Method for preparation of organic/inorganic composite proton exchanging membrane used for fuel cell

A technology of proton exchange membrane and inorganic compounding, which is applied to fuel cell parts, fuel cells, solid electrolyte fuel cells, etc., can solve the problems of low proton conductivity, achieve high strength, excellent proton conductivity, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

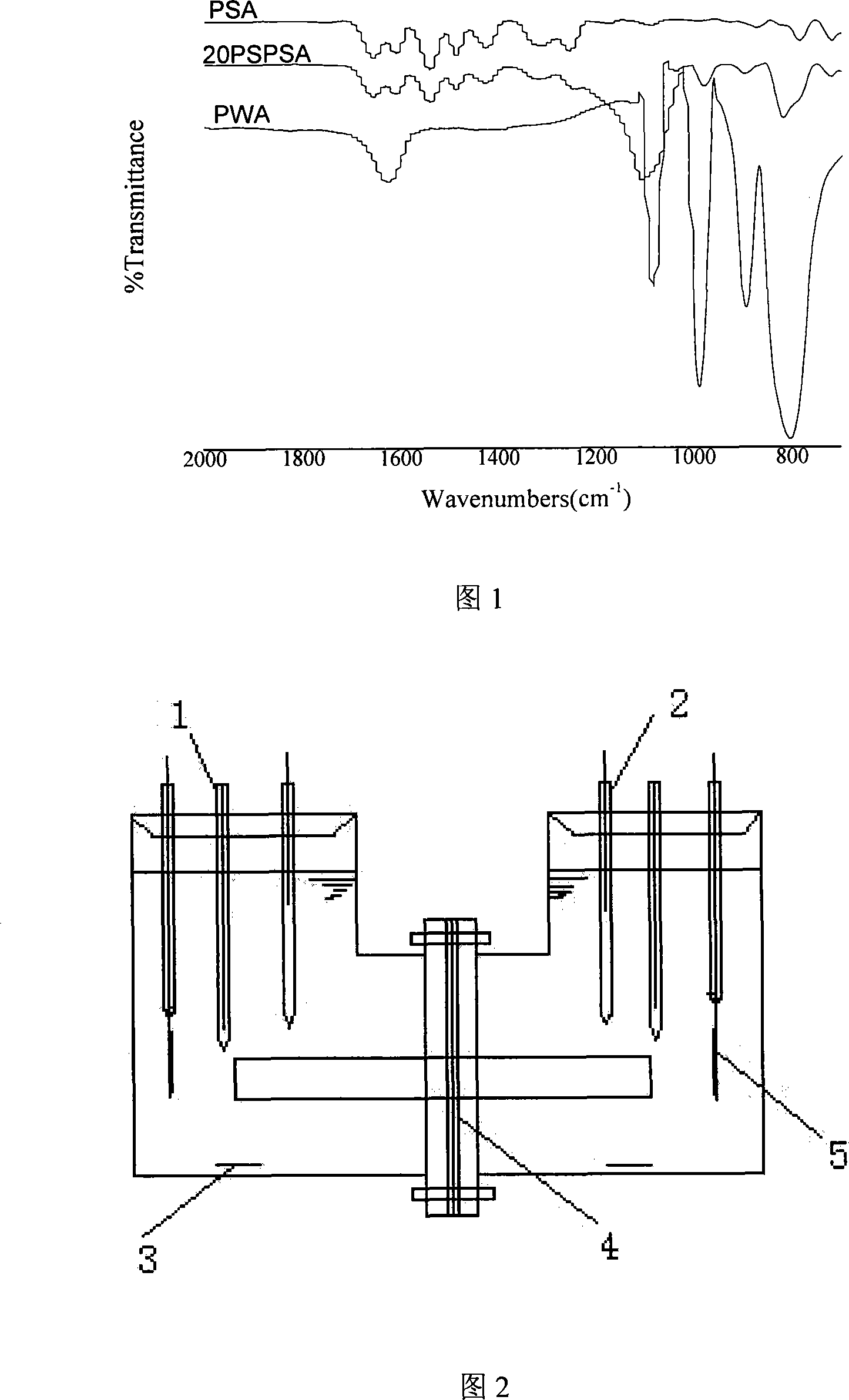

Method used

Image

Examples

Embodiment 1

[0022] Weigh 1g of polysulfone amide, wash and dry, add DMAC, heat and dissolve to form a DMAc solution with a concentration of 15% PSA, add 0.1g of phosphotungstic acid powder while stirring, stir well, drop by drop while stirring Add 0.15g nano-SiO 2 Silica sol (phosphotungstic acid and SiO 2 The weight ratio of the total amount to polysulfone amide is 20:80, that is, phosphotungstic acid and SiO 2 20% of the total weight. Among them, phosphotungstic acid accounts for 8% of the total weight, SiO 2 was 12%), and evenly vibrated with ultrasonic waves. Adjust the first homogenizing speed of the KW-4A desktop homogenizer to 600 rpm and the second homogenizing speed to 1800 rpm, and place the special thin 3cm×3cm square glass piece on the suction cup of the homogenizer , Align the center of the suction cup and the glass sheet, turn on the glue homogenizer and drop the mixed solution onto the glass sheet at the same time, after coating evenly, put the glass sheet with the mixe...

Embodiment 2

[0025] According to the method described in Example 1, 30% phosphotungstic acid and SiO are mixed in the DMAc solution of 10% PSA 2 , of which phosphotungstic acid accounts for 13.5% of the total weight, SiO 2 It accounts for 16.5%, and the film is prepared according to the method of Example 1 after shaking evenly. The measured proton conductivity of the membrane at 90°C is 2.01×10 -2 S / cm, the water content of the film is 34.21%, the swelling degree is 3.6%, the tensile breaking strength is 34.2Mpa, the breaking elongation is 20.6%, and the thermal decomposition temperature is about 420°C.

Embodiment 3

[0027] According to the method described in Example 1, in the DMAc solution of 20% PSA, mix 40% phosphotungstic acid and SiO 2 , where phosphotungstic acid accounts for 16% of the total weight, SiO 2 Accounting for 24%, the film was prepared according to the method of Example 1 after shaking evenly. The measured proton conductivity of the membrane at 90°C is 2.43×10 -2 S / cm, the water content of the film is 39.01%, the swelling degree is 3.6%, the tensile breaking strength is 29.9Mpa, the breaking elongation is 17.1%, and the thermal decomposition temperature is about 420°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com