Alloy for negative electrode of lithium secondary battery

A lithium secondary battery and alloy technology, applied in secondary batteries, lithium batteries, battery electrodes, etc., can solve the problems of increasing internal resistance and achieve the effects of large charge and discharge capacity and good charge and discharge cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

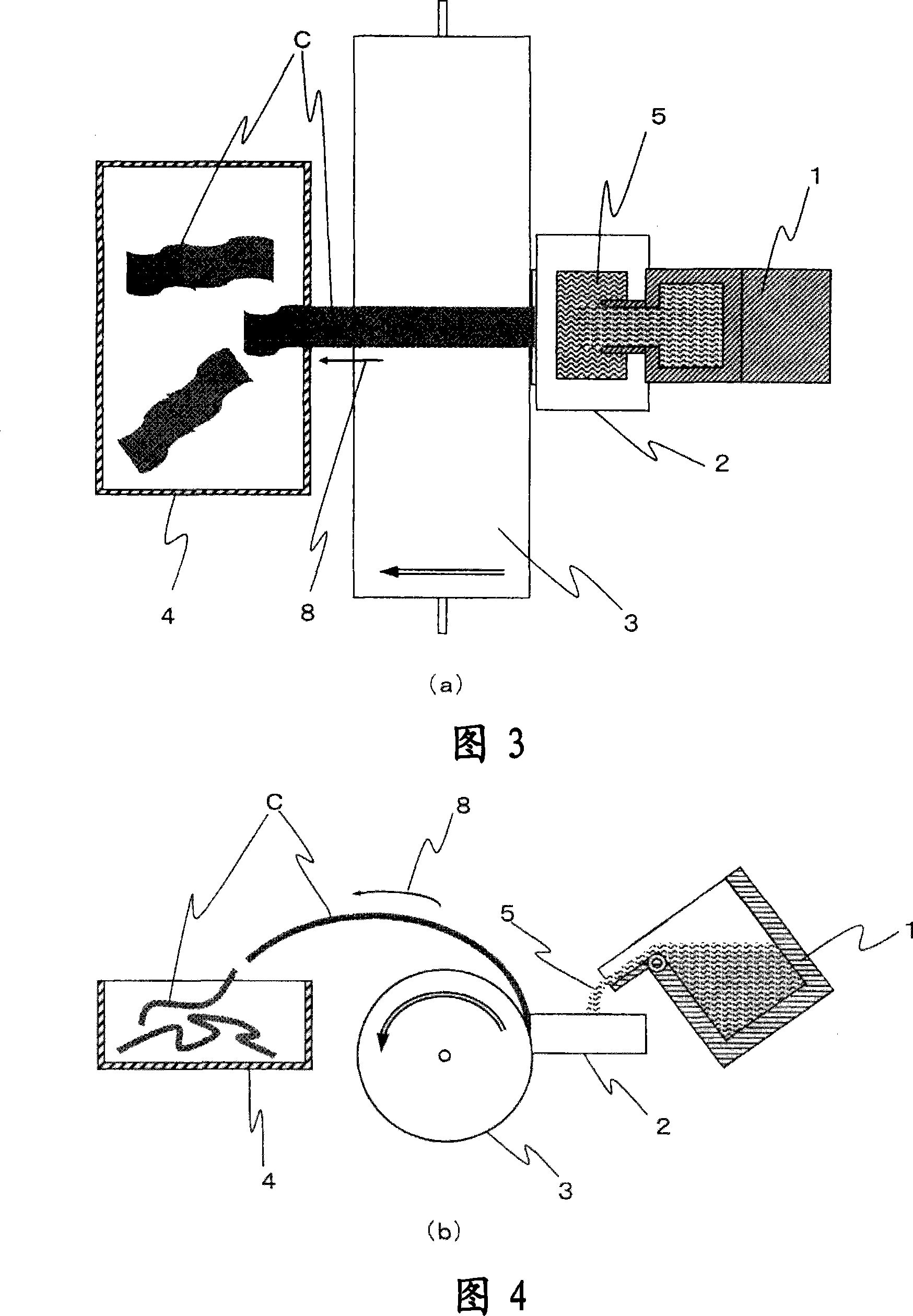

[0129] Into a crucible comprising a double-layer structure of carbon and alumina, 210 g of tin metal (2N {99% purity}), 455 g of silicon metal (4N {99.99% purity}) and 35 g of electrolytic copper were added, followed by It was heated at 1400° C. in the presence of argon in a frequency induction furnace to prepare a melt. With the equipment for the strip casting method comprising the units shown in FIGS. with cast alloy. A cooling roll made of copper was rotated at a peripheral speed of 1.0 m / sec, the thickness of the strip cast alloy was 300 μm, and the cooling rate from the melt temperature to 600° C. was 3000° C. / sec.

[0130] The resulting strip cast alloy was ground into a powder in an alumina mortar for analysis by X-ray diffraction. Diffraction peaks corresponding to Sn metal and Si metal were identified, respectively. A close-up cross section of the alloy with a scanning electron microscope (S-530 produced by Hitachi High-Technologies Co.) showed two phases, a phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com