Discarded high foaming plastics regeneration pelleting process

A high-foaming, plastic technology, applied in the field of polymer recycling technology, can solve the problems of difficult to form a recycling market, high labor intensity, low handling efficiency, etc., to achieve large market potential and practicability, production environment improvement, and protection. health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

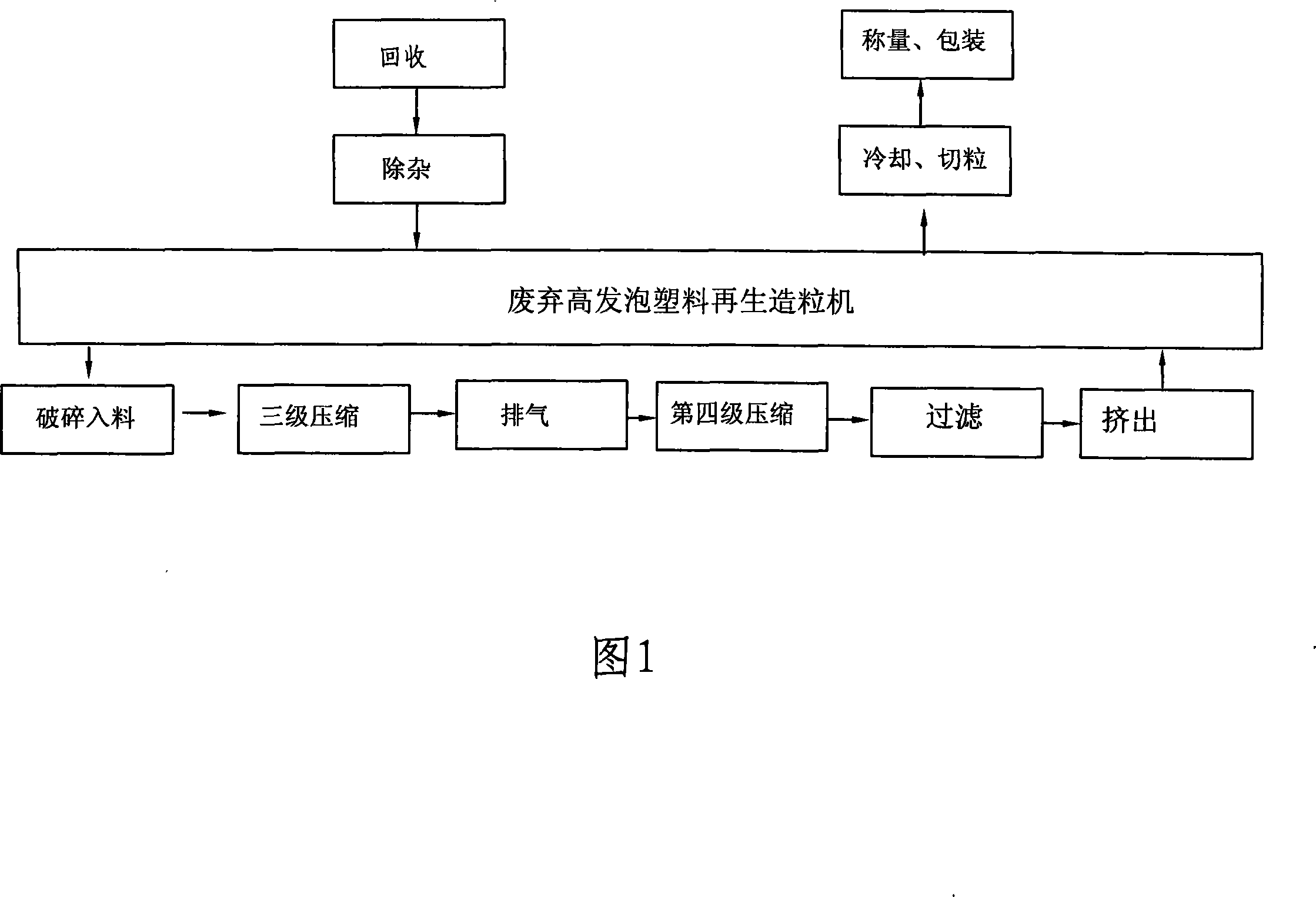

[0049] Below in conjunction with accompanying drawing, the present invention is further described, see shown in accompanying drawing 1, waste foamed plastic regeneration granulation process, comprises the following steps:

[0050] (1) Discarded EEP high foaming plastics;

[0051](2) Impurity removal, removing other impurities from the recycled waste EPE high foaming plastic;

[0052] (3) The waste high foaming plastic recycling granulator completes the following functions:

[0053] (A) Crushing and feeding, transfer the waste EPE foamed plastics through step (2) into the hopper of the waste high foaming plastic regeneration granulator, and use the crushing device in the waste high foaming plastic regeneration granulator hopper to crush the waste EPE The high-foaming plastic is crushed into blocks. The crushing device is a combination of a square shear knife and a square static knife. The thickness of the square shear knife is 20mm. The waste foamed plastic polyethylene is br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com