Method and device for reclaiming and utilizing billet residual heat

A technology of heat exchange device and steel billet, which is applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve the problem of no heat recovery and utilization, and achieve better energy-saving and economic effects, efficient recycling and utilization of water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

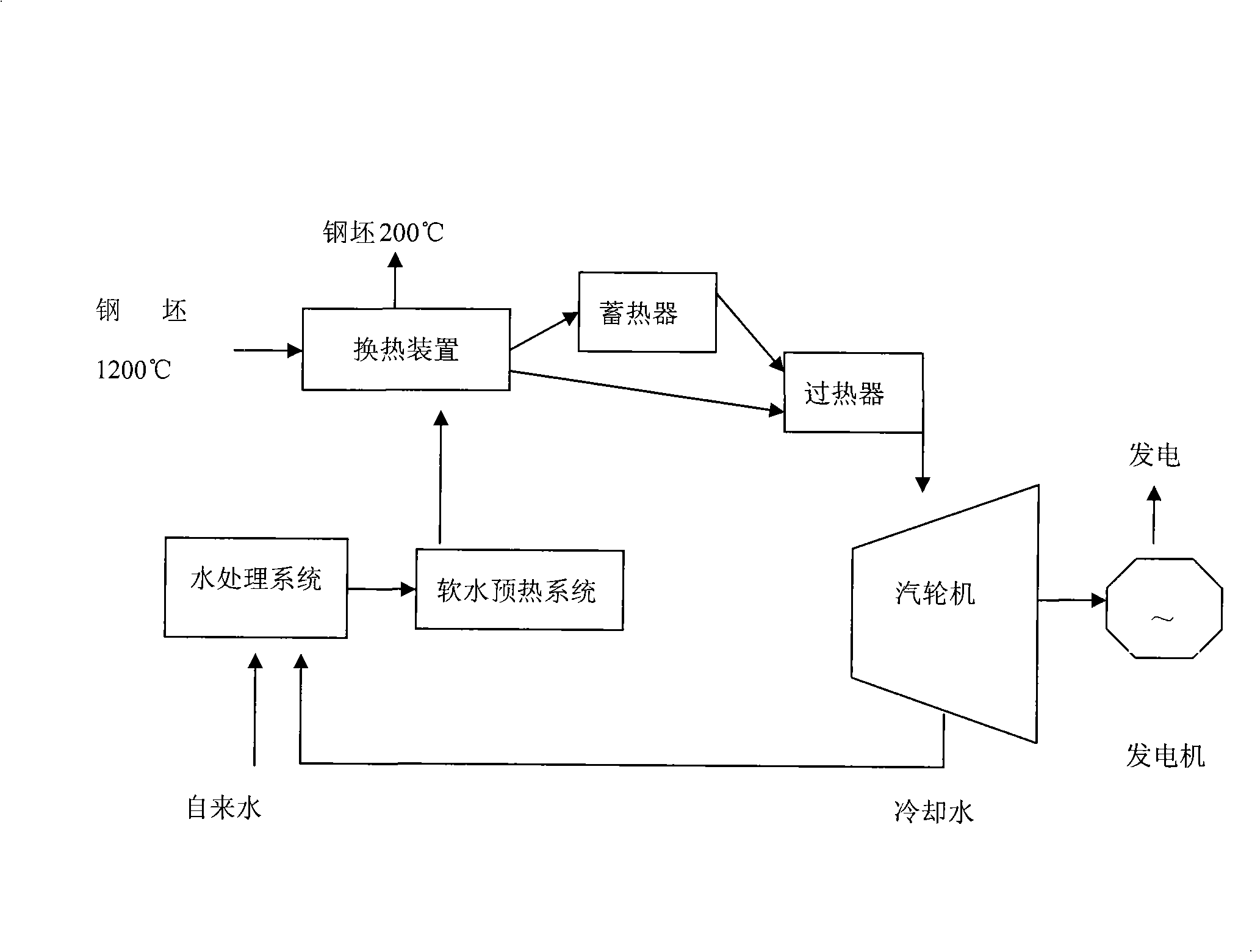

[0018] combine figure 1 The method and device of the present invention are described in detail: a method for recovering and utilizing the waste heat of steel slabs, using softened water, superheated water obtained through the steelmaking cooling system, and steam obtained by heat exchange of the superheated water with the discharged steel billet, The specific steps are:

[0019] A. Collect the superheated water obtained by softening tap water or cooling water into the water storage tank;

[0020] B. Use a high-pressure water pump to transport the superheated water in the water storage tank in step A to the steel pipe in the heat exchange device through the pipeline, push the steel billet into the heat exchange device surrounded by steel pipes, and the heat energy of the steel billet will be released to make the heat exchange device The water in it becomes high-temperature, high-pressure steam;

[0021] C. After passing the high-temperature and high-pressure steam into the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com