Preparation of high-potential gradient ZnO thick film piezoresistor

A varistor, high-potential technology, applied in varistor, varistor core, resistor manufacturing, etc., can solve the problems of high sintering temperature and low product potential gradient index, and achieve low sintering temperature and equipment requirements The effect of low cost and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

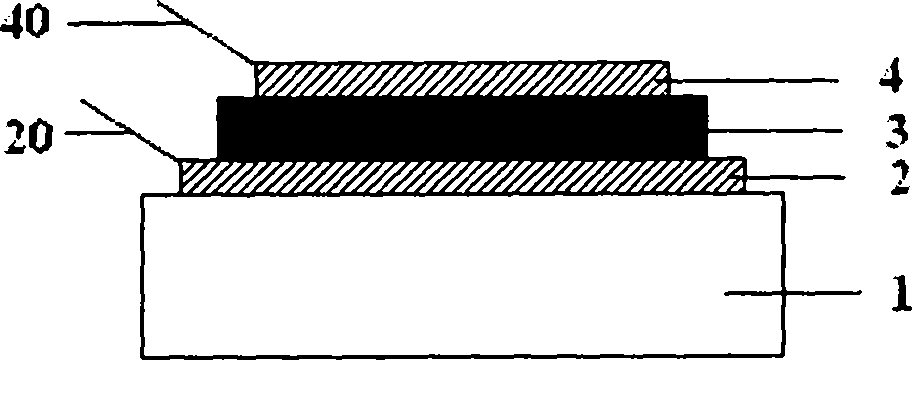

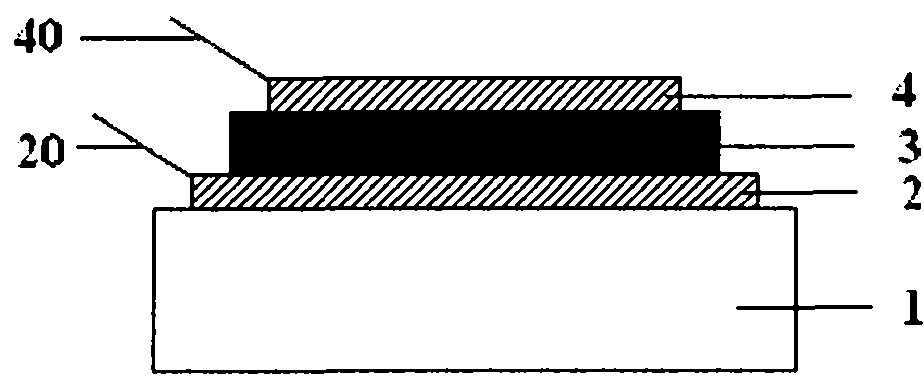

Method used

Image

Examples

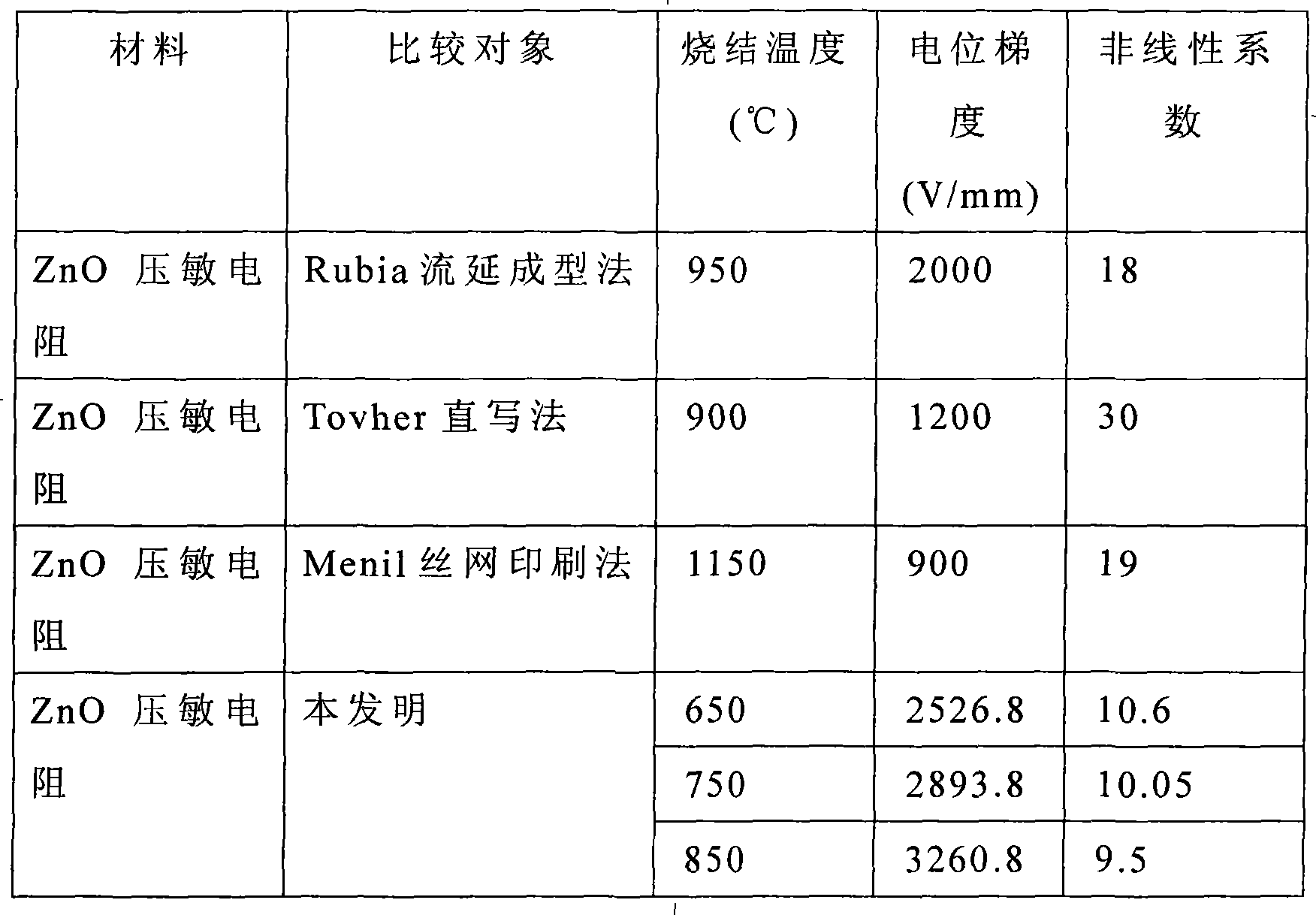

Embodiment 1

[0038] In the first step, ZnO:Bi 2 o 3 :Sb 2 o 3 :Cr 2 o 3 :Co 2 o 3 :MnO 2 : Y 2 o 3 The mol ratio is 96.48: 0.7: 1.0: 0.5: 0.8: 0.5: 0.02, X=0.02, wet milling in absolute ethanol for 10 hours, the ball-to-material ratio is 10:1, the ball milling speed is 300rpm, the dry mixed powder Put the powder into a ball mill tank, dry mill for 1 hour, the ball-to-material ratio is 10:1, and the ball milling speed is 300rpm; in the second step, the concentration of the organic carrier is 2%, and the mass ratio of the mixed powder to the organic carrier is 1:0.5 ; In the fourth step, the number of steps is 10, and each step is 2 times; in the sixth step, the temperature is slowly raised to 650°C and kept for 2 hours.

[0039] The electrical performance index of the product in this embodiment is: potential gradient 2526.8V / mm; nonlinear coefficient 10.6; leakage current 44.1μA.

Embodiment 2

