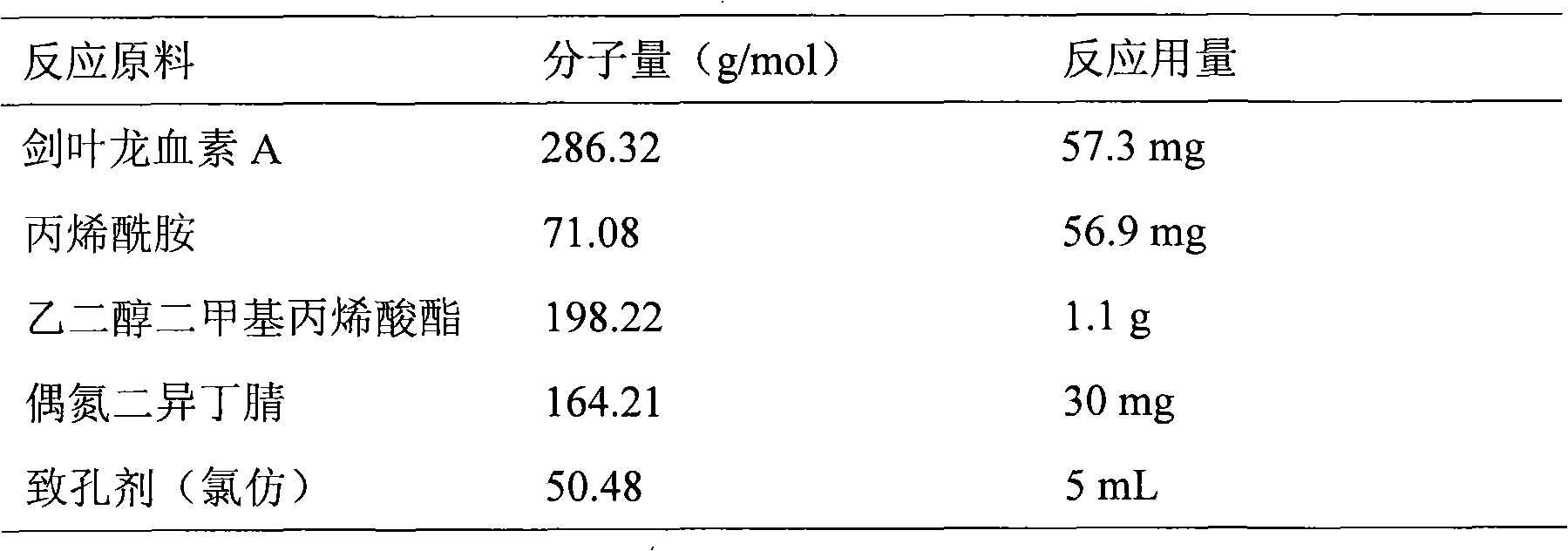

[0039] Example 3: Preparation of filling materials for phoenixin A molecularly imprinted solid-phase extraction column, the reaction raw materials and dosage are shown in Table 3.

[0040] Table 3 Reaction raw materials and consumption

[0041]

[0042] 1. Add the reaction raw material cochinchinenin A (cochinchinenin A), functional monomer acrylamide, cross-linking agent ethylene glycol dimethacrylate and porogen chloroform to the grinding port according to the consumption of Table 3 In the three-necked bottle, ultrasonically mix for 40 minutes, after mixing evenly, add 30 mg of azobisisobutyronitrile, ultrasonic degassing for 10 minutes, nitrogen gas for 20 minutes, seal it, and react in a water bath at 55°C for 36 hours to obtain crude phoenixin A molecularly imprinted polymer;

[0043] 2. Grind the above molecularly imprinted polymer of stegophyllin A to about 75 μm, put it into a Soxhlet extractor, and repeatedly extract it with a mixed solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com