Fumigation medicament vaporization administration device

A technology of medicament and temperature control device, which is applied to fumigators, devices for catching or killing insects, applications, etc., can solve problems such as poor temperature controllability, poor fumigation effect, and low vaporization efficiency, and achieve strong temperature controllability , good use effect, good vaporization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

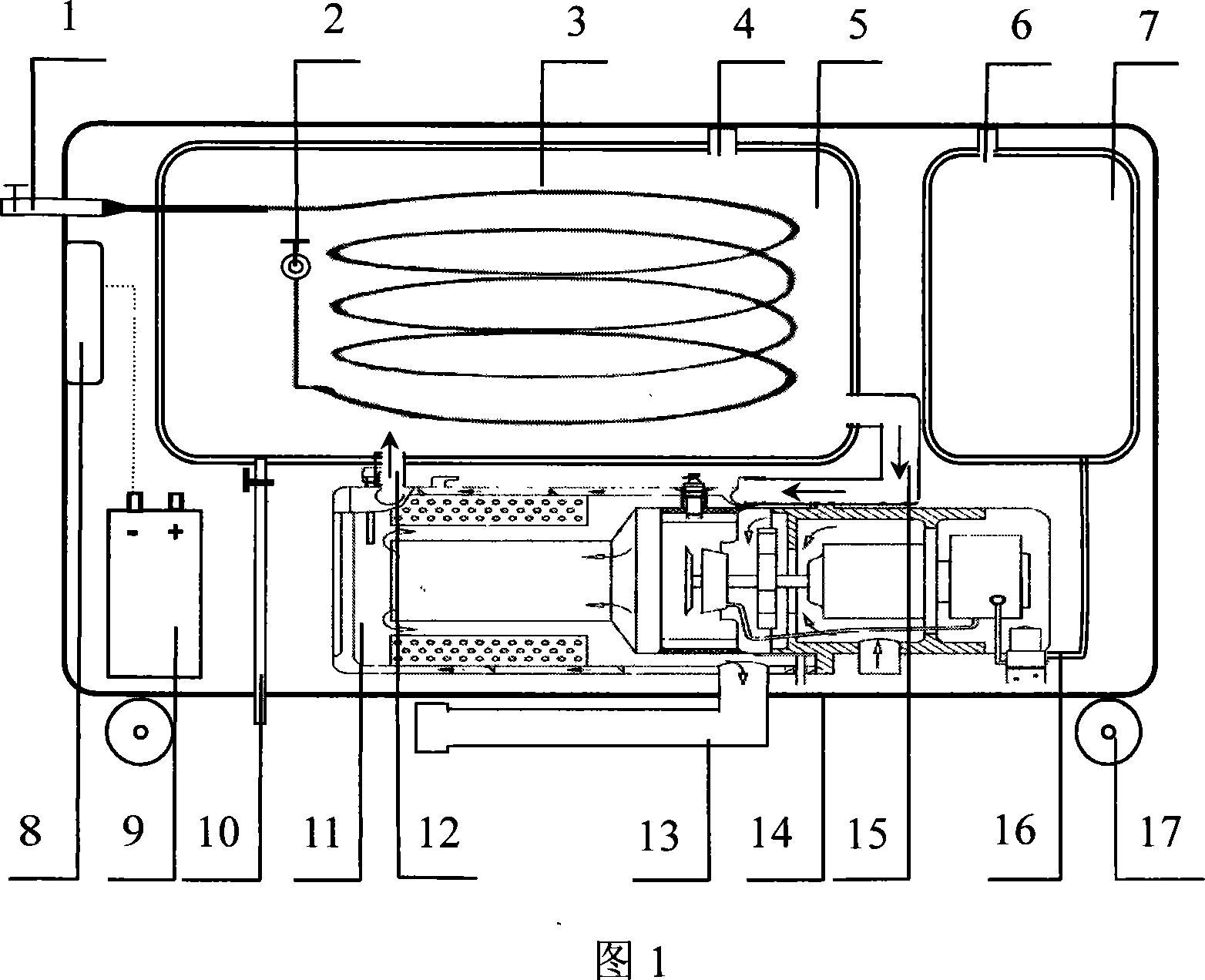

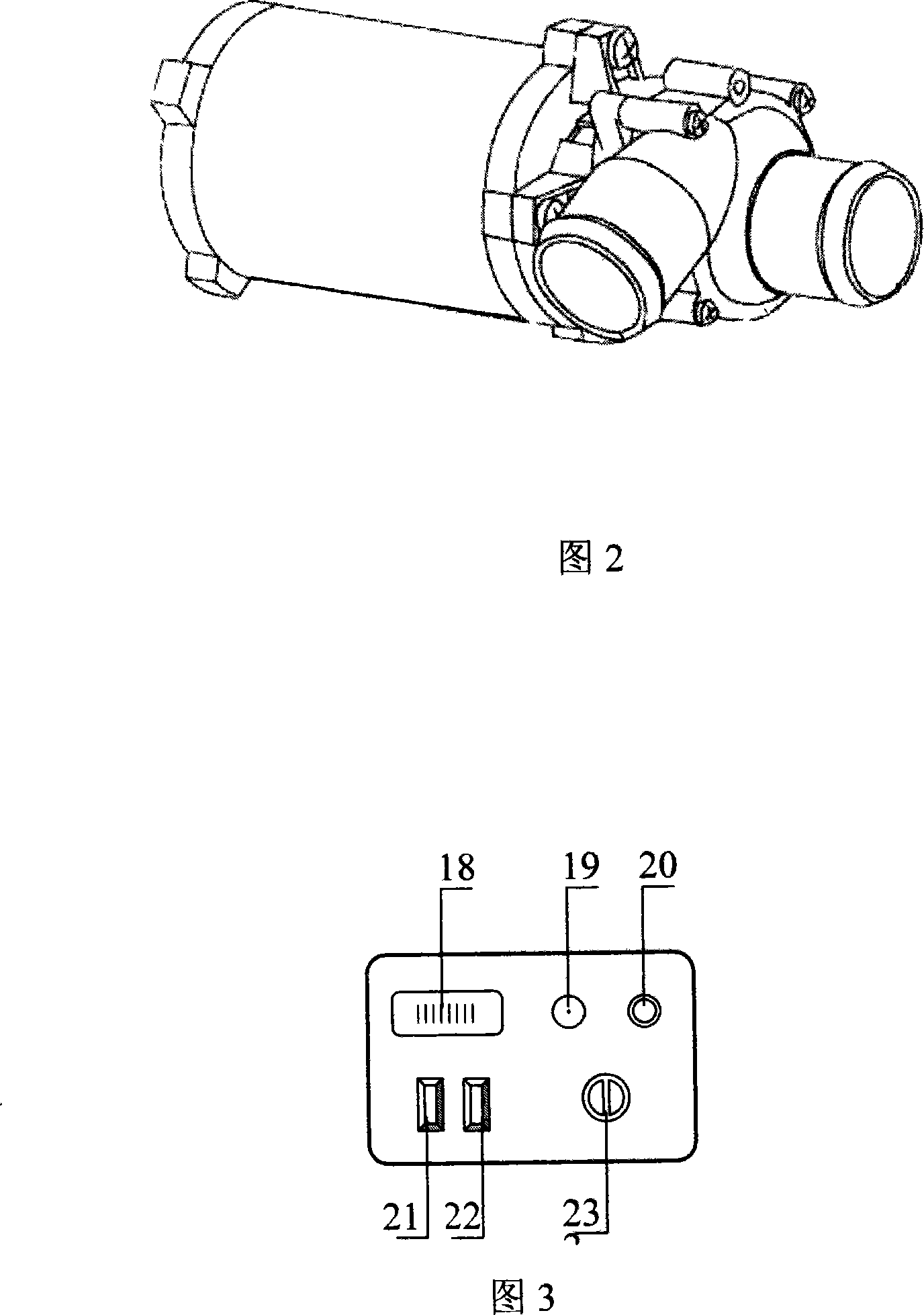

[0014] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings. As shown in Figures 1 and 2, this fumigation agent vaporization dosing device is provided with a box body 14 with a bottom wheel 17, and a fuel oil heater 11 is installed inside the box body 14, and its model is YJ-Q16.3 / A (H), produced by Hebei Hongye Machinery Co., Ltd. Heater 11 is provided with temperature control device, can automatically control heating process, will stop heating when water temperature reaches 78 ℃, starts heating when water temperature drops to 65 ℃. The power supply of the temperature control device is a 12V battery. When the battery is fully charged, it can continuously supply power to the device for more than 6 hours. The fuel oil heater 11 is fueled by the fuel tank 7, and the fuel tank 7 provides diesel fuel for the heater 11 to work. The exhaust system of fuel oil type heater 11 is the exhaust pipe 13 that is connected on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com