Method for detecting releasing degree of semiconductor chip from electrostatic chuck

An electrostatic chuck, semiconductor technology, used in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, circuits, etc., can solve problems such as damage to the thimble and manipulator, wafer bounce or displacement, and lack of access to reduce accidents. Incidence, avoidance of jumping or shifting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

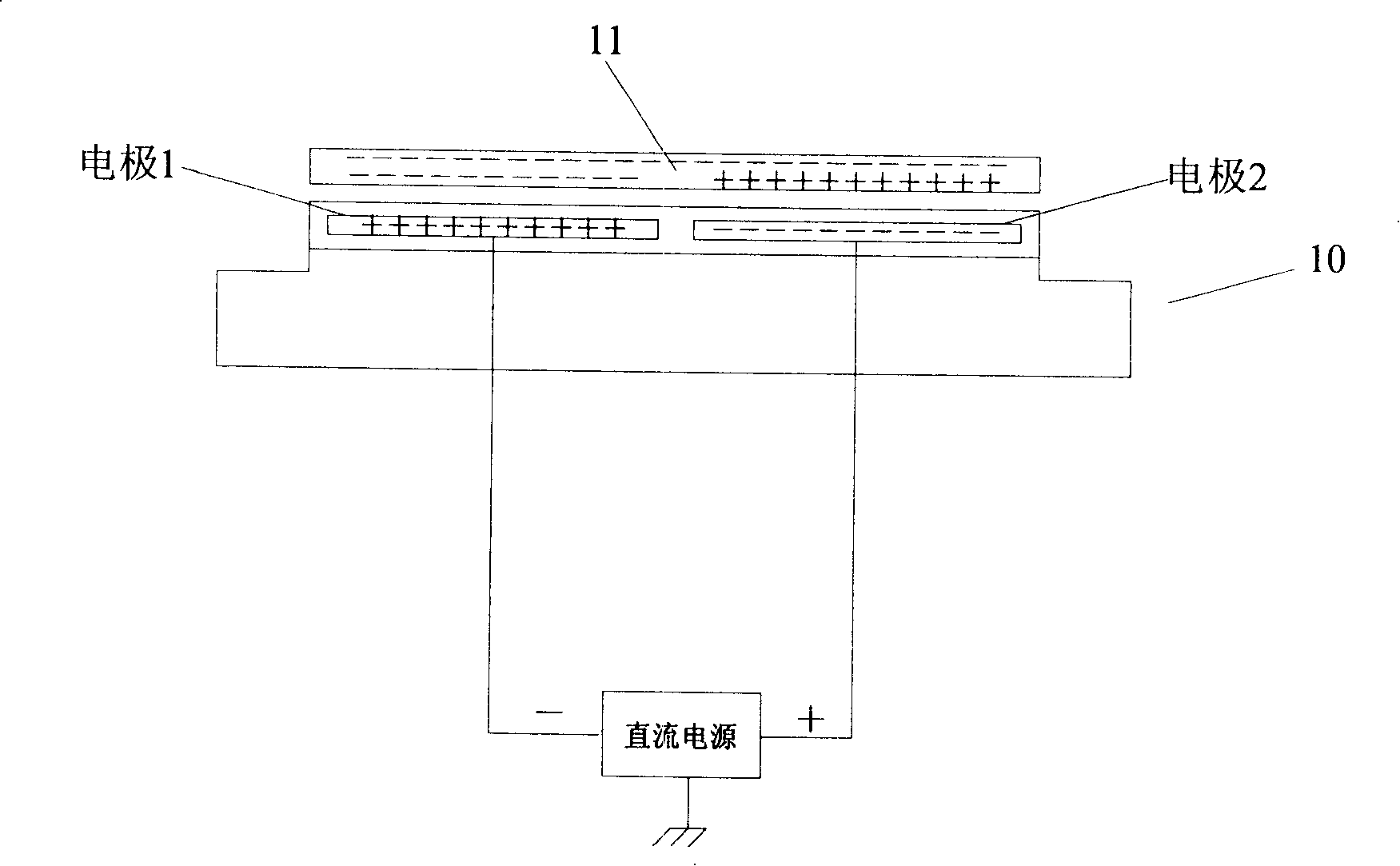

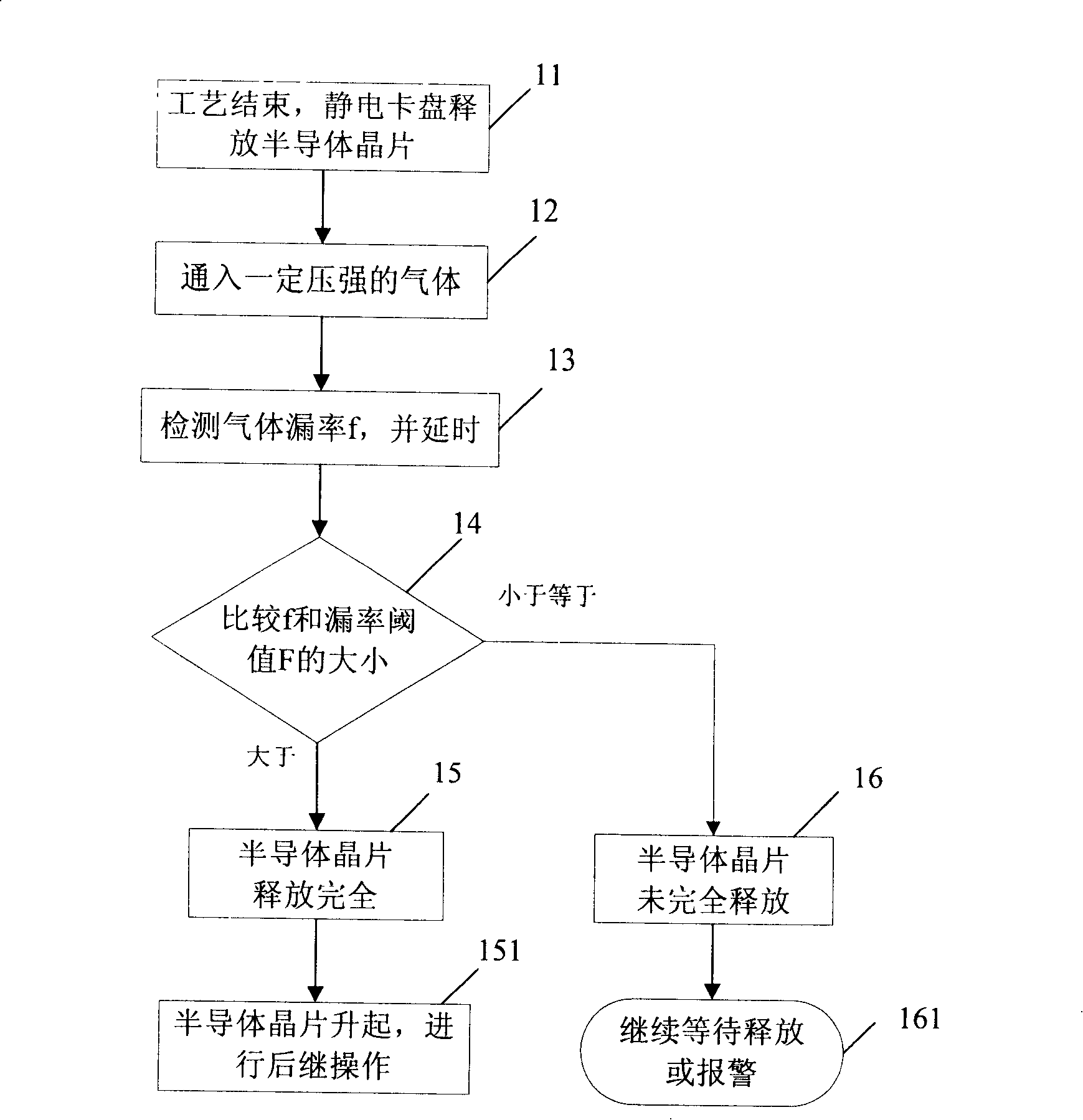

[0022] The invention provides a method for detecting the release degree of a semiconductor wafer from an electrostatic chuck. The core of the invention is: inject gas between the contact surface of the semiconductor wafer and the electrostatic chuck, and compare the detected gas leakage rate with the set The leakage rate threshold value is compared with the predetermined leakage rate, so as to judge the release degree of the semiconductor wafer according to the comparison result.

[0023] For better describing the present invention, now in conjunction with accompanying drawing, the method of the present invention is further described:

[0024] The operating process of the method of the present invention is as follows figure 2 As shown, the specific steps are,

[0025] Step 11: the process operation on the semiconductor wafer ends, and the electrostatic chuck releases the semiconductor wafer.

[0026] Step 12: Pass a gas between the contact surface of the semiconductor wafer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com