Method for eliminating chloro-aromatics low temperature catalytic combustion

A technology of chlorinated aromatic hydrocarbons and low-temperature catalysis, which is applied in the direction of combustion methods, combustion types, incinerators, etc., can solve the problems of easy loss of catalyst active components, low catalytic combustion activity, short catalyst life, etc., and achieve a convenient and practical technical route , High catalytic activity, strong anti-chlorine poisoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Commercially available 25g cerium nitrate (Ce(NO 3 ) 3 )·6H 2 O and 60g copper nitrate Cu(NO 3 ) 2 )·3H 2 O was dissolved in 80mL of ionized water, and the solution was placed in a constant temperature water bath at 50°C and stirred for 0.5h; then 70g of γ-Al was added to the solution 2 o 3 (with a surface area of 212m 2 / g), stirring continuously, until the impregnating solution is covered with γ-Al 2 o 3 After fully absorbed, stand still and age for 12 hours, then dry in an oven at 100°C for 24 hours, move to a roaster, program temperature rise in air atmosphere, 1°C per minute, rise to 180°C, keep for 2 hours; then program temperature increase, every minute 10°C, raise the temperature to 550°C, and keep it for 4 hours, you can get 20%CuO-10%CeO 2 / γ-Al 2 o 3 (by weight CuO:CeO 2 2:1) catalyst.

[0026] Prepare 22% Fe by implementing the method of 1 2 o 3 -8%CeO 2 / γ-Al 2 o 3 (by weight Fe 2 o 3 : CeO 2 is 22:8) the catalyst is Example 2.

[00...

Embodiment 4

[0029] Commercially available 5.3g lanthanum nitrate (La(NO 3 ) 3 )·6H 2 O and copper nitrate 32g Cu(NO 3 ) 2 )·3H 2 O was dissolved in 80mL of ionized water, and the solution was placed in a constant temperature water bath at 50°C and stirred for 0.5h; then 86g of SiO was added to the solution 2 (with a surface area of 312m 2 / g), stirring continuously during the process, until the impregnating solution is covered by SiO 2 After all absorption, stand still and age for 12 hours, then dry in an oven at 100°C for 24 hours, move to a roasting furnace, and roast in an air atmosphere. The method is as shown in Example 1, and 10% CuO-4% La can be obtained 2 o 3 / SiO 2 (by weight CuO:La 2 o 3 5:2) catalyst.

[0030] Prepare 20%NiO-4%La by implementing the method of 4 2 o 3 / SiO 2 (by weight NiO:La 2 o 3 is 5:1) the catalyst is Example 5.

[0031] Prepare 20% Co with the method of implementing 4 2 o 3 -4% La 2 o 3 / SiO 2 (by weight Co 2 o 3 : La 2 o 3 is 5:...

