Printing plate material and process for producing printing plate

A printing plate and substrate technology, applied in printing, printing plate, printing plate preparation, etc., can solve the problems of poor developing performance, unexpectable printing resistance, slow ink adhesion, etc., achieve excellent printing resistance, prevent Excellent effect on scratches and stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0204]

[0205] The respective compositions in Table 1 were sufficiently mixed, stirred, and filtered to obtain coating liquids (1) to (5) for image forming layers having a solid content of 5%.

[0206] [Table 1]

[0207] Make up

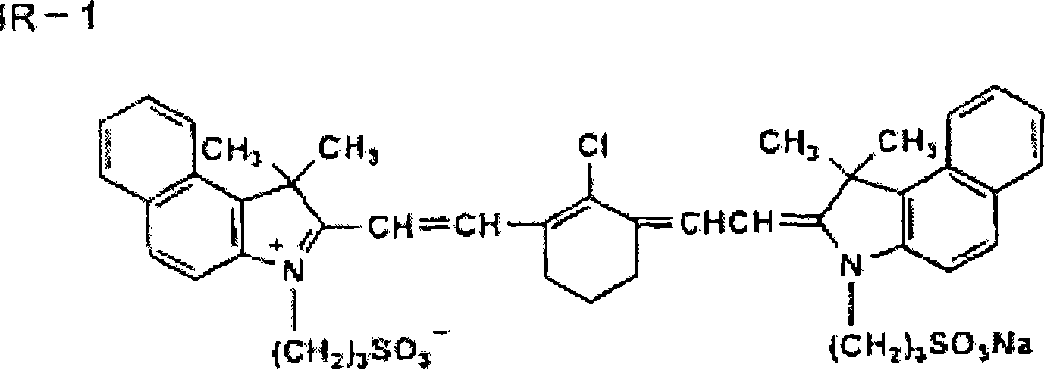

[0208] [Chemical formula 1]

[0209]

[0210]

[0211] On the surface of the lipophilic layer of the substrate 2, the image forming layer coating solutions (1) to (4) were respectively coated with a wire rod, and dried at 55°C for 3 minutes to obtain a positive printing plate material 1 ~4. Adjust the dry adhesion amount of the image forming layer to 0.8g / m 2 .

[0212] In addition, the above-mentioned image forming layer coating liquid (5) was coated on the surface of the hydrophilic layer of the substrate 3 with a wire rod, and dried at 55°C for 3 minutes to obtain a printing plate material 5 of a negative plate. Adjust the dry adhesion amount of the image forming layer to 0.8g / m 2 .

[0213]

[0214] For each of the obtained printing p...

Embodiment 2

[0238]

[0239] The respective compositions in Table 3 were sufficiently mixed, stirred, and filtered to obtain image forming layer coating liquids (6) to (9) having a solid content of 5%.

[0240] [table 3]

[0241] Make up

[0242] *1 Trimethylolpropane adduct of TDI, protective agent is oxime

[0243]

[0244] A film-forming acrylic emulsion with a solid content of 90% (WSA-900: manufactured by Dainippon Ink Co., Ltd.) and a stearic acid amide emulsion with a solid content of 10% (L-271: manufactured by Chukyo Oil Co., Ltd.) were mixed, and pure water was used. After diluting to a solid content of 5% in the liquid, it was filtered to obtain a coating liquid for a lipophilic cover coat layer.

[0245]

[0246] On the frosted surface of the above-mentioned base material 1, the image forming layer coating liquids produced in Examples 1 and 2 were respectively coated with a wire rod as shown in Table 4, and dried at 55°C for 3 minutes. The dry adhesion amount of the im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com