Environment-friendly type transformer oil and preparation method thereof

A kind of transformer oil, environment-friendly technology, applied in the field of environment-friendly transformer oil and its preparation, can solve the problems of base oil biodegradation performance, rarely consider environmental protection and health, affect the base oil biodegradation rate and other problems, achieve good economical The effect of high efficiency, stable product quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

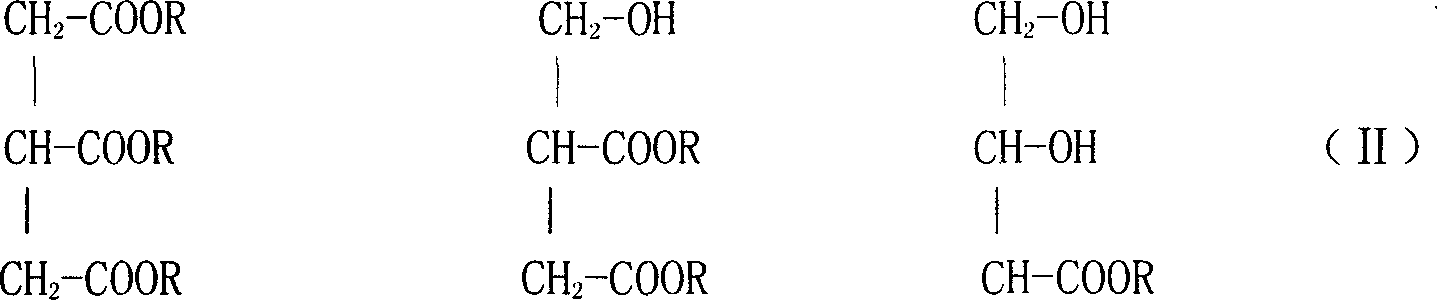

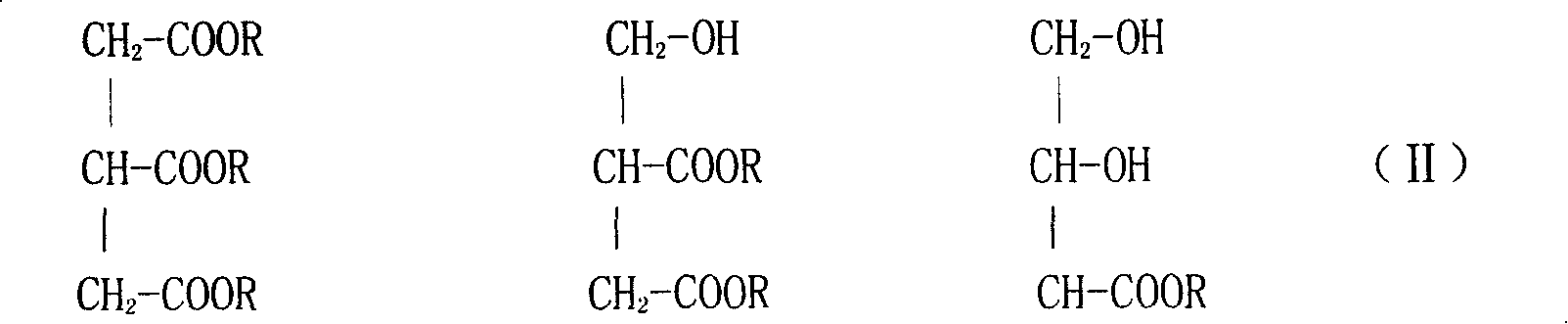

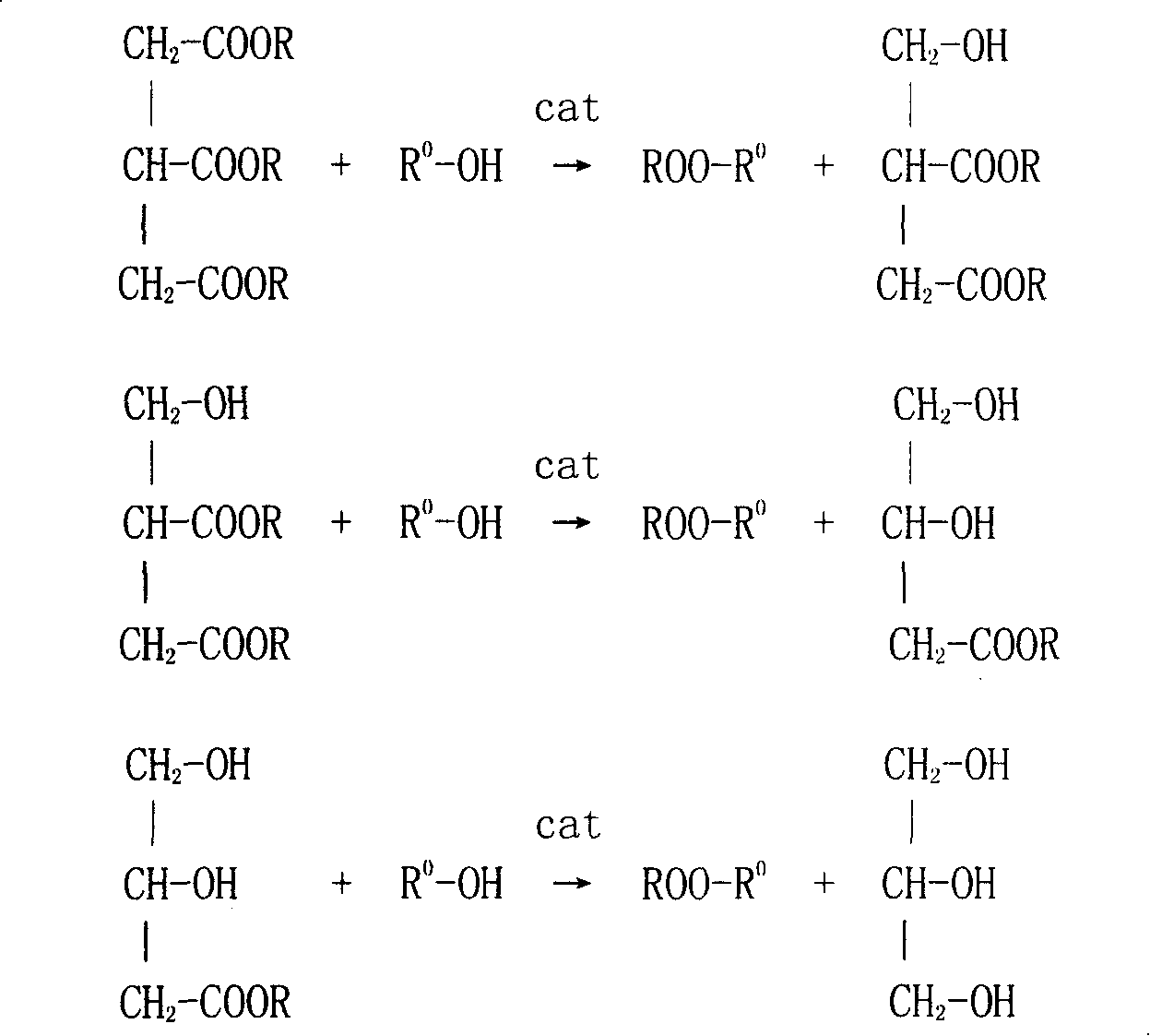

Method used

Image

Examples

example 1

[0028] Raw materials are vegetable oils including castor oil, coconut oil, cottonseed oil, palm oil, palm kernel oil, soybean oil, linseed oil, rapeseed oil, etc. pressed oil, extracted oil and leftovers from the oil processing industry (oil foot, soap foot) ) After alkali refining and dehydration treatment, the acid value is ≤0.002mgKOH / g, the water content is ≤0.01%, and the lower alcohols with 2 to 5 carbon atoms are put into the reaction kettle according to the following ratio, and reflux at a temperature of 60 to 150°C React for 1 to 8 hours, stop neutralization, wash and refine, and carry out vacuum distillation with a packed tower. During vacuum distillation, the absolute pressure is 0.5 to 4 mmHg, and the temperature is 150 ° C. The by-product glycerin is separated, and the excess low-carbon alcohol is recovered for reuse. Remove water and low-molecular volatiles, and finally use activated clay, anhydrous calcium chloride, molecular sieve, and activated carbon compound ...

example 2

