Method of making ZnO ultraviolet photoconductive detector with vertical structure

A vertical structure, ultraviolet light technology, applied in the field of photoelectric detection, can solve the problems of difficult preparation, poor reliability and repeatability, and achieve the effect of simple preparation process, easy control, and beneficial to photoelectric integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

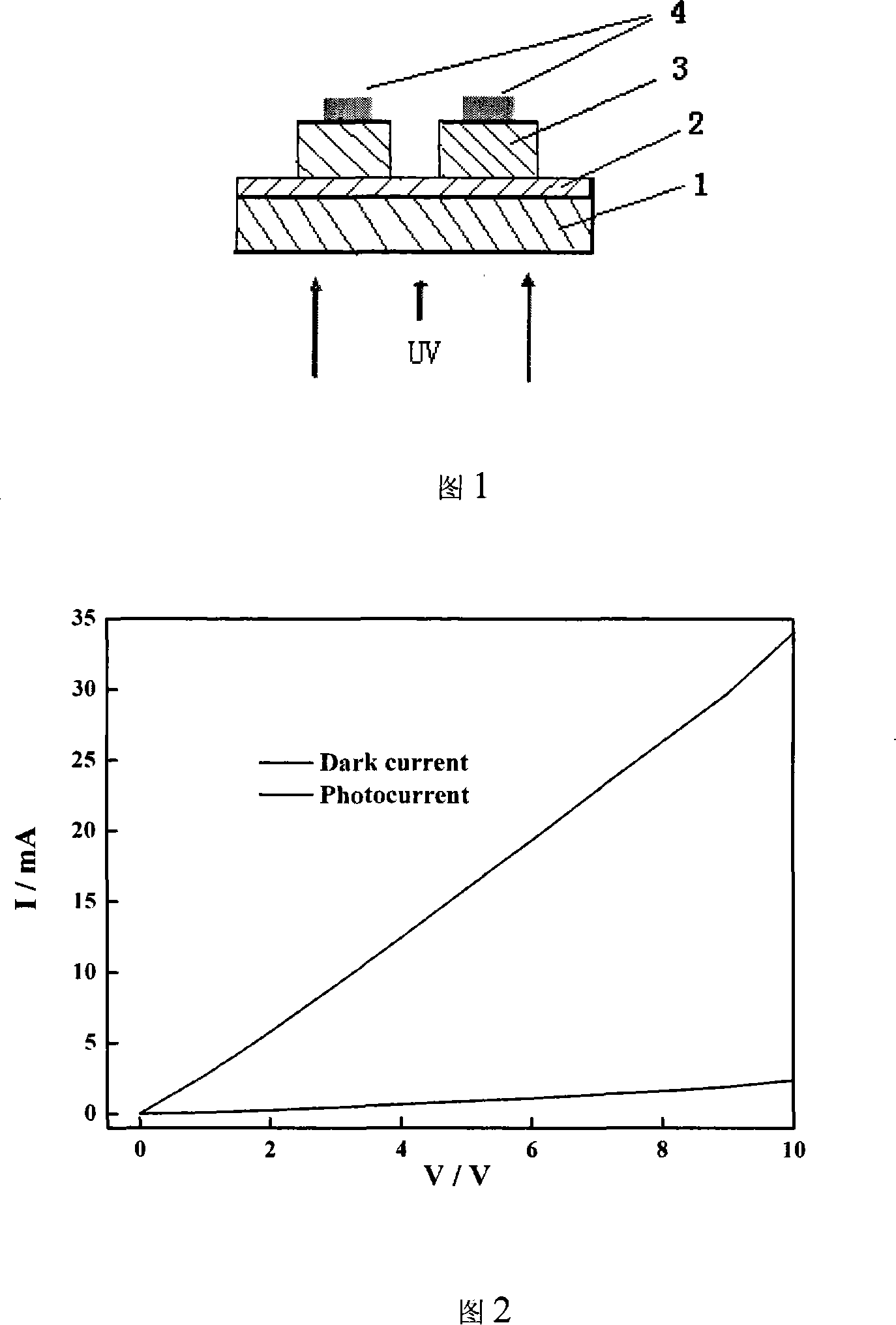

[0017] The present invention deposits transparent and conductive ITO thin film 2 and ZnO thin film 3 successively on quartz glass or sapphire substrate 1, and heat treatment at 400 ℃ in oxygen for one hour, then use concentration of about 20% NH 4 The sample is corroded by the Cl solution to expose the ITO film 2 to form a ZnO mesa, and finally a metal Al electrode 4 is deposited on the surface of the ZnO mesa to obtain a ZnO ultraviolet photoconductive detector with a vertical structure. In the present invention, the thicknesses of the ITO film and the ZnO film deposited on the substrate by radio frequency reactive sputtering (RF Sputtering) are about 150 nm and 600 nm, respectively. During the deposition, an appropriate amount of oxygen is introduced into the vacuum chamber, and the introduction of oxygen can reduce the O vacancies generated during the growth process, making the ZnO film closer to the complete stoichiometric ratio; then, place the ZnO film horizontally in a q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com