Multiphase catalytic oxidation cyclohexane catalyst for cyclohexanone and cyclohexanol and preparation method thereof

A heterogeneous catalyst and catalytic oxidation technology are applied in the preparation of oxidation reaction, chemical instruments and methods, preparation of organic compounds, etc., which can solve the problems of high price, clogging of the reactor, and high price, and achieve high conversion rate of cyclohexane, Mild reaction conditions and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

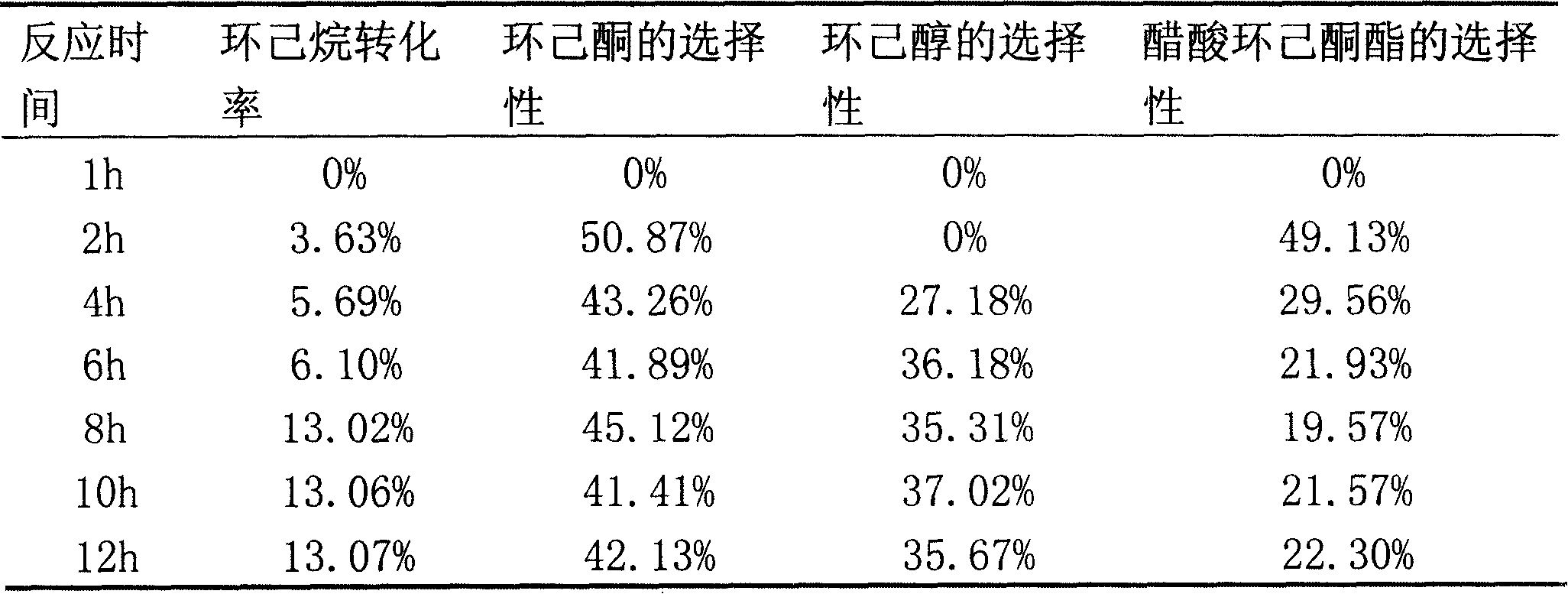

Examples

Embodiment 1

[0024] Embodiment 1: The ZSM-5 (silicon-aluminum ratio is 50) powder that takes 2g joins in the copper nitrate solution that 40ml concentration is 0.1mol / L, stirs at room temperature for 3 hours, then leaves standstill for 5 hours, centrifuges After separation, the solid sample was dried at 90°C, and then baked in a high-temperature furnace at 400°C for 2.5 hours. Cu-ZSM-5 with a Cu content of 2.1% was prepared.

[0025] 10 ml of cyclohexane, 10 ml of acetic acid, 1 ml of butanone, and 0.02 g of the Cu-ZSM-5 catalyst prepared above were added to a 50 ml tank reactor. Molecular oxygen was introduced to keep the pressure at 0.85 MPa, the reaction temperature was 130° C., and the reaction time was 5 hours. Reaction result: the conversion rate of cyclohexane is 4.88%, the selectivity of cyclohexanone is 56.10%, the selectivity of cyclohexanol is 9.60%, the rest is cyclohexanol acetate, and no carbon dioxide and black oil are produced.

Embodiment 2

[0026] Embodiment 2: The ZSM-5 (silicon-aluminum ratio is 50) powder that takes 2g joins in the cobalt nitrate solution that 40ml concentration is 0.05mol / L, stirs at room temperature for 3 hours, then leaves standstill for 5 hours, centrifuges After separation, the solid sample was dried at 90°C, and then baked in a high-temperature furnace at 400°C for 2.5 hours. Co-ZSM-5 with a Co content of 1.8% was prepared.

[0027] 10 ml of cyclohexane, 10 ml of acetic acid, 1 ml of butanone, and 0.02 g of the Co-ZSM-5 catalyst prepared above were added into a 50 ml tank reactor. Molecular oxygen was introduced to keep the pressure at 1.2 MPa, the reaction temperature was 110° C., and the reaction time was 10 hours. Reaction results: the conversion rate of cyclohexane is 4.23%, the selectivity of cyclohexanone is 59.40%, the selectivity of cyclohexanol is 9.42%, the rest is cyclohexanol acetate, and no carbon dioxide and black oil are produced.

Embodiment 3

[0028] Embodiment 3: the ZSM-5 (silicon-aluminum ratio is 50) powder that takes 2g joins in the ferric nitrate solution that 40ml concentration is 0.1mol / L, is placed on stirring at room temperature 3 hours, then leaves standstill 5 hours, After centrifugal separation, the solid sample was dried at 90°C, and then baked in a high-temperature furnace at 400°C for 2.5 hours. Using the obtained Fe-ZSM-5 as a starting material, add ferric nitrate solution, repeat the preparation procedure once according to the aforementioned conditions and steps, and obtain Fe-ZSM-5 with an Fe content of 1.9%.

[0029] 10 ml of cyclohexane, 10 ml of acetic acid, 1 ml of butanone, and 0.02 g of the Fe-ZSM-5 catalyst prepared above were added to a 50 ml tank reactor. Molecular oxygen was introduced to keep the pressure at 0.5 MPa, the reaction temperature was 150° C., and the reaction time was 5 hours. . The reaction results are as follows: the conversion rate of cyclohexane is 2.55%, the selectivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com