Heavy corrosion protection coating for ocean steel construction

A steel structure, heavy-duty anti-corrosion technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of inability to repaint, poor adhesion, and poor wettability of coatings to substrates, and achieve excellent film performance, The effect of excellent corrosion resistance, excellent adhesion and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A, B, C component composition, by mass percentage:

[0028] Component A: modified epoxy resin 80, plasticizer 15, leveling agent 0.1, defoamer 0.3;

[0029] Component B: Epoxy curing agent T31 curing agent (Mannich base curing agent)

[0030] Component C: wear-resistant pigment 90, alkaline water-absorbing agent 50, anti-rust pigment 3, anti-cracking pigment 8

Embodiment 2

[0032] A, B, C component composition, by mass percentage:

[0033] Component A: modified epoxy resin 60, plasticizer 10, leveling agent 0.2, defoamer 0.2;

[0034] B component: epoxy curing agent

[0035] Component C: wear-resistant pigment 60, alkaline water-absorbing agent 40, anti-rust pigment 5, anti-cracking pigment 6

Embodiment 3

[0037] A, B, C component composition, by mass percentage:

[0038] Component A: modified epoxy resin 90, plasticizer 18, leveling agent 0.3, defoamer 0.5;

[0039] B component: epoxy curing agent

[0040] Component C: wear-resistant pigment 75, alkaline water-absorbing agent 30, anti-rust pigment 8, anti-cracking pigment 5

[0041] According to the proportion of raw materials, three components A, B and C are prepared, and the components A, B and C are mixed according to the ratio of 100:20:200 to prepare a sample plate and measure the coating performance.

[0042] The method of use is to treat the base material with sandblasting or shot blasting to Sa2.5 level, mix A, B, and C components evenly in proportion, and apply it by scraping. The thickness of one layer can reach 500 microns.

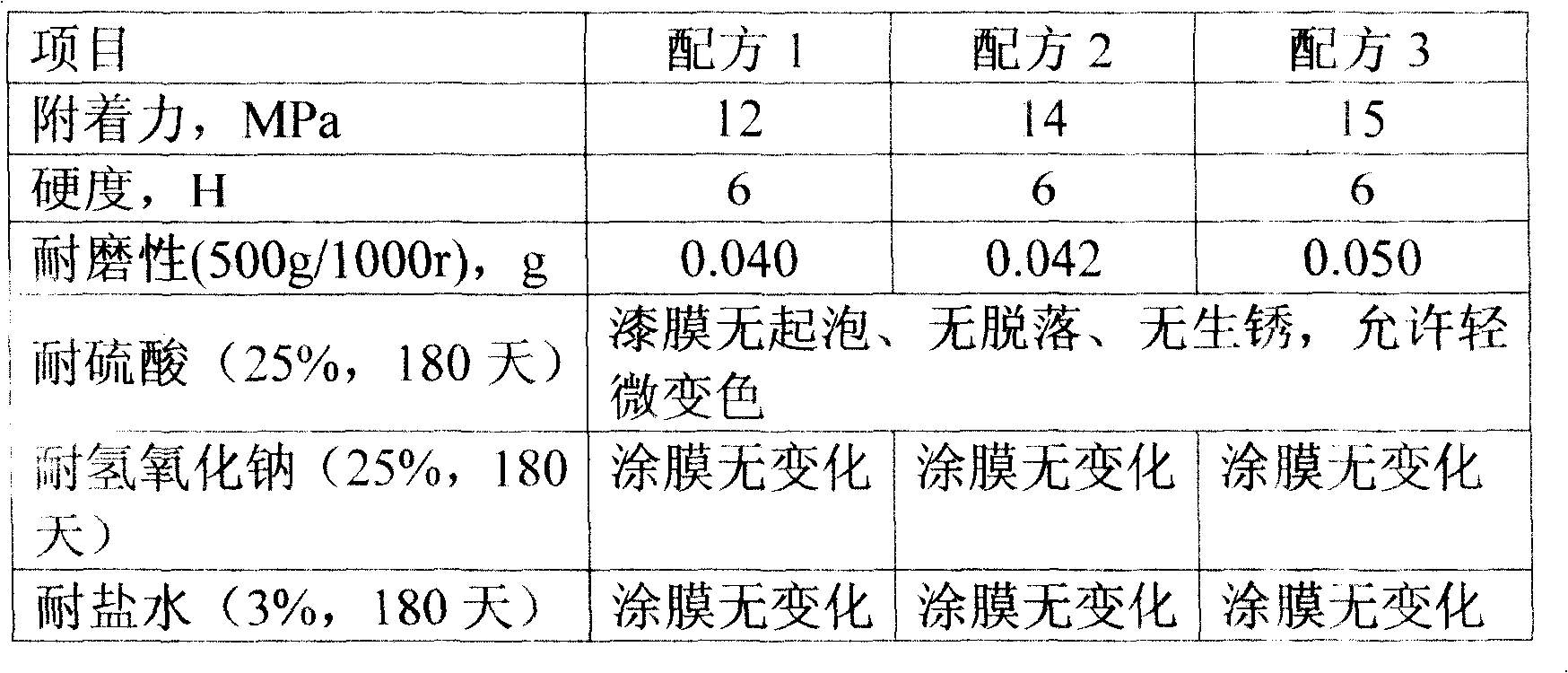

[0043] The heavy-duty anti-corrosion coating for marine steel structure produced by the above ratio has the following performance indicators:

[0044] Table 1 Performance Index

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com