Surface decoration and process for making the same

A surface decoration and manufacturing technology, applied in decorative arts, special decorative structures, printing devices, etc., can solve problems such as grinding or scratching, high mold processing costs, increased cost and pollution, etc. The effect of reducing expenses and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

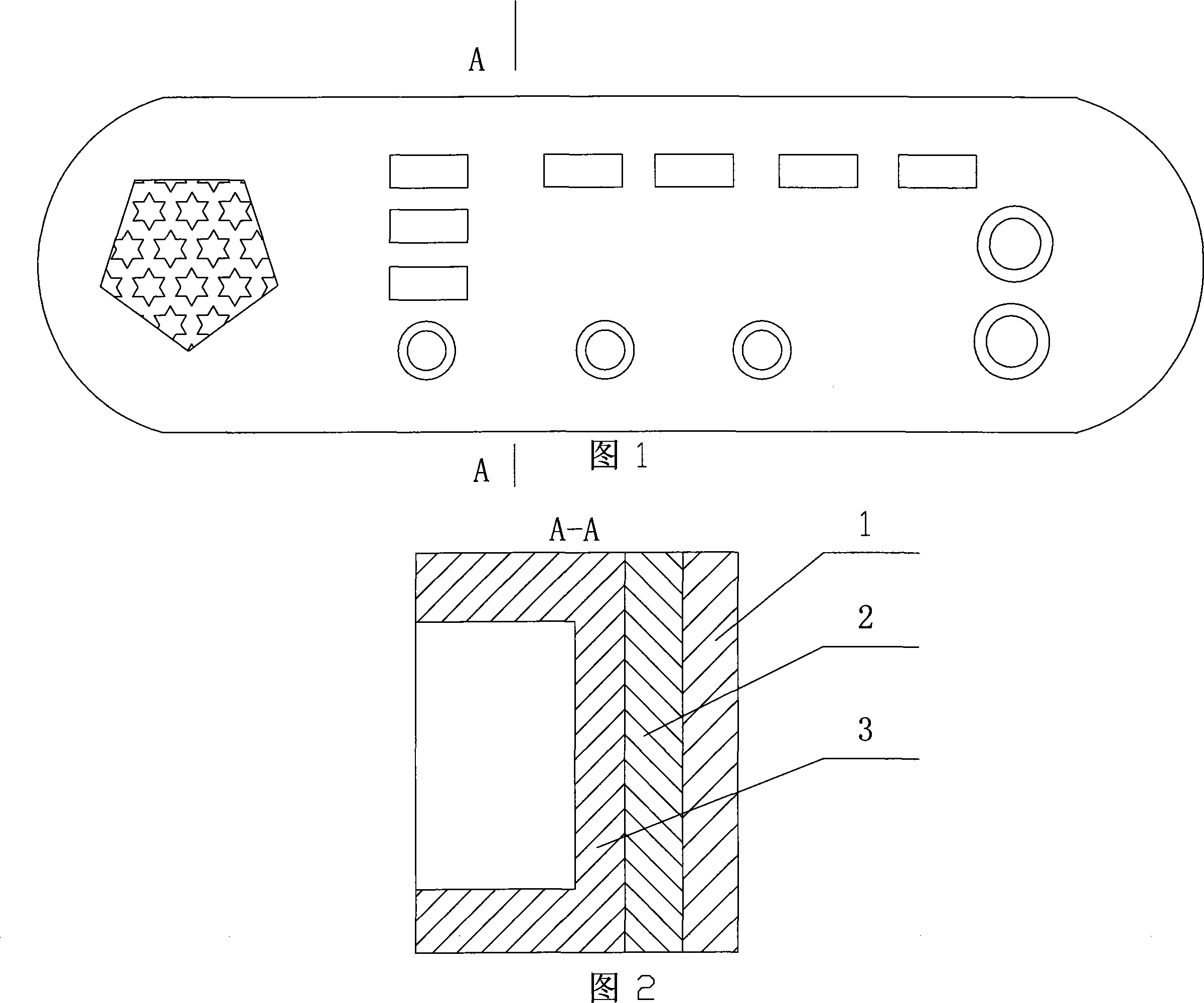

[0031] Example 1: Front control of Little Swan washing machine 3608

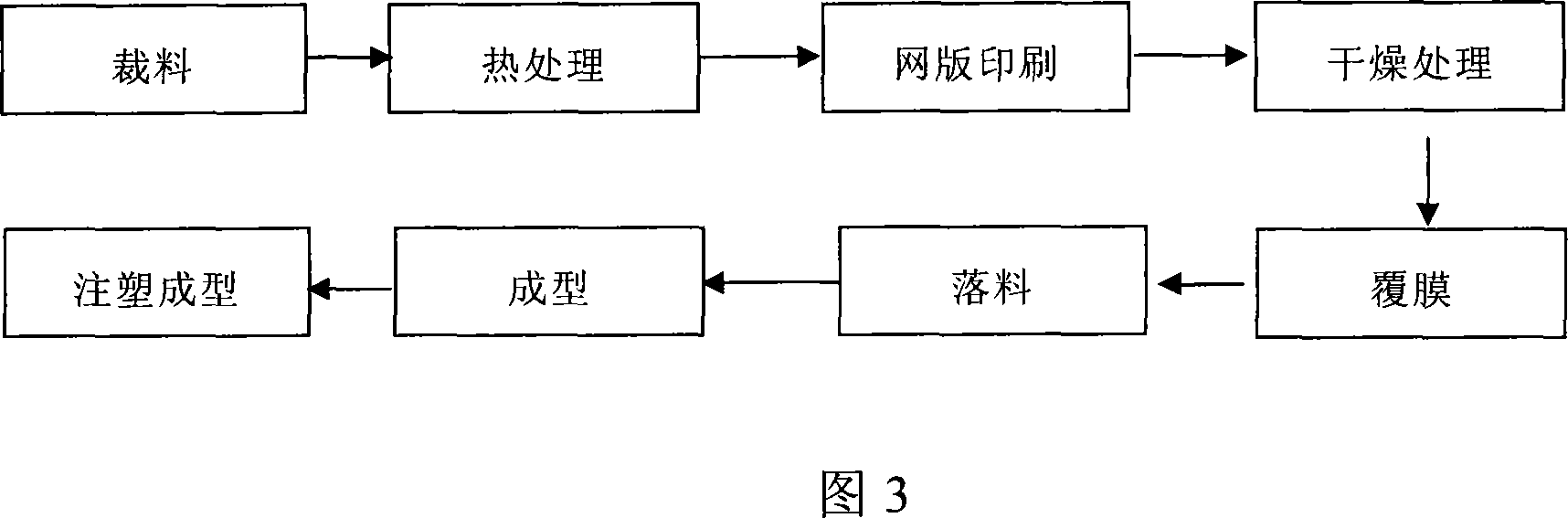

[0032] 1. Cutting (the whole roll of PET film material): fix the whole roll of film on the cutting machine and cut out the transparent sheet of the required size 1.

[0033] 2. Heat treatment: Put the transparent sheet 1 into a constant temperature oven for heat treatment. The heat treatment temperature is 70°C, and the heat treatment time is 30 minutes;

[0034] 3. Screen printing:

[0035] (1) According to the drawing, the computer makes the film of the required size. The position of the punching hole in the next process is printed on the film, and then the screen is made according to the size of the film.

[0036] (2), print the sample ink pattern 2 on the screen printing machine on the back of the transparent sheet 1, and its thickness is: 0.03mm; the screen plate is selected from 80 to 400 mesh, PET Y mesh, 20N / cm tension, squeegee 75°. Ink: Solvent-based ink is selected from Jujo Japan and Baolong HT...

Embodiment 2

[0047] Example 2: Front cavity of 868G washing machine in China and Japan

[0048]1. Cutting material: choose the whole roll of PC film material: cut out the transparent sheet of the required size 1.

