Chemical processing-free negative graph photosensitive composition suitable for UV-CTP and planographic printing plate manufactured therefor and planographic printing plate manufacture method

A chemical-free, UV-CTP technology, applied in the photo-engraving process of the pattern surface, photosensitive materials for opto-mechanical equipment, optics, etc., can solve the problems of dirtying, contamination of printing machines, harmful and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

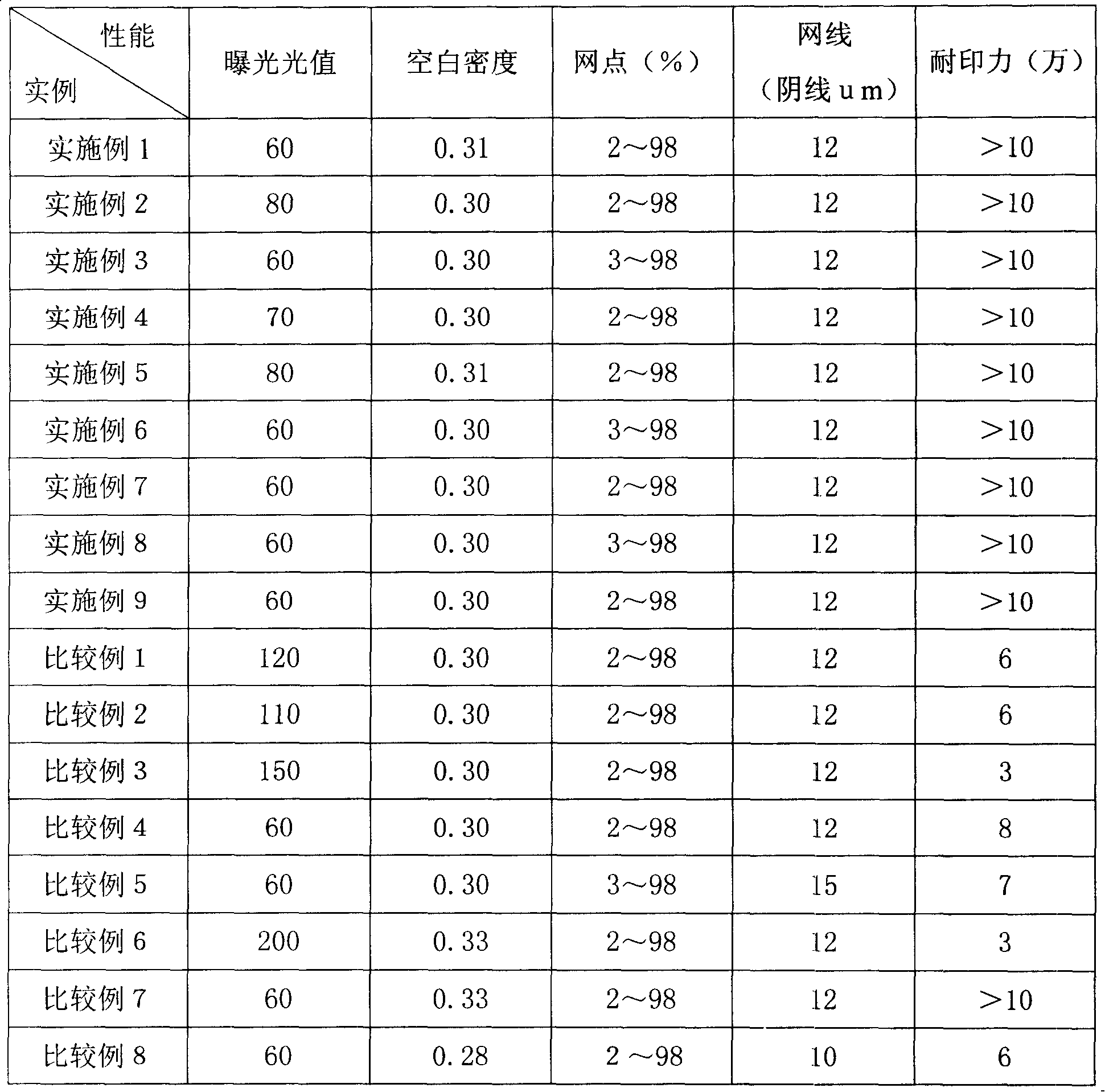

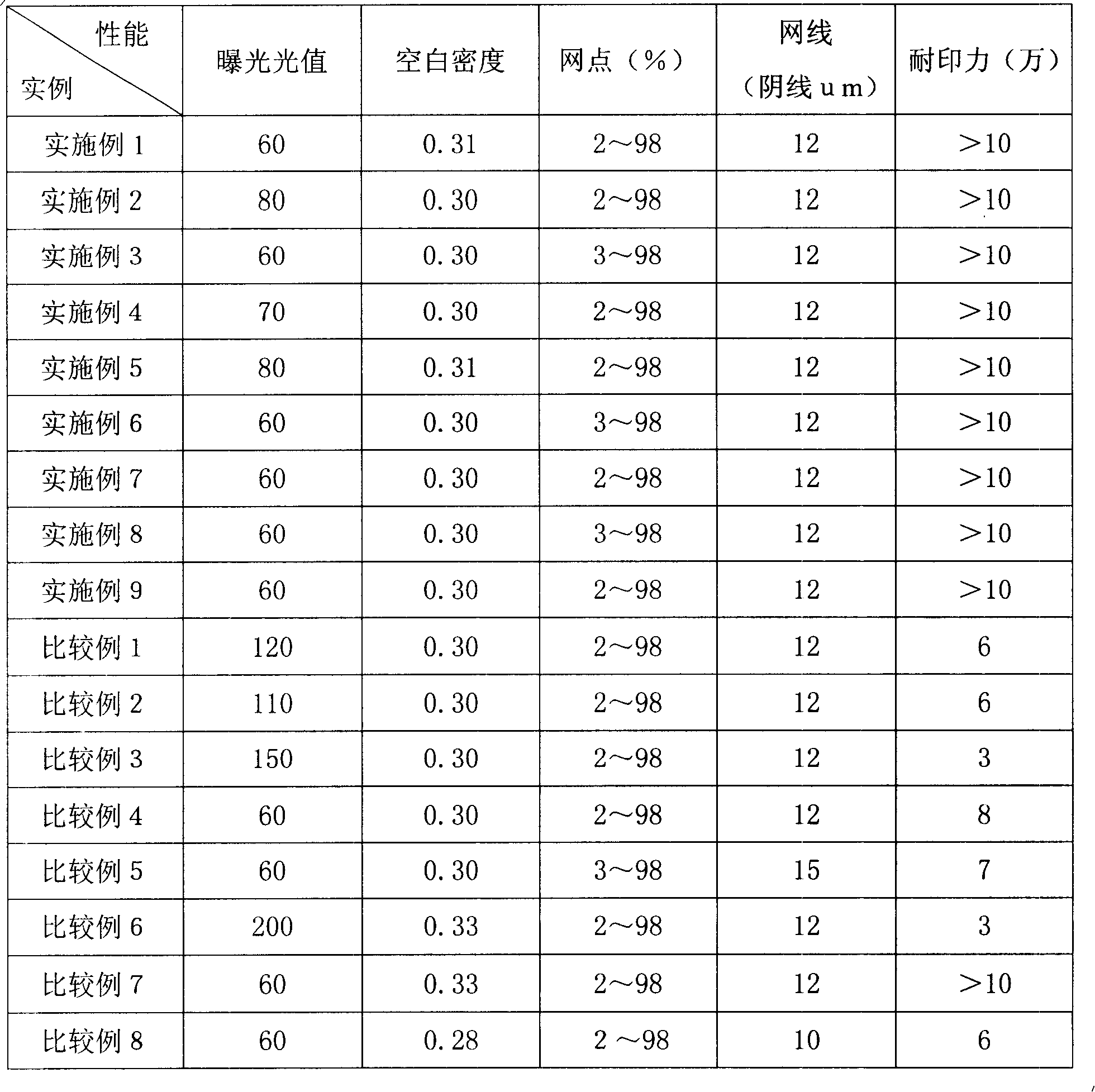

Examples

Embodiment 1

[0024] The chemical-free negative photosensitive composition suitable for UV-CTP of the present invention mainly includes the following six components: (1) an unsaturated water-soluble polymer of -(X)-(Y)-(Z)-structure , and (2) a photopolymerizable prepolymer, and (3) a polyfunctional monomer, and (4) one or more photopolymerization initiators, and (5) one or one More than one kind of dyes or pigments, and (6) one or more solvents; wherein, X represents a copolymerization unit containing a sulfonic acid group, and Y represents a branched carboxylic acid copolymerization unit containing two unsaturated double bonds , Z represents an acrylate copolymerized unit containing an unsaturated double bond branch.

[0025]X is selected from vinylsulfonic acid, styrenesulfonic acid, 2-hydroxyl-3-allyloxy-1-propylsulfonic acid, allyloxy Benzenesulfonic acid, 2-acrylamido-2-methylpropylsulfonic acid, isoprenesulfonic acid. X accounts for 10% molar ratio of the copolymer. Y is a branche...

Embodiment 2

