High heat-resistance hollow out substrate working platform capable of multiple-surface depositing CVD diamond film

A diamond film, high thermal resistance technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of reduced bonding performance between coating and substrate, large performance impact, coating fragmentation, etc. Achieve the effect of increasing thickness uniformity, reducing residual stress and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings and embodiments.

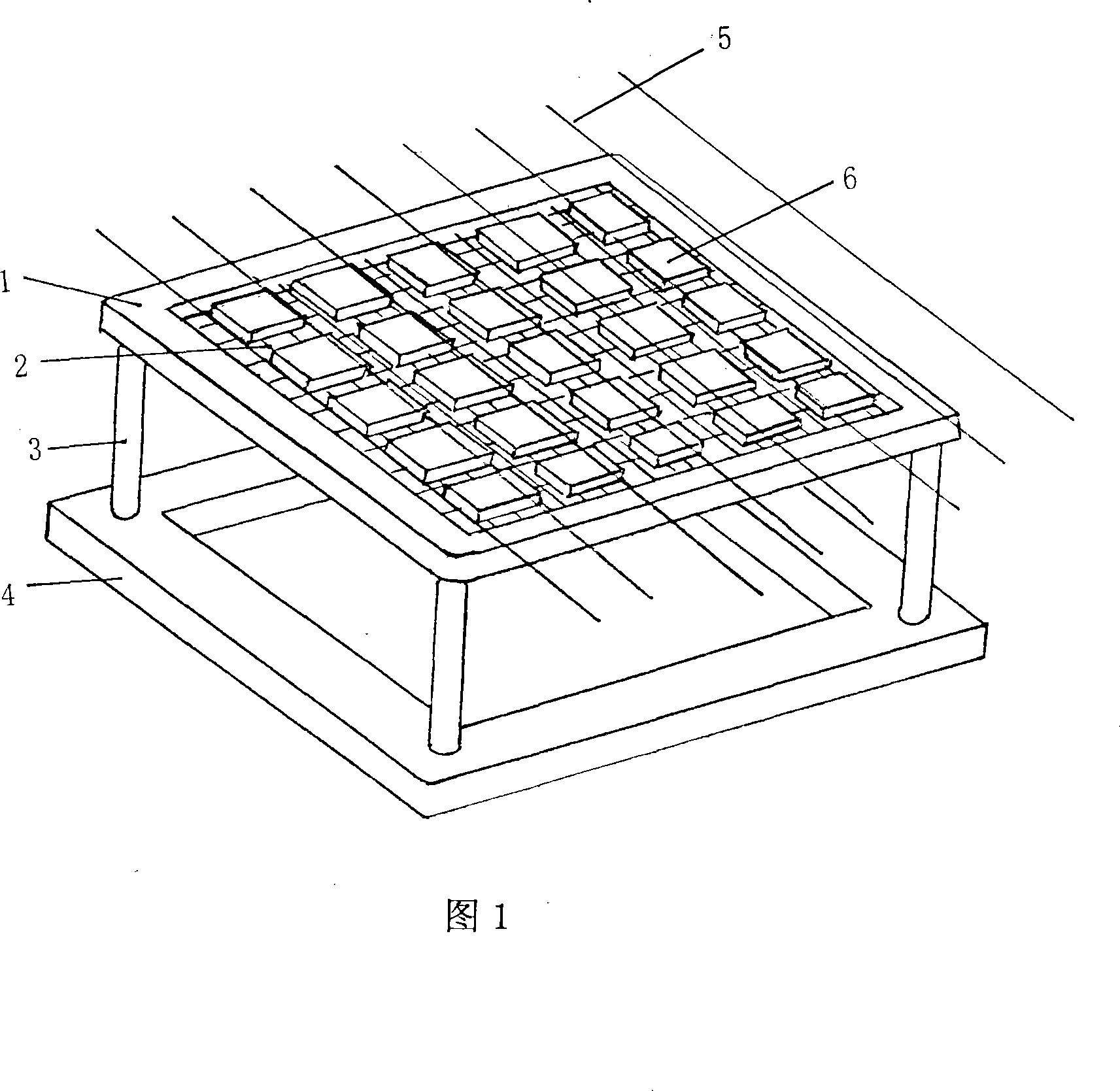