[0049] 2. Heat treatment: Put the transparent sheet 1 into a constant temperature oven for heat treatment. The heat treatment temperature is 70°C, and the heat treatment time is 40 minutes;

[0050] 3. Screen printing:

[0051] (1) Make the screen version according to the requirements of the drawings.

[0052] (2), print the sample ink pattern 2 on the screen printing machine on the back of the transparent sheet 1, and its thickness is: 0.04mm; the screen plate is selected from 80 to 400 mesh, PET Y mesh, 20N / cm tension, squeegee 78 °. Ink: select the same ink as embodiment one.

[0053] (3) Apply ink full-screen adhesive or water-based protective film on the transparent sheet printed with pattern ink pattern 2 to increase the bonding force with the injection molding material...

Embodiment 3

[0062] Embodiment 3: Little Swan washing machine 506 handle

[0063] 1. Cutting material: choose the whole roll of PC film material or PET film material): cut out the transparent sheet of the required size 1.

[0064] 2. Heat treatment: Heat the transparent sheet 1, the heat treatment temperature is 70°C, and the heat treatment time is 30 minutes;

[0065] 3. Screen printing:

[0066] (1) According to the drawing, the computer makes the film of the required size. The position of the punching hole in the next process is printed on the film, and then the screen is made according to the size of the film.

[0067] (2), print the sample ink pattern 2 on the screen printing machine on the back of the transparent sheet 1, and its thickness is: 0.06mm; the screen plate is selected from 80 to 400 mesh, PET Y mesh, 20N / cm tension, and a squeegee at 80°. Ink: Use solvent-based ink.

[0068] (3), on the transparent sheet that is printed with pattern ink pattern 2, coat ink full network...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com