Silicon slice edge exposure system and its light intensity control method

An edge exposure and light intensity control technology, applied in the field of ultraviolet light exposure systems, can solve the problem of difficulty in accurately measuring exposure light intensity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

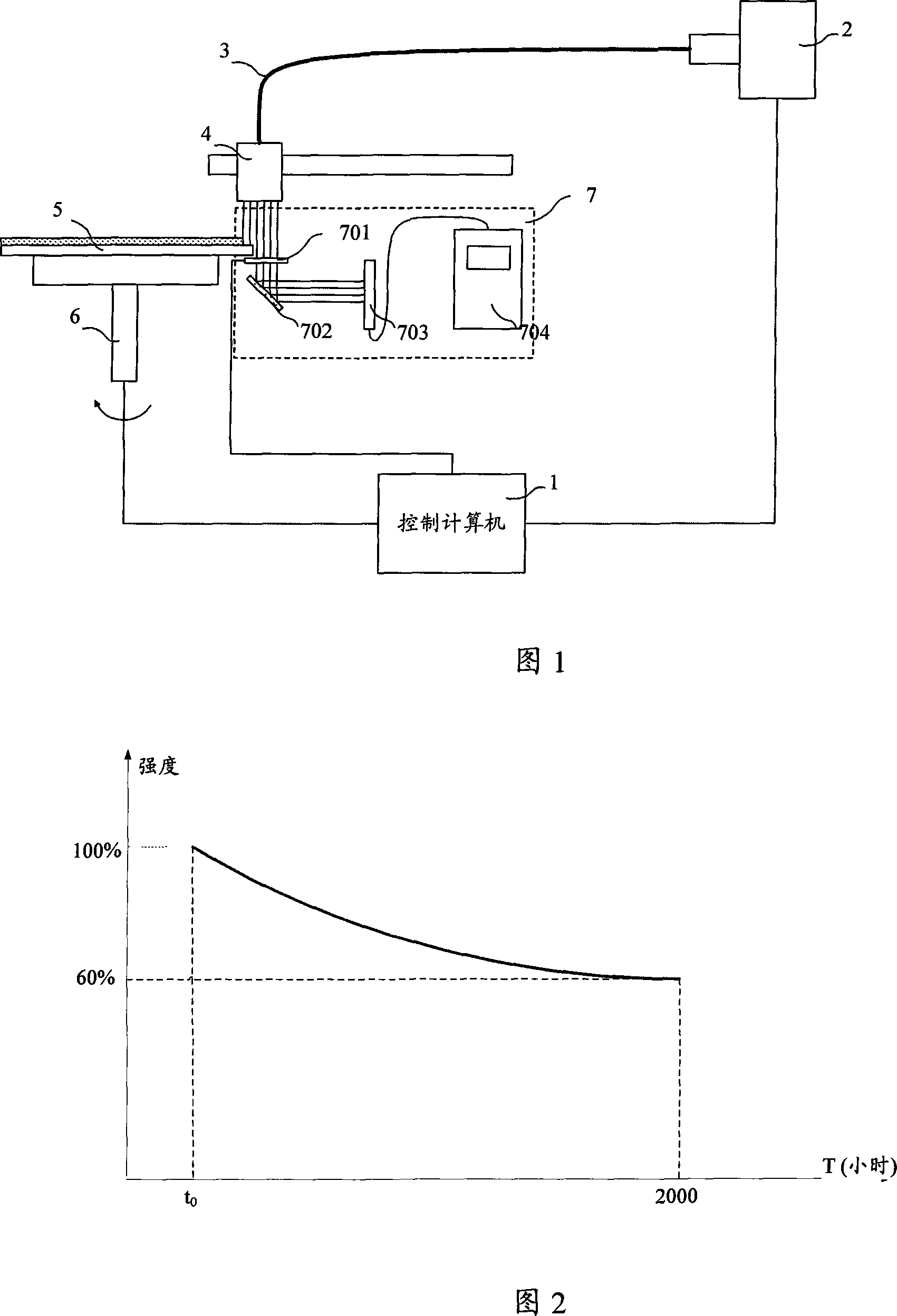

[0024] Figure 1 is a schematic diagram of the structure of the silicon wafer edge exposure system. The edge exposure system of the present invention is composed of a control computer 1 , a mercury lamp light source 2 , an optical fiber 3 , an imaging lens 4 , a silicon wafer carrier 6 and a light intensity control device 7 . The silicon wafer 5 coated with photoresist is placed on the silicon wafer carrying platform 6 . The light intensity control device 7 includes a measurement shutter 701 , a reflected light path 702 , a light intensity sensor 703 and a light meter 704 .

[0025] The control computer 1 controls the exposure light source 2 to switch on and off the light bulb, the shutter and set related parameters through the serial port. The exposure light source 2 can realize closed-loop feedback control based on its internal light inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com