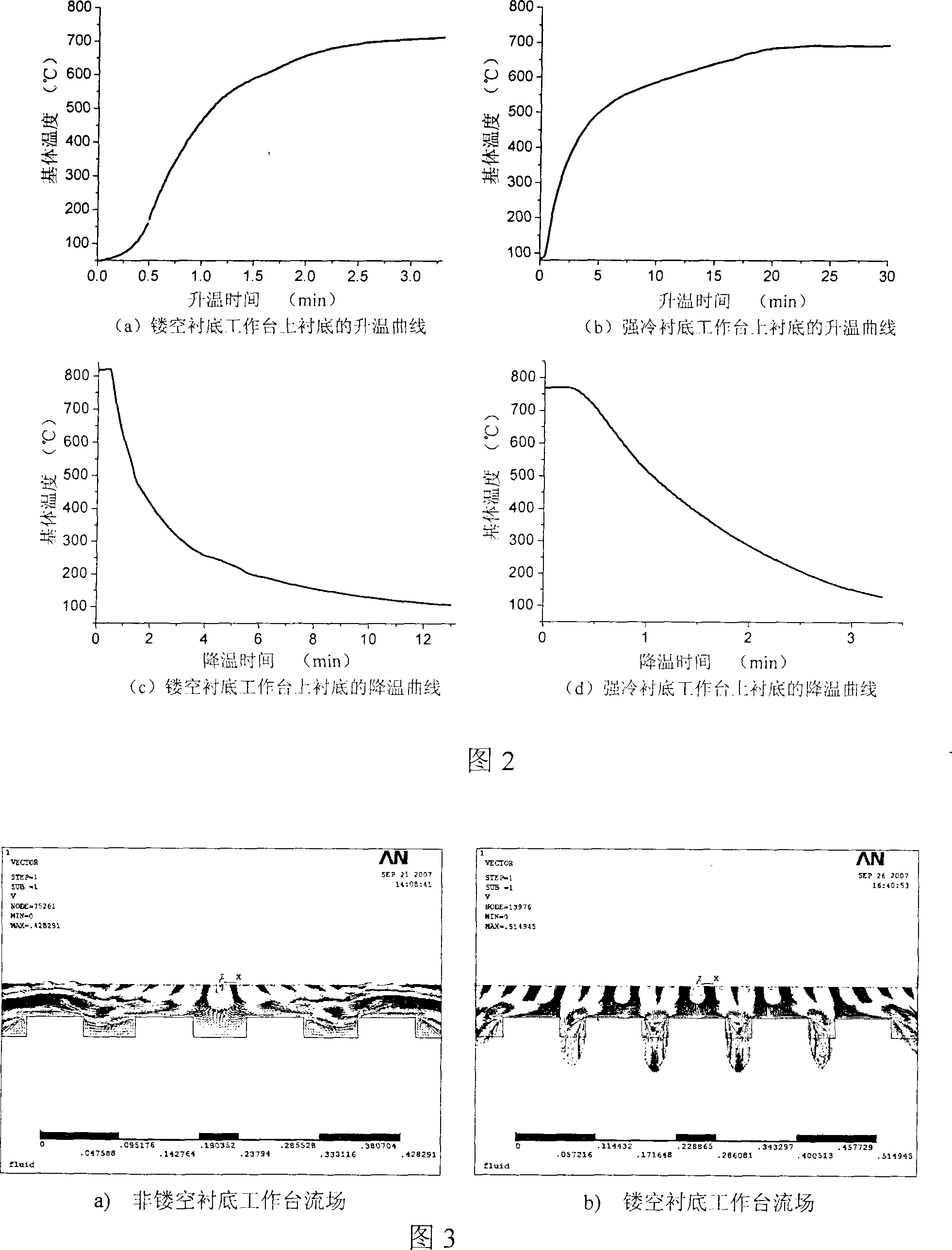

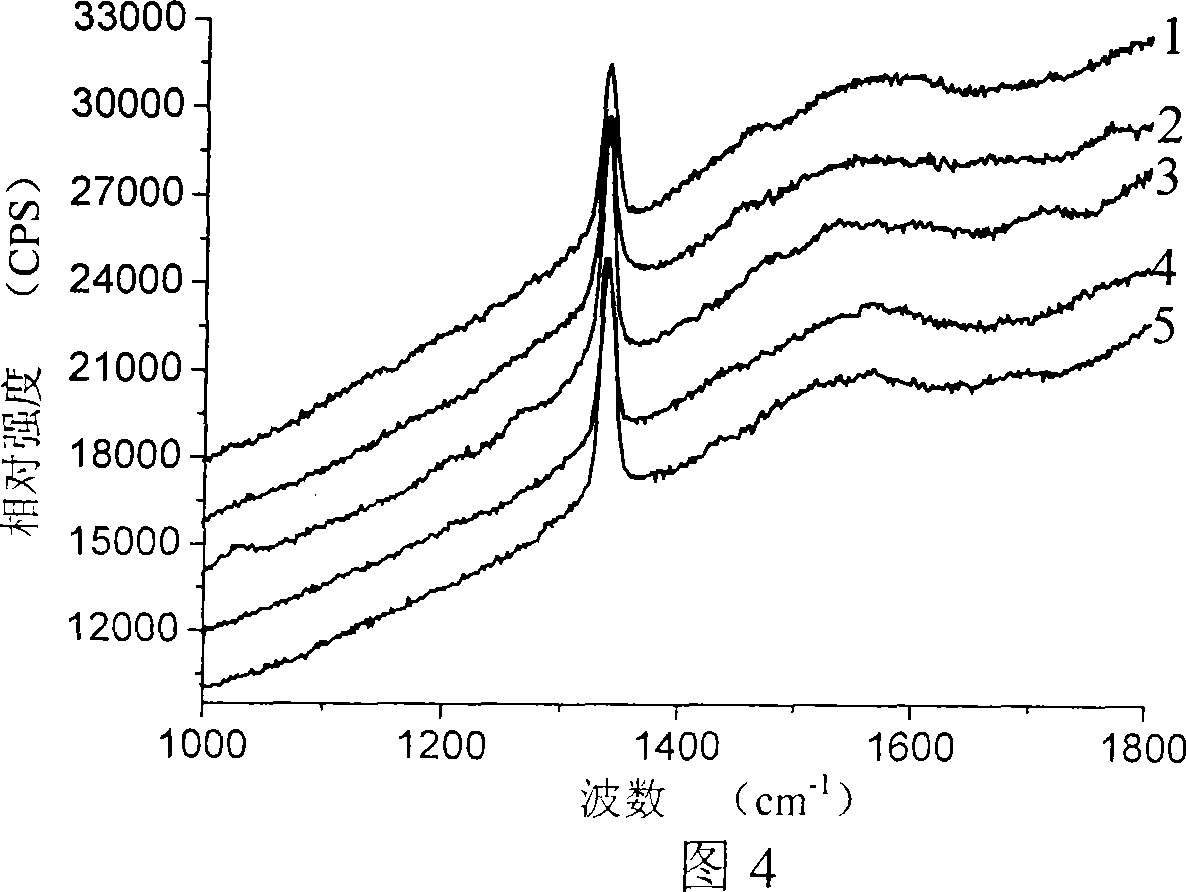

[0033] As shown in Figure 1, 2, 3, and 4.

[0034] A high thermal resistance hollow substrate workbench capable of depositing CVD diamond film on multiple sides. It is mainly composed of an upper frame 1, a screen 2, a support 3 and a support 4. The upper frame 1 is a graphite upper frame, and the screen 2 It is a braid of Mo, W, Ta or their alloy wires. The bracket 3 is a high-temperature resistant ceramic material with low thermal conductivity. The support 4 is a corrosion-resistant metal body (such as stainless steel), which is used to place a CVD diamond film that needs to be deposited on multiple sides. The screen 2 of the base 6 is installed in the upper frame 1. The upper frame 1 is connected by at least three supports 3 (four in Figure 1) supports 4, and the screen 2 is parallel to the bottom surface of the supports 4, as shown in Figure 1. Shown.

[0035]In spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com