Crack arrest method of alloy surface fine crack crack arrest method and device thereof

A micro-crack and alloy technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve problems such as application limitations and difficult operation, achieve fatigue limit stress enhancement, realize recycling, and increase fatigue threshold Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

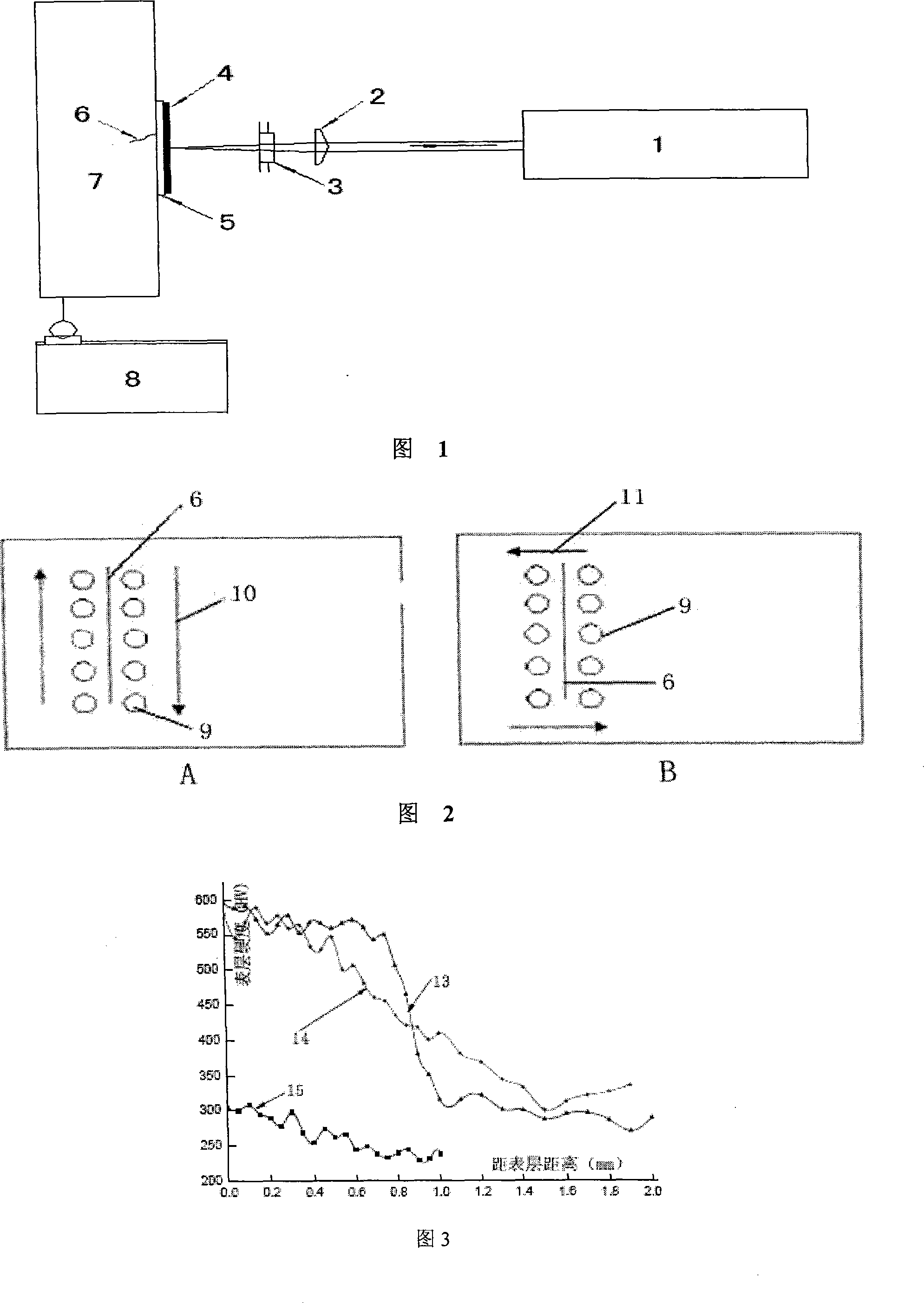

Embodiment 1

[0033] Before the repaired aluminum alloy 2024 sample is cracked by laser, the oxide layer and pollutants on the surface of the alloy crack that affect the bonding force are removed by mechanical methods such as surface polishing, so as to increase the mechanical bonding surface and obtain higher bonding strength and durability. sex. Then apply a layer of glass film on the surface of the alloy as a crack stop patch, and coat a layer of black paint on the glass film. According to the damaged length of the crack is 5mm, when surface cracks appear on the surface of the alloy plate shown in Figure 1 , the pulse energy is 30J, the pulse width is 20ns, the spot size is 6mm, and the laser parameters are selected as the repetition frequency 1Hz for laser shock arrest. Figure 1 shows the schematic diagram of laser shock arrest. The neodymium glass laser emits pulsed laser beams through the lens to arrest cracks through the lens window; choose the arrest route A and the arrest route B (...

