Pigment -type photosensitive material

A technology of photosensitive materials and pigments, applied in optics, optical components, opto-mechanical equipment, etc., can solve the problems of lowering the thermal cracking temperature of carbon black, unsuitable color filter black matrix, poor heat resistance, etc. Heat resistance and dimensional stability, maintaining color stability, reducing the effect of thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

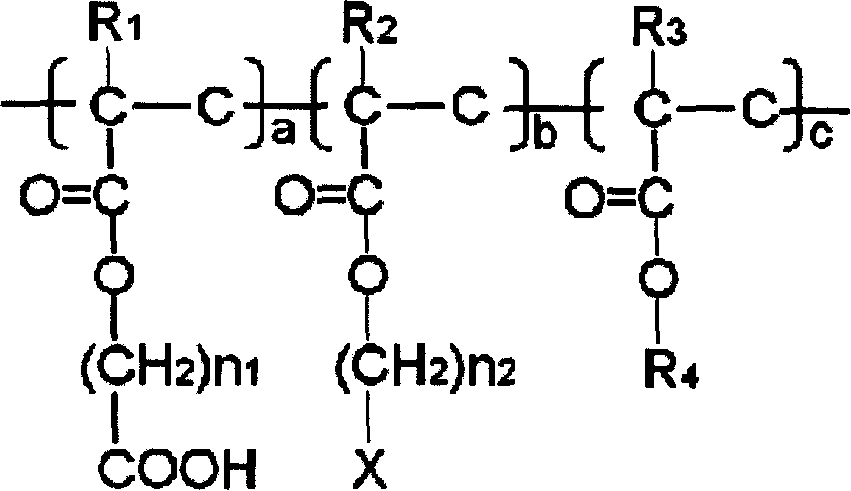

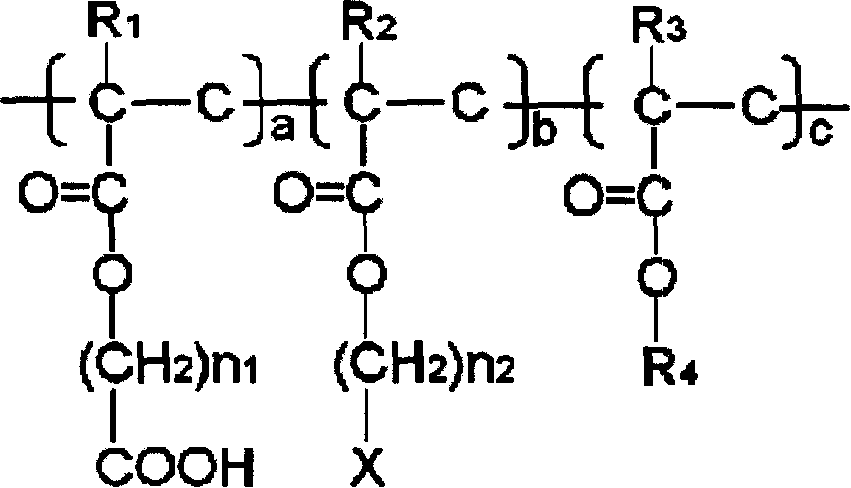

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the pigment-type photosensitive material of the present invention can first disperse the surface-modified pigment with a dispersant, then add alkali-soluble resin, multifunctional monomer, photoinitiator and solvent and mix evenly, and finally add other ingredients Add in, stir well at high speed before use.

[0032] The pigment-type photosensitive material of the present invention can be applied to a color filter as a material for a color photoresist and a black matrix, and the manufacturing steps include coating the color photoresist on a transparent glass substrate by spin coating on, pre-baked at 90°C for about 2 minutes; 2 The ultraviolet light source is exposed with a photomask with a specific pattern, and the exposed part produces a cross-linking reaction; then it is developed with an alkaline aqueous solution, the unexposed part is washed away by the alkali solution, and the pattern of the exposed part is retained; the pattern is washed...

preparation example 1

[0037] In a 250 ml grinding tank, add zirconium balls of 1 mm in diameter to 1 / 2 grinding tank volume, add 100 g of tetrahydrofuran (THF) solvent, then add 40 g of red pigment (pigment red 254, referred to as PR254, purchased from Ciba) and 5 g of inorganic alkanes Oxygen compound modifier 3-aminopropyltriethoxysilane (3-Aminopropyltriethoxysilane), disperse this mixed solution with a red devil grinder for 2 hours, take it out and place it in a 250g round bottom reaction bottle, and then add 1.7g pH The hydrochloric acid aqueous solution of 2.1 is continuously stirred; Then, add 5g inorganic alkoxy compound modifier triethoxymethyl silane (Triethoxymethyl silane, TEOS), this 5g TEOS carries out hydrolysis reaction in hydrochloric acid aqueous solution, stirs at room temperature 24 Hours and after THF volatilized, it was aged at high temperature (110° C.) for 8 hours to complete the condensation reaction, that is, the preparation of the red pigment coated with inorganic alkoxy c...

preparation example 2

[0039] Add 100g THF solvent in the grinding pot of 250 milliliters, then add 40g red pigment (pigment red 254, purchased from Ciba), this mixed solution is dispersed 2 hours with red devil grinder, takes out and is placed in 250g round bottom reaction bottle, Then add 1.7g of hydrochloric acid aqueous solution with a pH value of 2.1 and continue to stir; then, add 5.65g of TEOS, the TEOS is hydrolyzed in aqueous hydrochloric acid, stirred at room temperature for 24 hours and after THF volatilizes, mature at high temperature (110°C) After 8 hours, the condensation reaction is complete, that is, the preparation of the red pigment coated with the inorganic alkoxy condensate is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com