A kind of high negative ion functional tourmaline grain solid surface material and preparation method thereof

A technology of tourmaline and negative ions, which is applied in the field of building decoration materials, can solve the problems of patent applications for solid surface materials without tourmaline grains, and achieve the effects of accelerating the elimination of harmful toxins in the body, preventing premature aging, and improving blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

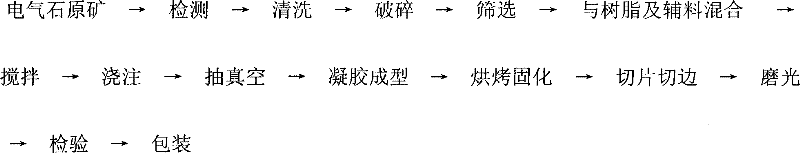

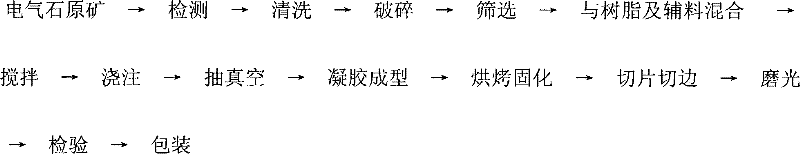

Method used

Image

Examples

Embodiment 1

[0031] The method for preparing matte polyester type high negative ion far-infrared tourmaline crystal grain surface material:

[0032] 1) Use the EB-15 negative ion tester to test and screen the natural tourmaline mineral raw materials, and select the static negative ion value ≥ 500ions / cm 3 Tourmaline mineral raw materials are used for standby;

[0033] 2) Use a crusher to crush the selected tourmaline raw ore into tourmaline grains, and sieve them into particle sizes of 0.25-5mm (accounting for 60% of the tourmaline grain weight) and 0.05-0.25mm (accounting for tourmaline grain weight). 40% of grain weight) two specifications, tourmaline raw ore grain weight accounts for 90% of product weight;

[0034] 3) adding unsaturated polyester resin (accounting for 10% of product weight) and modified silane coupling agent (accounting for 0.1%-1% of resin weight) to tourmaline crystal grains;

[0035] 4) After mixing and stirring the above types of raw materials, pour them into the ...

Embodiment 2

[0038] The method for preparing bright polyester type high negative ion far-infrared tourmaline crystal grain surface material:

[0039] 1) Use the EB-15 negative ion tester to test and screen the natural tourmaline mineral raw materials, and select the static negative ion value ≥ 500ions / cm 3 Tourmaline mineral raw materials are used for standby;

[0040] 2) Use a crusher to crush and process the selected tourmaline raw ore into tourmaline crystal grains, and the screening particle size is 0.25~5mm (accounting for 80% of the weight of tourmaline crystal grains) and 0.05~0.25mm (accounting for 80% of the weight of tourmaline crystal grains) and 0.05~0.25mm (accounting for 20% of grain weight) two specifications, tourmaline raw ore grain weight accounts for 80% of product weight;

[0041] 3) adding unsaturated polyester resin (accounting for 20% of product weight) and modified silane coupling agent (accounting for 0.1%-1% of resin weight) to tourmaline grains;

[0042] 4) Aft...

Embodiment 3

[0045] The method for preparing matte composite acrylic type high negative ion far-infrared tourmaline grain surface material:

[0046] 1) Use the EB-15 negative ion tester to test and screen the natural tourmaline mineral raw materials, and select the static negative ion value ≥ 500ions / cm 3 Tourmaline mineral raw materials are used for standby;

[0047] 2) Use a crusher to crush and process the selected tourmaline raw ore into tourmaline crystal grains, and the screening particle size is 0.25~5mm (accounting for 60% of the weight of tourmaline crystal grains) and 0.05~0.25mm (accounting for 60% of the weight of tourmaline crystal grains). 40% of grain weight) two specifications, tourmaline raw ore grain weight accounts for 70% of product weight;

[0048] 3) Add unsaturated polyester resin (accounting for 15% of product weight), methyl methacrylate (accounting for 15% of product weight) and modified silane coupling agent (accounting for 0.1% of resin weight) in tourmaline crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com