[0041] In the first step, the molar ratio of ZnO: Bi2O3: Sb2O3: Cr2O3: Co2O3: MnO2: Y2O3 is 96.44: 0.7: 1.0: 0.5: 0.8: 0.5: 0.10, X=0.06, wet milling in absolute ethanol for 7.5 hours, The ball-to-material ratio is 25:1, the ball milling speed is 450rpm, put the dried mixed powder into a ball milling jar, dry mill for 1.5 hours, the ball-to-material ratio is 25:1, and the ball milling speed is 450rpm; in the second step, the The concentration is 6%, and the mass ratio of the mixed powder to the organic carrier is 1:2; in the fourth step, the number of steps is 5 steps, and each step is 3 times; in the sixth step, the temperature is slowly raised to 750°C and kept for 1.25 hours.

[0042] The electrical performance index of the product in this embodiment is: potential gradient 2893.8V / mm; nonlinear coefficient 10.05; leakage current 61.15μA.

Embodiment 3

[0044] In the first step, ZnO:Bi 2 o 3 :Sb 2 o 3 :Cr 2 o 3 :Co 2 o 3 :MnO 2 : Y 2 o 3 The mol ratio is 96.40: 0.7: 1.0: 0.5: 0.8: 0.5: 0.10, X=0.10, wet milling in absolute ethanol for 5 hours, the ball-to-material ratio is 40:1, the ball milling speed is 600rpm, the dried mixed powder The body was put into a ball mill tank, and dry milled for 2 hours, the ball-to-material ratio was 40:1, and the ball milling speed was 600rpm; in the second step, the concentration of the organic carrier was 10%, and the mass ratio of the mixed powder to the organic carrier was 1:1 ; In the fourth step, the number of steps is 2 steps, 5 times in each step; in the sixth step, the temperature is slowly raised to 850° C. and kept for 0.5 hours.

[0045] The electrical performance index of the product in this embodiment is: potential gradient 3260.8V / mm; nonlinear coefficient 9.5; leakage current 72.8μA.

[0046] The invention is particularly suitable for preparing high potential gradien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com