Preparing method of compound collagen hemostatic material

A technology of hemostatic material and composite glue, applied in bandages, absorbent pads, medical science, etc., can solve the problems of short hemostatic time, high price, easy to fall off, etc., and achieve the effect of expanding market share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

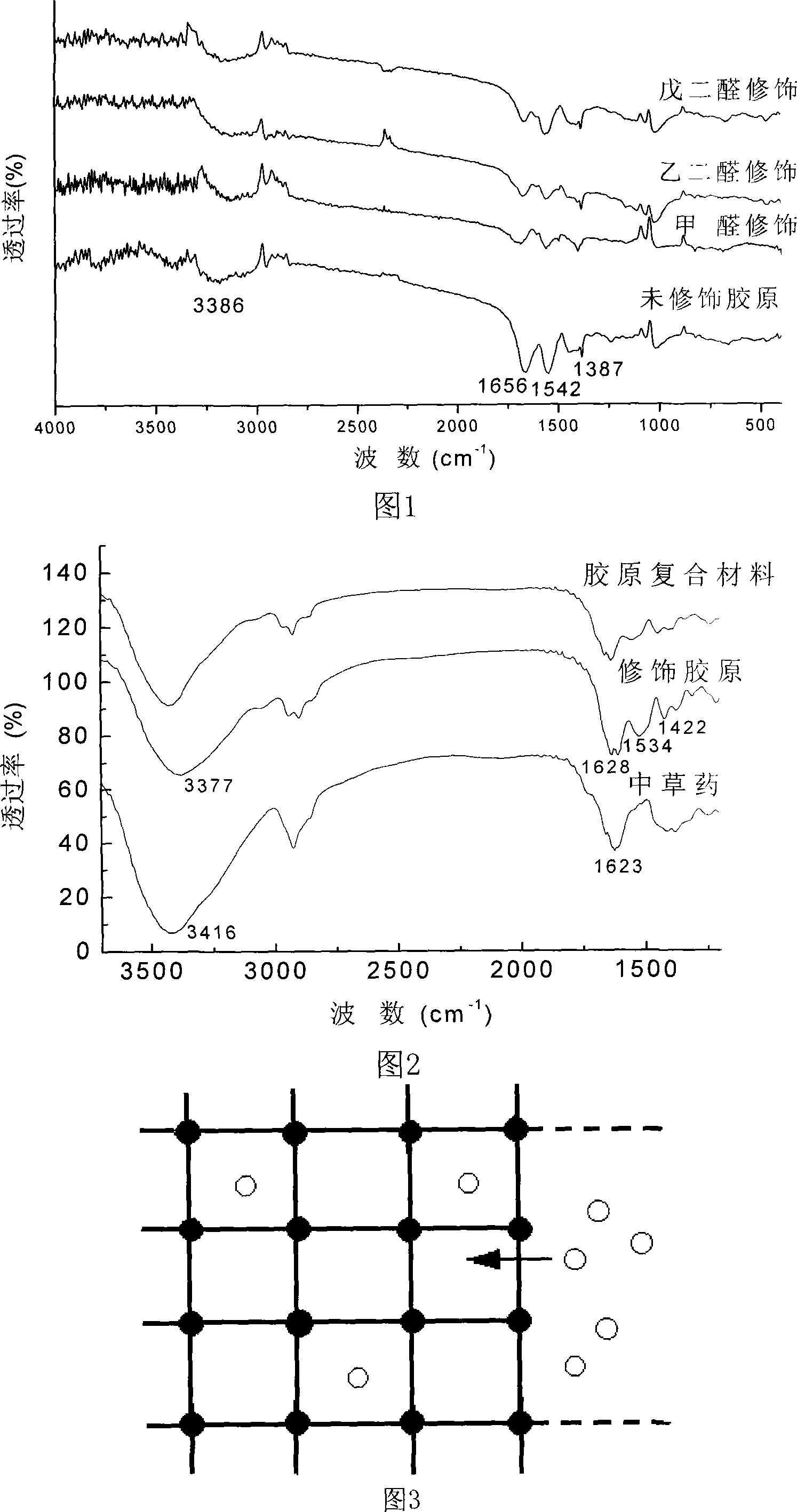

[0027] Example 1: Glutaraldehyde modified collagen with Chinese herbal medicine

[0028] Step 1) preparation of collagen cotton net:

