Synthetic resin container with high barrier capability

A technology for synthetic resins and containers, applied in the field of containers, can solve problems such as being unable to be effectively used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail with reference to the drawings.

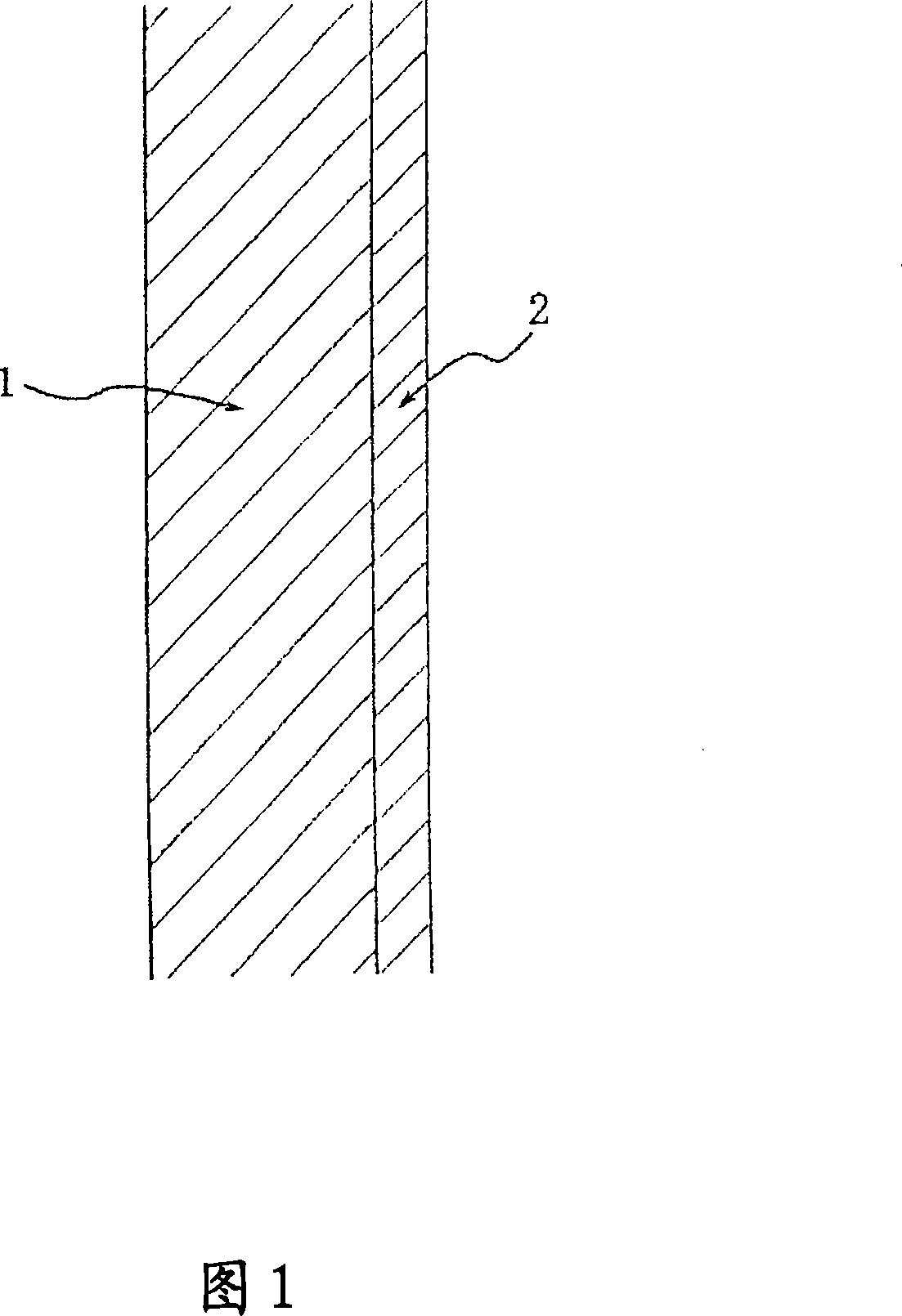

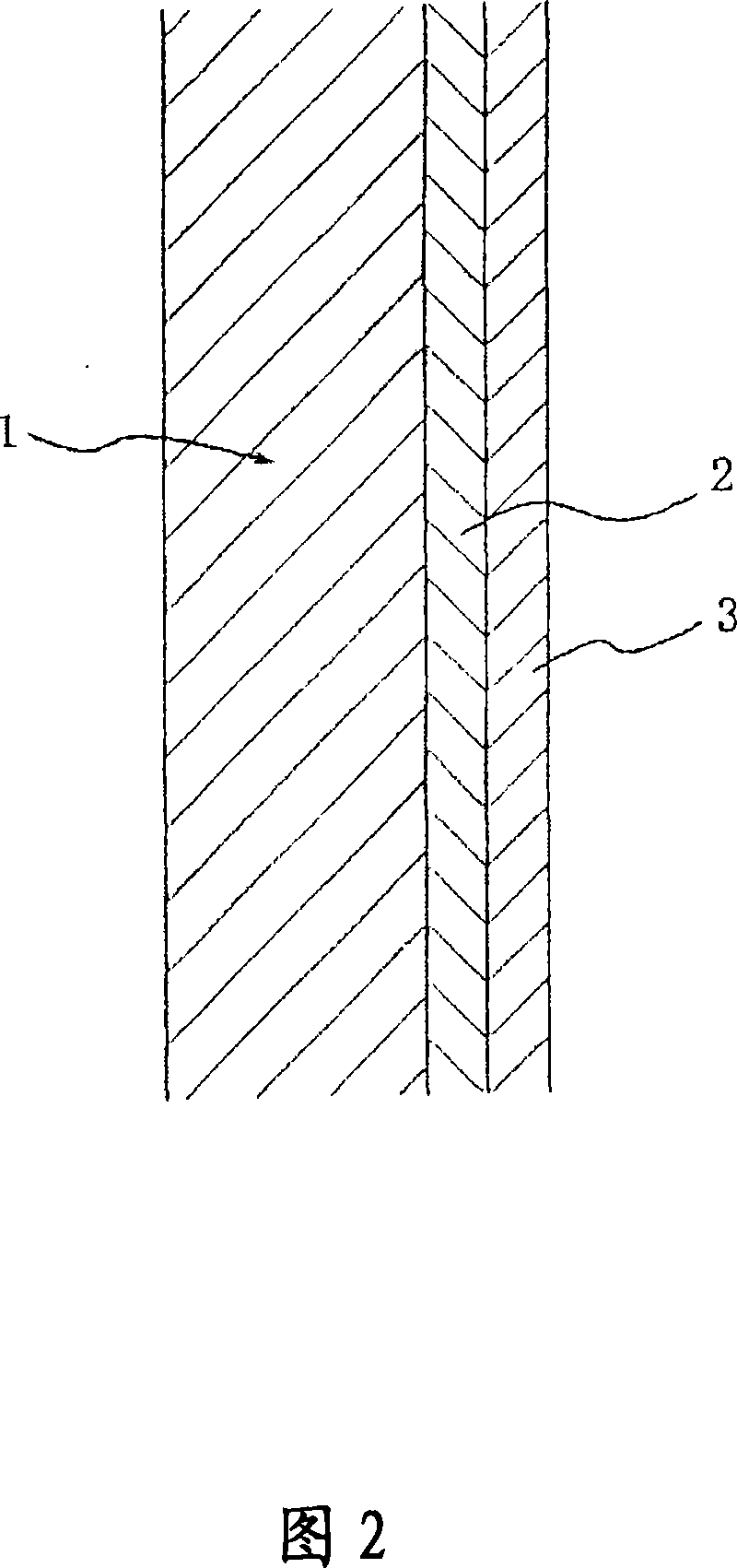

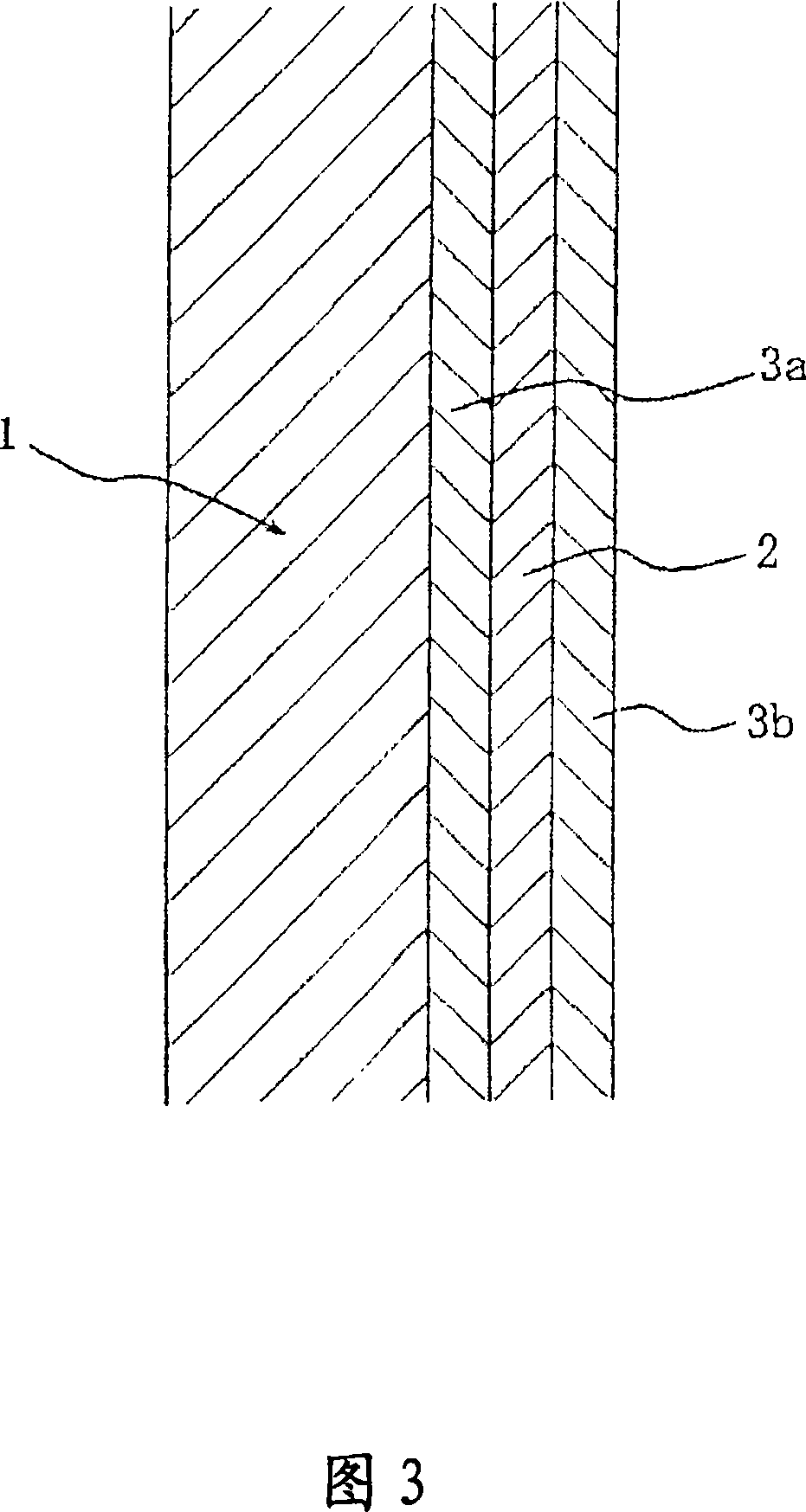

[0020] Fig. 1 shows the first embodiment of the present invention, which is represented by a bottle made of polyethylene terephthalate (hereinafter referred to as [PET bottle]) formed by biaxial stretch blow molding (blow) The enlarged cross-sectional view of the main part of the container, the number 1 is the wall that constitutes the container body, and the number 2 is the inner surface of the wall 1 that is used to prevent the gas (oxygen and carbon dioxide, etc.) from penetrating into the container or outside the container. ) and a high barrier coating for water vapor.

[0021] The coating film 2 is a barrier film made of silicon oxide disposed adjacent to the wall portion 1 . The barrier film 2 is composed of a compound formed of at least silicon (Si), carbon (C), hydrogen (H), and oxygen (O).

[0022] The barrier film 2 is formed by plasma chemical vapor deposition u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com