[0034]Raw materials are vegetable oils including castor oil, coconut oil, cottonseed oil, palm oil, palm kernel oil, soybean oil, linseed oil, rapeseed oil, etc. pressed oil, extracted oil and leftovers from the oil processing industry (oil foot, soap foot) ) After alkali refining and dehydration treatment, the acid value is ≤0.002mgKOH / g, the water content is ≤0.01%, and the lower alcohols with 2 to 5 carbon atoms are put into the reaction kettle according to the following ratio, and reflux at a temperature of 60 to 150°C React for 1 to 8 hours, stop neutralization, wash and refine, and carry out vacuum distillation with a packed tower. During vacuum distillation, the absolute pressure is 0.5 to 4 mmHg, and the temperature is 150 ° C. The by-product glycerin is separated, and the excess low-carbon alcohol is recovered for reuse. Remove water and low-molecular volatiles, and finally use activated clay, anhydrous calcium chloride, molecular sieve, and activated carbon compound d...

example 3

[0040] Raw materials are vegetable oils including castor oil, coconut oil, cottonseed oil, palm oil, palm kernel oil, soybean oil, linseed oil, rapeseed oil, etc. pressed oil, extracted oil and leftovers from the oil processing industry (oil foot, soap foot) ) After alkali refining and dehydration treatment, the acid value is ≤0.002mgKOH / g, the water content is ≤0.01%, and the lower alcohols with 2 to 5 carbon atoms are put into the reaction kettle according to the following ratio, and reflux at a temperature of 60 to 150°C React for 1 to 8 hours, stop neutralization, wash and refine, and carry out vacuum distillation with a packed tower. During vacuum distillation, the absolute pressure is 0.5 to 4 mmHg, and the temperature is 150 ° C. The by-product glycerin is separated, and the excess low-carbon alcohol is recovered for reuse. Remove water and low-molecular volatiles, and finally use activated clay, anhydrous calcium chloride, molecular sieve, and activated carbon compound ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com