Embodiment 7

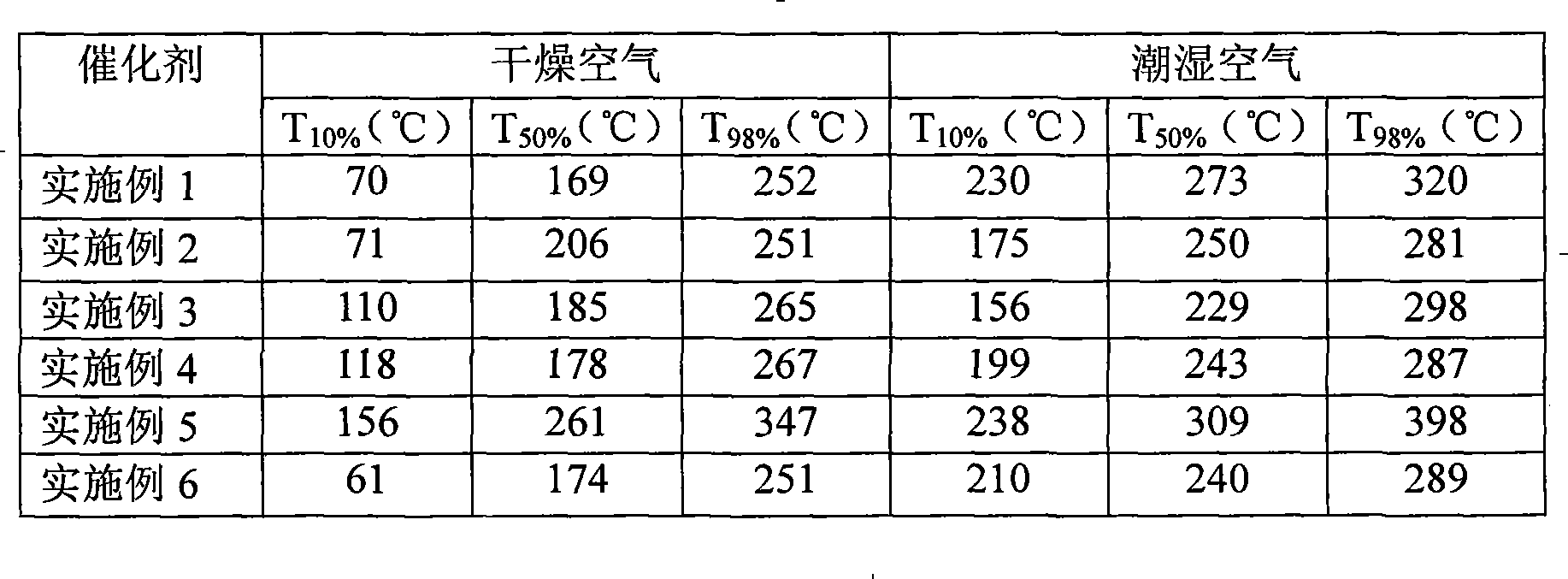

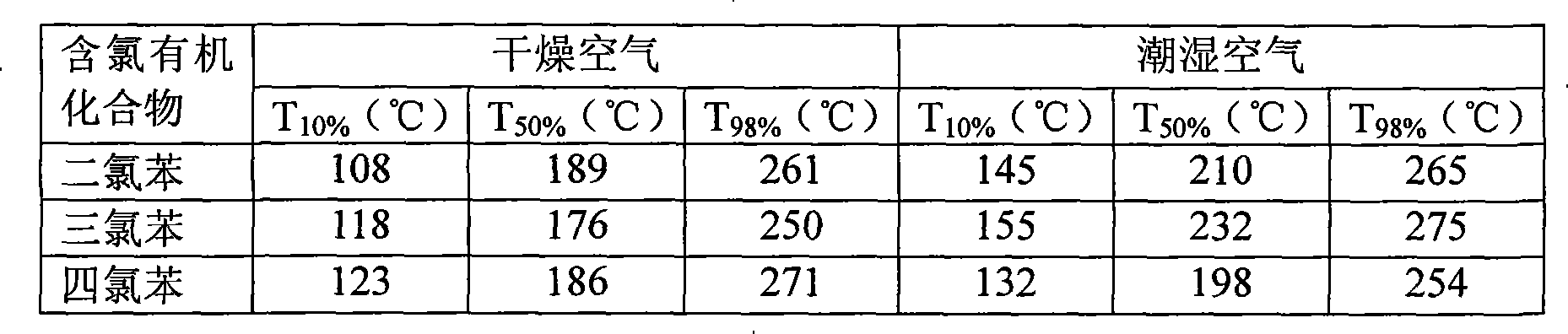

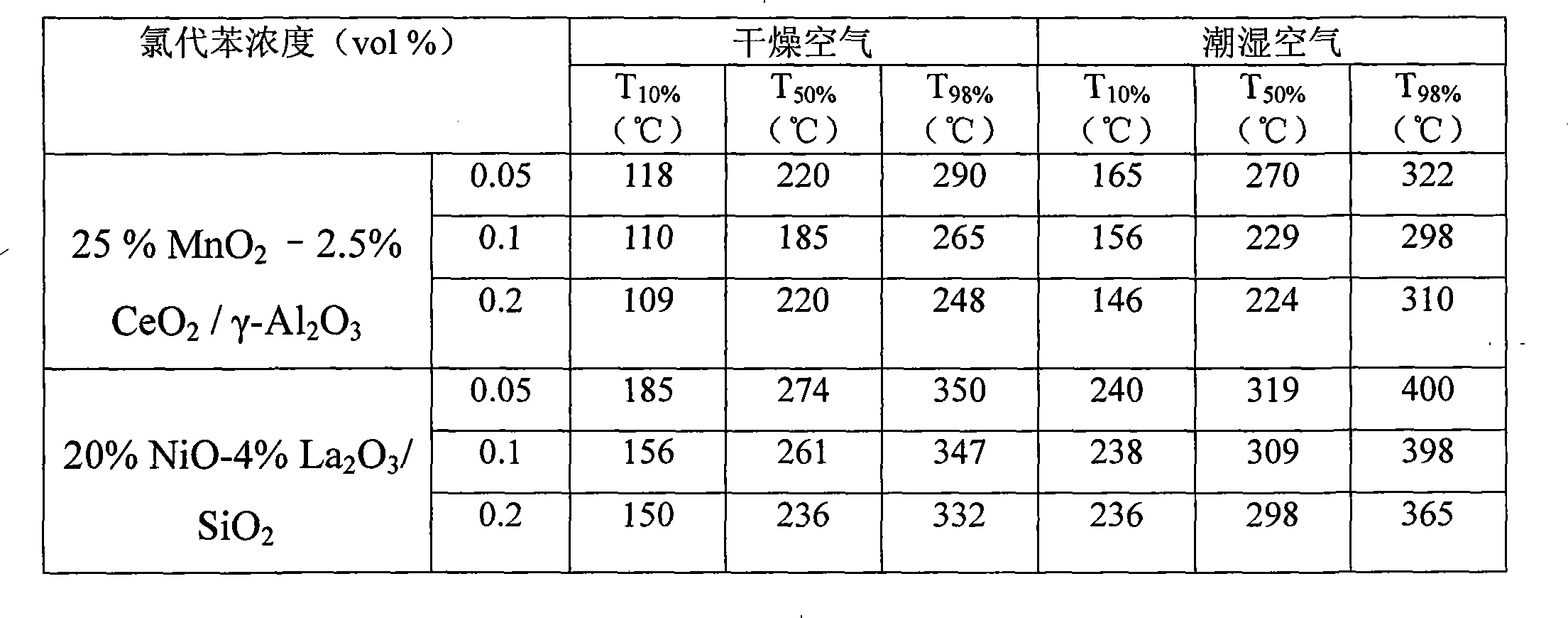

[0033] The evaluation of the combustion activity of all catalysts for chlorobenzene was carried out in a fixed-bed micro-reactor (quartz with an inner diameter of 6 mm), the amount of catalyst used was 200 mg, and the temperature was automatically controlled by a K-type thermocouple. Chlorobenzene is injected into the vaporization chamber by the 100 series KDS120 micro-injection pump of Stoelting Company in the United States, and then mixed with dry air and moist air with a water concentration of 5vol% respectively into the reactor for combustion. The total flow is controlled by a mass flow meter, the concentration of chlorobenzene is controlled at 0.1vol%, the amount of exhaust gas treated per gram of catalyst per hour is 15L, and the linear velocity of gas passing through the reactor is 120m / h. Reaction pressure is 0.1Mpa, and the relation of the conversion ratio of chlorobenzene and temperature of reaction is shown in Table 1, and T in the table 10% , T 50% , T 98% are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com