[0029] Cow split hide is made into gray hide, weighed 10g, and broken. Add liming agent Ca(OH) with a concentration of 2% by mass 2 , water 100ml, liming, after reacting at room temperature for 24 hours, fully washed with water, and then using 4% deliming agent NH 4 Cl, water 50ml, carry out deliming, react at room temperature for 6h; fully wash; mince; hydrolyze with pepsin at a mass percent concentration of 3‰ for 48h, centrifuge at a speed of 10000rpm; adjust the pH value to 7 with NaOH, using mass percent Salt out with 4% NaCl, let it stand for 24 hours; centrifuge twice at 10,000 rpm; use 200 ml of 0.5 mol / L acetic acid for acid dissolution, and freeze-dry to make collagen cotton mesh.

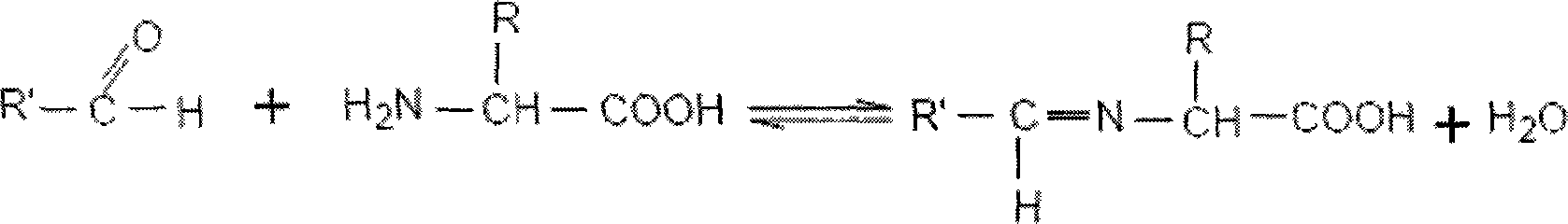

[0030] Step 2) Collagen modification:

[0031] Prepare a glutaraldehyde solution with a mass percentage concentration of 2%, adjust the pH value of th...

example 2

[0038] Example 2: Glutaraldehyde modified collagen with Chinese herbal medicine

[0039] Step 1) preparation of collagen cotton net:

[0040] Cow split hide is made into gray hide, weighed 10g, and broken. Add liming agent Ca(OH) with a concentration of 3% by mass 2 , water 100ml, liming, after reacting at room temperature for 36h, fully washing with water, and then using deliming agent NH with a concentration of 6% by mass 4 Cl, 50ml of water, deashed, reacted at room temperature for 6h; fully washed with water; minced; hydrolyzed with pepsin at a mass percent concentration of 3‰ for 60h, centrifuged at a speed of 15000rpm; adjusted the pH value to 7 with NaOH, using mass percent The concentration is 4% NaCl salting out, let it stand for 24 hours; second centrifugation, the rotation speed is 15000 rpm; 200ml of 0.5mol / L acetic acid is used for acid dissolution, freeze-dried to make collagen cotton mesh.

[0041] Step 2) Collagen modification:

[0042] Prepare a glutaralde...

example 3

[0046] Example 3: Glyoxal modified collagen with Chinese herbal medicine

[0047] Step 1) preparation of collagen cotton net:

[0048] Cow split hide is made into gray hide, weighed 10g, and broken. Add liming agent Ca(OH) with a concentration of 3% by mass 2 , water 100ml, liming, after reacting at room temperature for 48h, fully washing with water, and then using a deliming agent (NH 4 ) 2 SO 4 , water 50ml, carry out deliming, react at room temperature for 10h; fully wash; mince; hydrolyze with pepsin at a mass percent concentration of 3‰ for 72h, centrifuge at a speed of 20,000rpm; adjust the pH value to 7 with NaOH, using a mass percent concentration of Salt out with 4% NaCl, let it stand for 24 hours; centrifuge twice at 20,000 rpm; use 200 ml of 0.5 mol / L acetic acid for acid dissolution, freeze-dry to make collagen cotton mesh.

[0049] Step 2) Collagen modification:

[0050] Prepare a glyoxal solution with a mass percentage concentration of 3%, adjust the pH val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com