Screen printing carbon electrode pretreatment method

A technology of screen printing and carbon electrodes, which is applied in the direction of printing and printing devices, can solve the problems of polishing technology and polishing material requirements, unsatisfactory activation effect, easy to damage electrodes, etc., and achieve simple pretreatment methods and reversible electrodes The effect of enhancing sex and electron transfer rate and eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

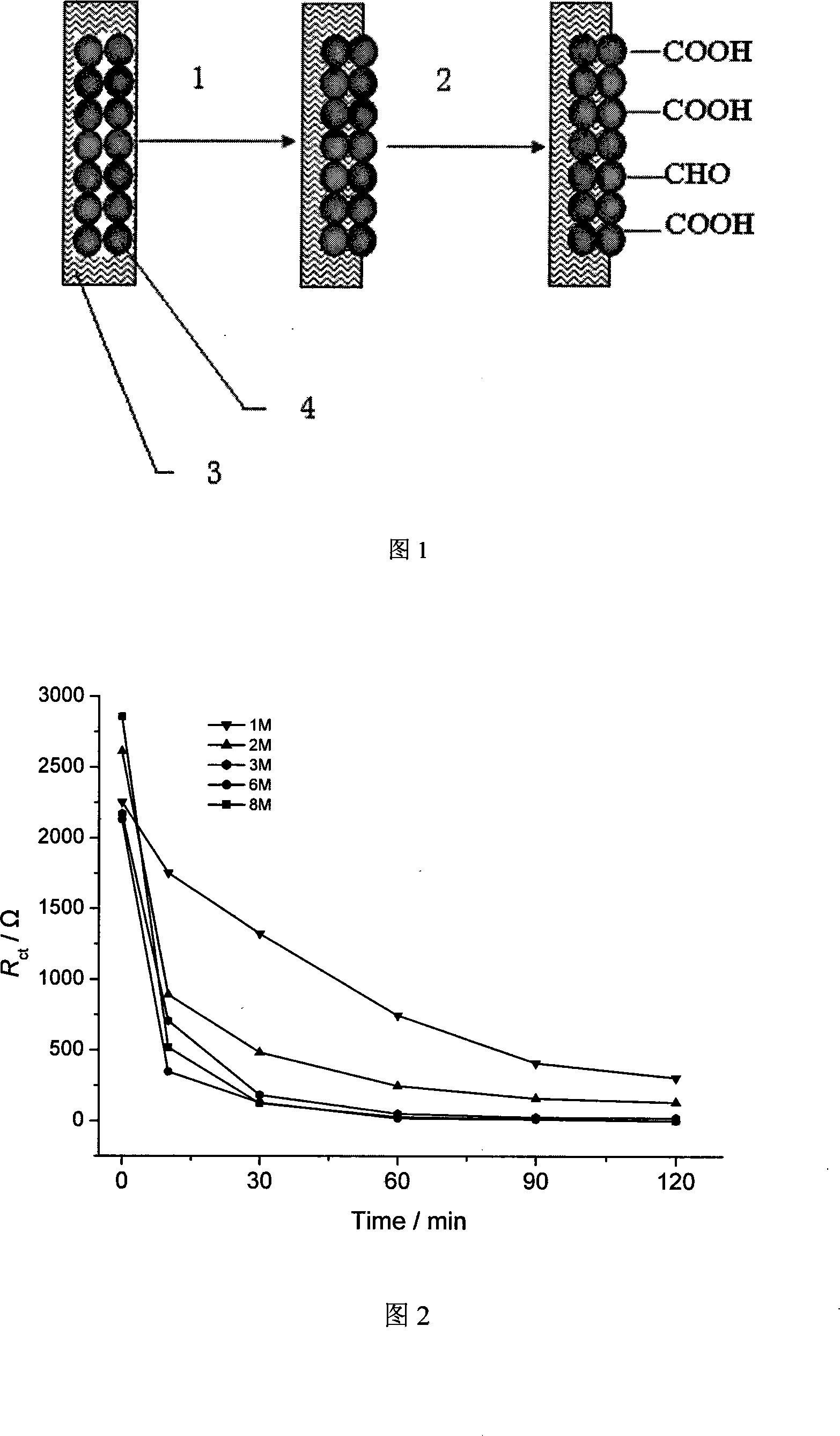

[0024]Soak five screen-printed carbon electrodes in NaOH solution with a concentration of 3mol / L for 0 minutes, 10 minutes, 30 minutes, 60 minutes, and 90 minutes, then take out the electrodes, rinse them with secondary water, and put The processed electrode was used as a working electrode, the reference electrode was a saturated calomel electrode (SCE), and the counter electrode was a platinum sheet electrode. In an electrochemical analyzer CHI832 (Shanghai Chenhua Instrument Co., Ltd.), cyclic voltammetry was used to investigate different treatment times. The response of the screen-printed carbon electrode to potassium ferricyanide is shown in Figure 3. It can be seen from the figure that with the increase of soaking time, the peak potential difference gradually decreases and the response current increases, indicating that The reversibility of the electrode becomes better, and the electron transfer rate is significantly enhanced.

Embodiment 2

[0026] Soak the prepared screen-printed carbon electrode in a NaOH solution with a concentration of 4mol / L for 20 minutes, and then soak the electrode in a NaOH solution with a concentration of 0.5mol / L in an electrochemical analyzer CHI832 (Shanghai Chenhua Instrument company) is activated by a constant potential method, the anode potential applied by the constant potential is set to +1.2V, and the activation time is 20 seconds. Prepare 1×10 -3 mol / L dopamine phosphate buffer solution (pH7.0), using untreated screen-printed carbon electrodes, electrodes soaked in strong alkali solution by chemical treatment, and electrodes treated by combined chemical and electrochemical treatment. The electrode is used as the working electrode, the reference electrode is a saturated calomel electrode (SCE), and the counter electrode is a platinum sheet electrode. In an electrochemical analyzer CHI832 (Shanghai Chenhua Instrument Co., Ltd.), the differential pulse voltammetry was used to inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com