Compatibilizer used for ABS composition and ABS composition having the same

A technology of compatibilizer and composition, applied in the field of ABS composition, which can solve the problems of poor balance between impact resistance and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

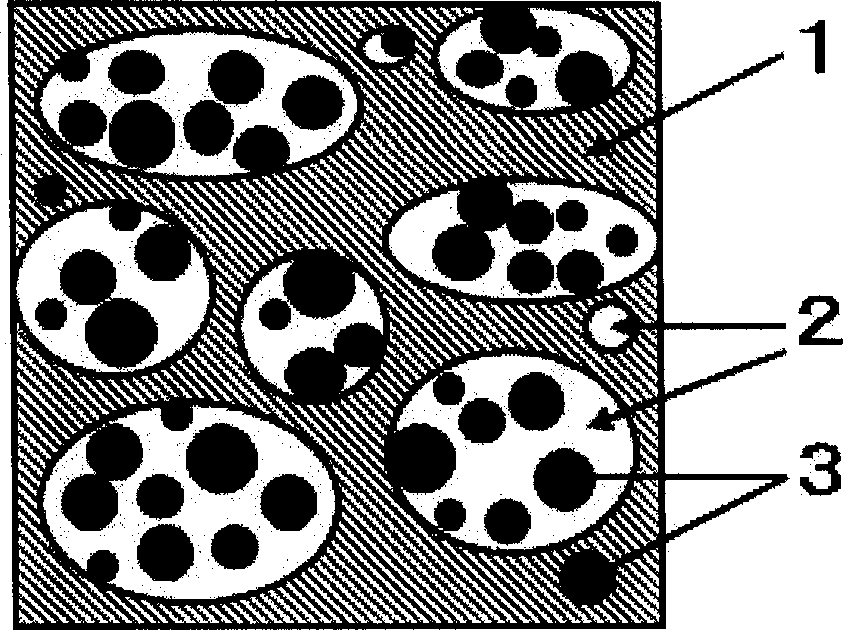

Method used

Image

Examples

Embodiment 1

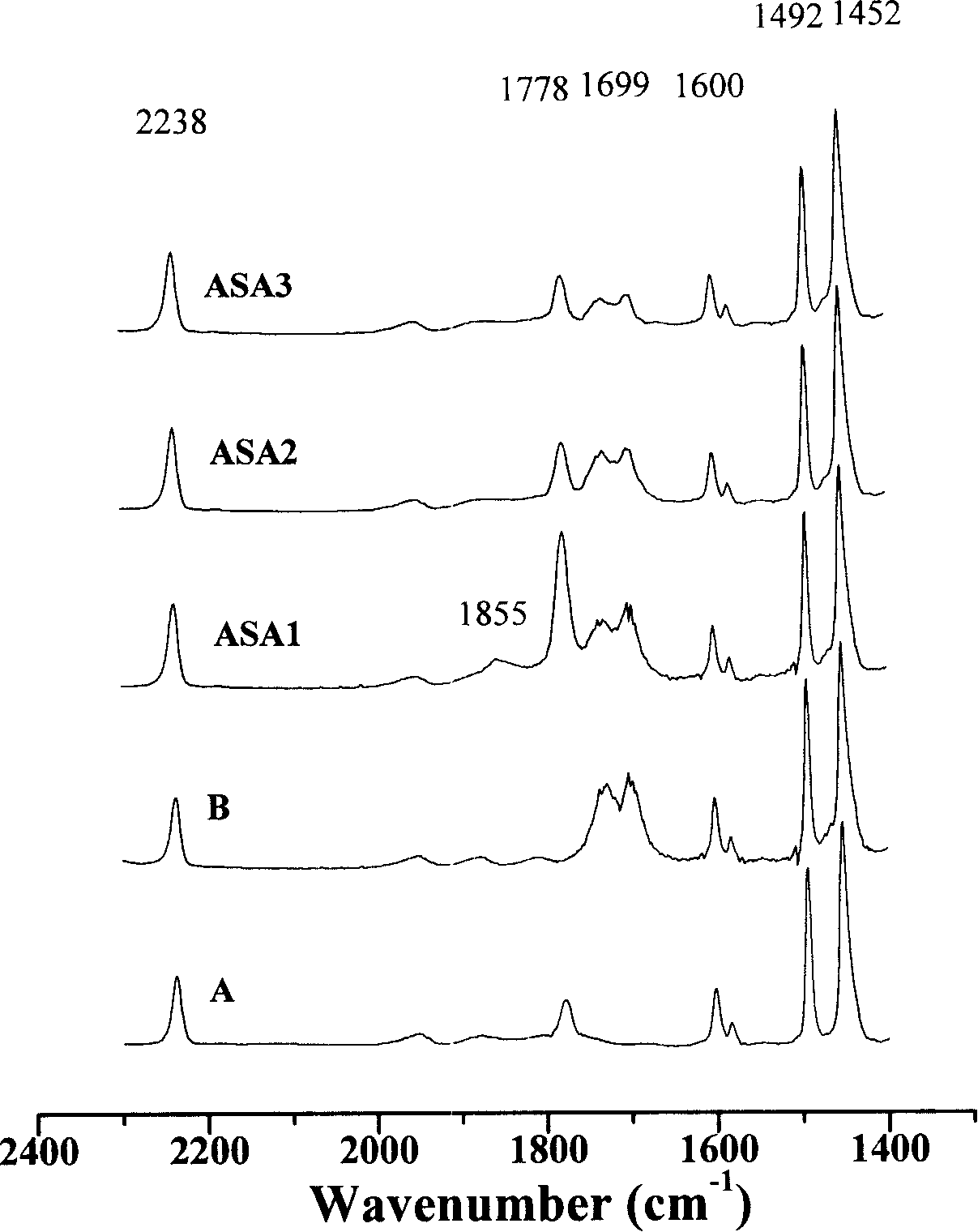

[0063] Styrene, acrylonitrile and methacrylic acid are firstly refined by vacuum distillation, and maleic anhydride and benzoyl peroxide are refined by recrystallization.

[0064] In a 4-necked glass bottle with a volume of 1 liter, add 225 grams of butanone and 125 grams of toluene, then add 70 grams of refined styrene, 25 grams of acrylonitrile and 10 grams of methacrylic acid in sequence, and finally add 0.3 grams of refined The obtained benzoyl peroxide was completely dissolved and mixed uniformly to obtain solution B. The glass bottle was heated in an oil bath at 120° C. and the mixture in the glass bottle was stirred with a stirrer at a stirring rate of 120 rpm.

[0065] Then the A solution made of 33 grams of styrene obtained after the refining treatment, 65 grams of acrylonitrile, 4 grams of maleic anhydride and 0.3 grams of benzoyl peroxide was slowly added dropwise to the glass bottle, and the time of dropping was 6 hours. During the dropwise addition process, the gl...

Embodiment 2

[0067] The preparation method is the same as in Example 1, wherein 6 grams of methacrylic acid, 0.6 grams of benzoyl peroxide, and 2 grams of maleic anhydride are added, and the addition amounts of the remaining components are the same as in Example 1, and the final product is identified as ASA2.

Embodiment 3

[0069] The preparation method is the same as in Example 1, wherein 2 grams of methacrylic acid, 0.8 grams of benzoyl peroxide, and 1.5 grams of maleic anhydride are added, and the addition amounts of the remaining components are the same as in Example 1, and the final product is marked as ASA3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com