Embodiment 2

[0035] The sample is a TC4 alloy blade with a surface crack length of 1.7 mm. The surface is pretreated first, and then coated with glass film, and the surface of the TC4 alloy blade is subjected to laser shock arrest. The pulse energy is 20J, the pulse width is 22.5ns, and the repetition frequency is 0.5Hz for laser shock arrest.

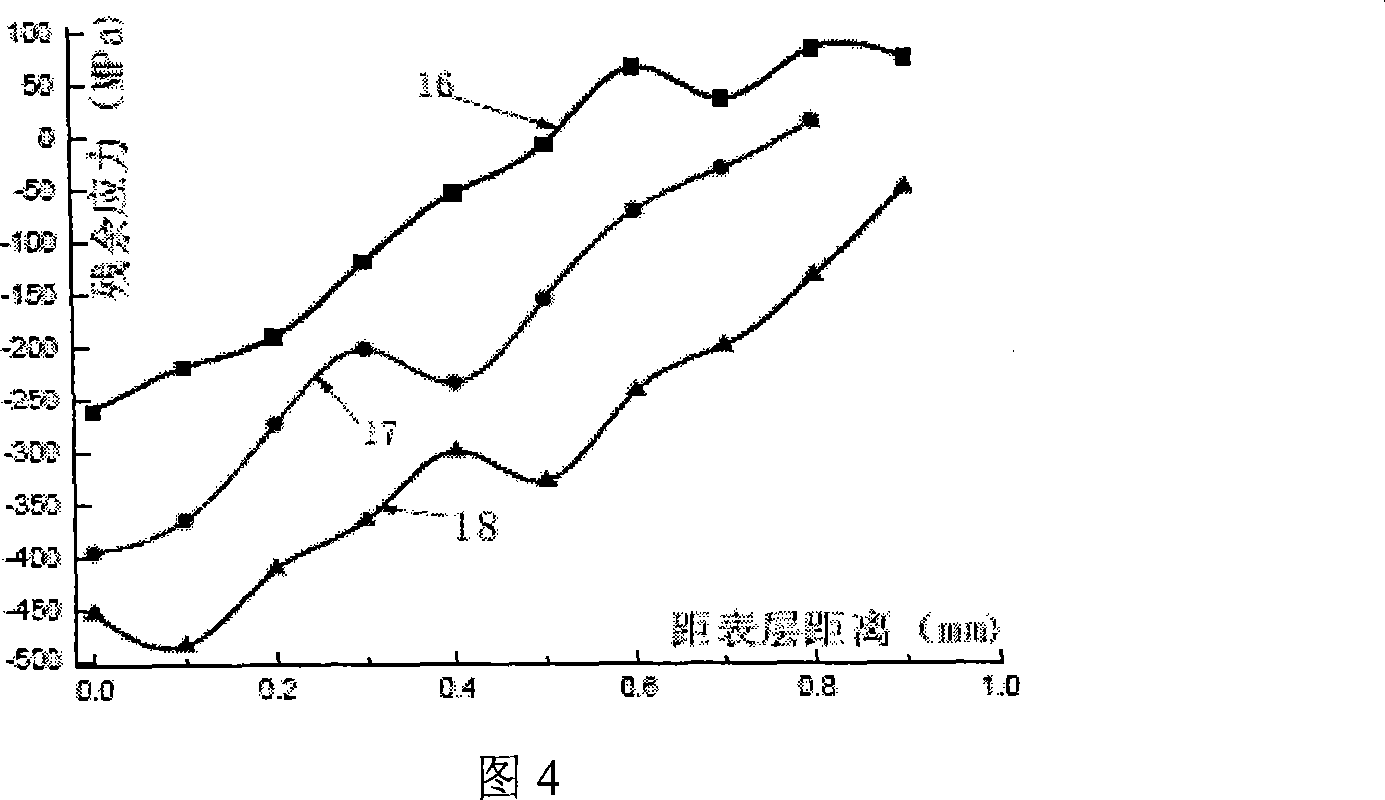

[0036] After the surface of the TC4 alloy blade is subjected to the laser shock arrest test, the residual stress of the surface crack is measured by the X-350A X-ray stress analyzer of Hebei Est Stress Technology Co., Ltd. The distribution of the residual stress is shown in Figure 4 . It can be seen from the figure that the residual stress of the blade surface is compressive stress. Moreover, the stress level is high, the stress distribution is obvious, and the change trend of the stress starts from the surface and decreases linearly with the increase of the surface distance. Compared with the laser cladding repair treatment, the residual compress...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com