Perfluorination carbon emulsion and preparing method thereof

A technology of perfluorocarbons and emulsions, which is applied in the fields of active ingredients of fluorine compounds, pharmaceutical formulations, and emulsion delivery, etc. It can solve problems such as sudden blood pressure, complement activation, and insufficient biocompatibility, and achieves small particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of its perfluorocarbon emulsion comprises the following steps:

[0035] (1) Dispersing a certain amount of phospholipids in water or a buffer containing a stabilizer and an osmotic pressure regulator to prepare a phospholipid dispersion.

[0036] (2) Mix perfluorodecalin (perfluorodecalin, PFD) and perfluoro-N-4-methylcyclohexylpiperidine (perfluoro-N-(4-methylcyclohexyl)-piperidine, PFMCP) in a certain volume ratio Preparation of fluorocarbon mixed liquid.

[0037] (3) Dispersing a certain amount of fluorocarbon mixture obtained in step (2) in the phospholipid dispersion obtained in step (1) to form colostrum.

[0038] (4) The colostrum obtained in the step (3) is homogenized or micro-jetted to form a stable emulsion under certain pressure conditions, and after completion, the emulsion is subpackaged and sterilized to obtain a perfluorocarbon emulsion;

[0039] Alternatively, the emulsion is mixed in proportion with a buffer containing a stabil...

Embodiment 1

[0052] prescription:

[0053] PFD60ml

[0054] PFMCP 40ml

[0056] Disodium hydrogen phosphate 0.284g

[0057] Sodium dihydrogen phosphate 0.24g

[0058] Glycerin 25g

[0059] Appropriate amount of water for injection

[0060] Full volume 1000ml

[0061] Method one:

[0062] The whole process was carried out under nitrogen protection.

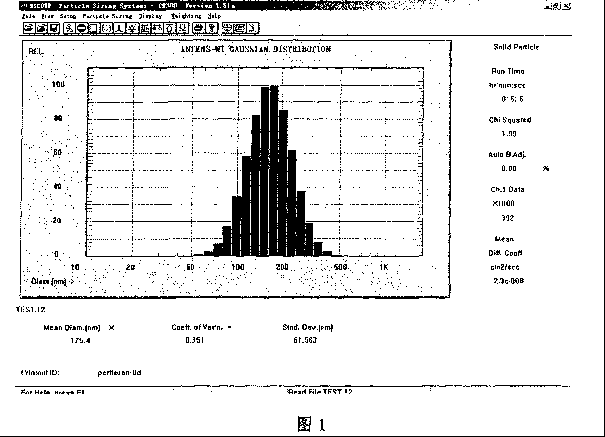

[0063] Take PFD and PFMCP, stir well, heat to 80°C±5°C, use as oil phase, and set aside. Take another appropriate amount of water for injection, heat to 80°C±5°C, add disodium hydrogen phosphate, sodium dihydrogen phosphate and glycerin, stir until dissolved, then add egg yolk lecithin, stir vigorously until evenly dispersed, slowly add the oil phase, add Stir for a while after finishing, then use a high-pressure homogenizer for homogenization, keep the homogenization temperature at 60°C±5°C, adjust the homogenization pressure and the number of homogenization, so that the average particle size is below 400nm, ...

Embodiment 2

[0069] prescription:

[0070] PFD 140ml

[0071] PFMCP 60ml

[0073] Disodium hydrogen phosphate 0.284g

[0074] Sodium dihydrogen phosphate 0.24g

[0075] Vitamin E 0.1g

[0077] Appropriate amount of water for injection

[0078] Full volume 1000ml

[0079] Method one:

[0080] The whole process was carried out under nitrogen protection.

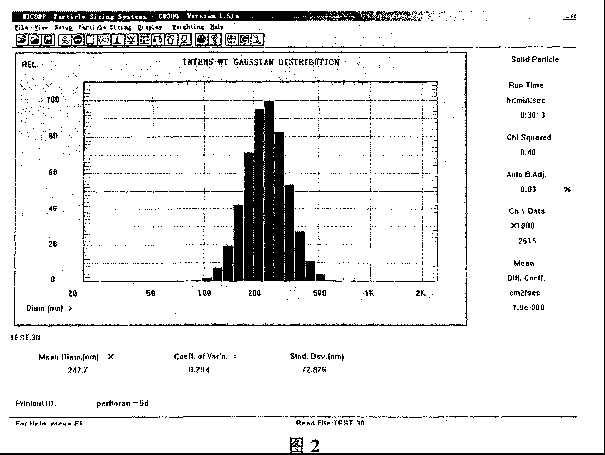

[0081] Take PFD and PFMCP, stir well, heat to 40°C±5°C, use as oil phase, and set aside. Take another appropriate amount of water for injection, heat to 40°C±5°C, add disodium hydrogen phosphate, sodium dihydrogen phosphate and sodium chloride, stir until dissolved, then add vitamin E and egg yolk lecithin, stir vigorously until dispersed evenly, slowly Add the oil phase, stir for a while after the addition, and then use a high-pressure homogenizer to homogenize, keep the homogenization temperature at 40°C±5°C, adjust the homogenization pressure and homogenization times...

PUM

| Property | Measurement | Unit |

|---|---|---|

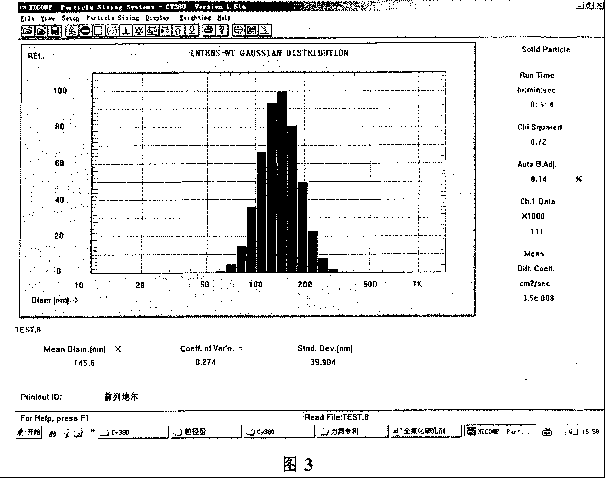

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com