On-line annealing method and apparatus for rolling copper pipe

An annealing equipment and copper tube technology, applied in the field of metal tube rolling and forming, can solve problems such as unstable quality, long production cycle, uneven temperature, etc., achieve reliable oxidation resistance and service life, and improve and stabilize product quality , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

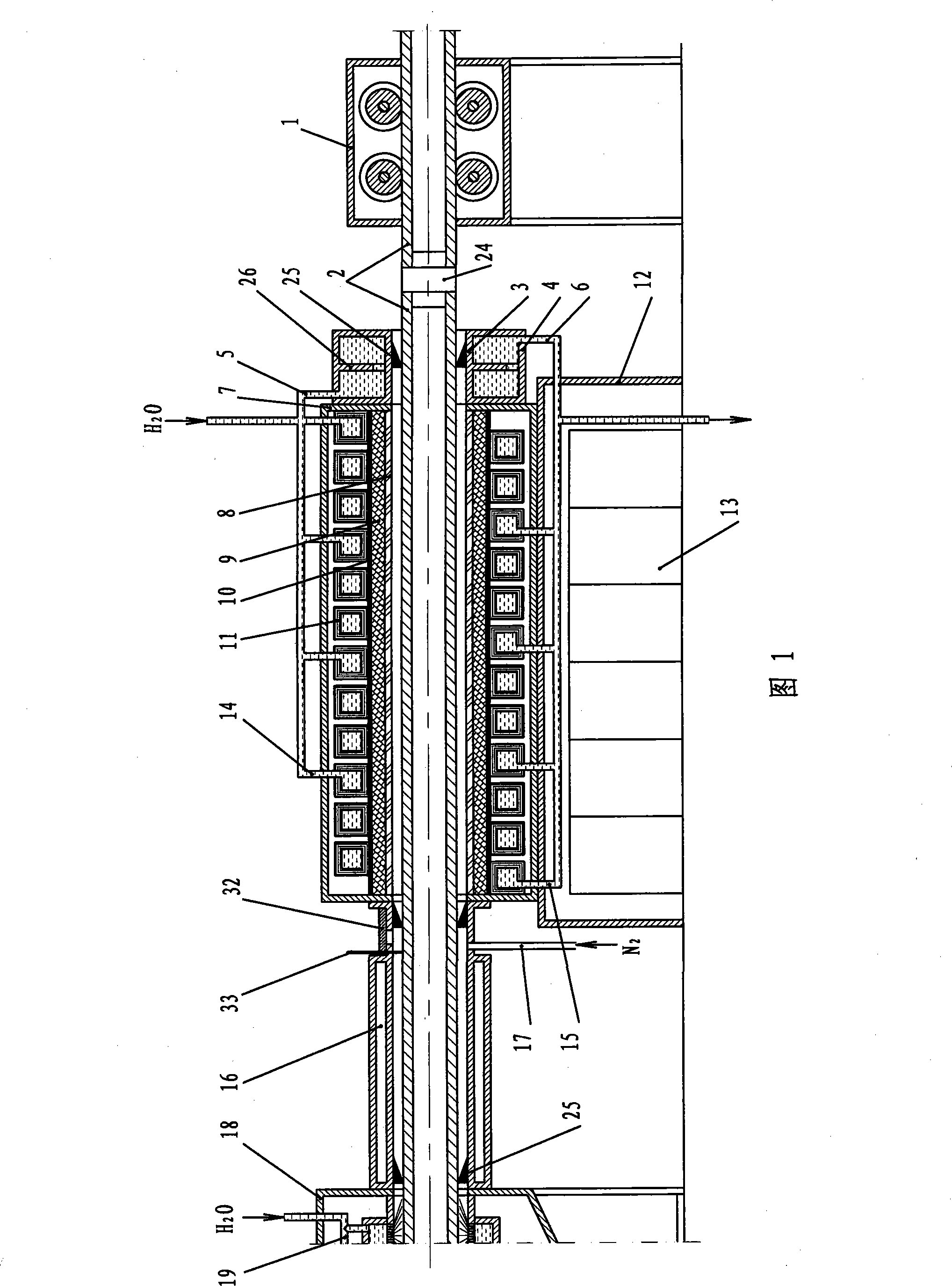

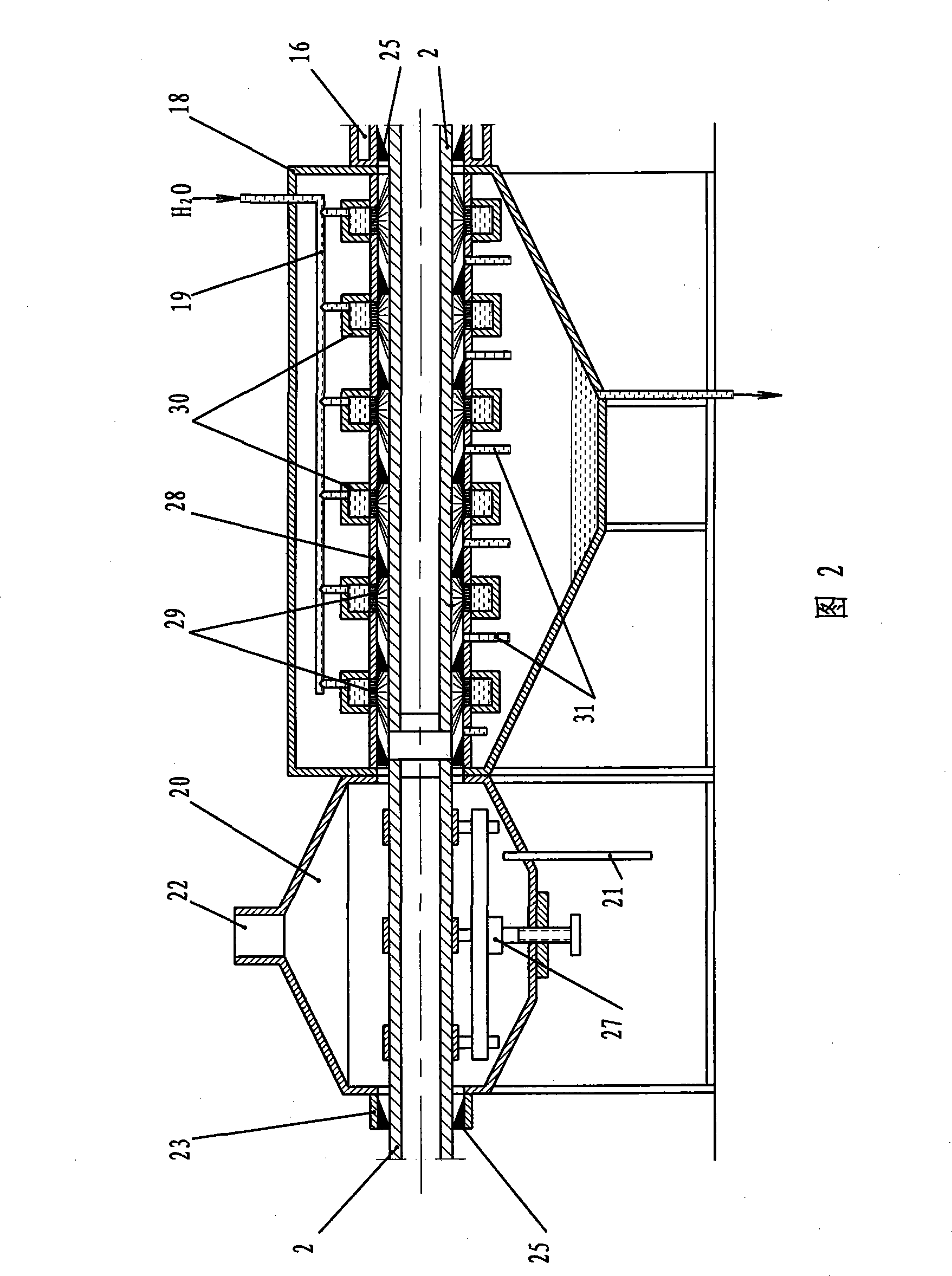

[0025] Figure 1 is a schematic cross-sectional view of the structure of the traction transition section, heating section and insulation section of the copper tube on-line annealing equipment of the present invention. Figure 2 is a schematic cross-sectional view of the cooling section and the air-drying section. Figures 1 and 2 are combined to form a complete set of equipment of the present invention. It can be seen from Figures 1 and 2 that the equipment used in the online annealing method for rolled copper pipes of the present invention includes a tractor 1 and successively connected transition sections, heating sections, heat preservation sections, cooling sections and air drying sections; For the length of tube 2, first insert a number of sponge plungers dipped in detergent into the tube, and blow the sponge column from one end to the other with a high-pressure air stream to clean the inner wall of the tube. At the same time, clean the tube with cotton yarn dipped in detergent....

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com