[0031] The chemical-free negative photosensitive composition suitable for UV-CTP of the present invention mainly includes the following six components: (1) an unsaturated water-soluble polymer of -(X)-(Y)-(Z)-structure , and (2) a photopolymerizable prepolymer, and (3) a polyfunctional monomer, and (4) one or more photopolymerization initiators, and (5) one or one More than one kind of dyes or pigments, and (6) one or more solvents; wherein, X represents a copolymerization unit containing a sulfonic acid group, and Y represents a branched carboxylic acid copolymerization unit containing two unsaturated double bonds , Z represents an acrylate copolymerized unit containing an unsaturated double bond branch.

[0032] X is selected from vinylsulfonic acid, styrenesulfonic acid, 2-hydroxyl-3-allyloxy-1-propylsulfonic acid, allyloxy Benzenesulfonic acid, 2-acrylamido-2-methylpropylsulfonic acid, isoprenesulfonic acid. X accounts for 15% molar ratio of the copolymer. Y is a branch...

Embodiment 3

[0038] The chemical-free negative photosensitive composition suitable for UV-CTP of the present invention mainly includes the following six components: (1) an unsaturated water-soluble polymer of -(X)-(Y)-(Z)-structure , and (2) a photopolymerizable prepolymer, and (3) a polyfunctional monomer, and (4) one or more photopolymerization initiators, and (5) one or one More than one kind of dyes or pigments, and (6) one or more solvents; wherein, X represents a copolymerization unit containing a sulfonic acid group, and Y represents a branched carboxylic acid copolymerization unit containing two unsaturated double bonds , Z represents an acrylate copolymerized unit containing an unsaturated double bond branch.

[0039] X is selected from vinylsulfonic acid, styrenesulfonic acid, 2-hydroxyl-3-allyloxy-1-propylsulfonic acid, allyloxy Benzenesulfonic acid, 2-acrylamido-2-methylpropylsulfonic acid, isoprenesulfonic acid. X accounts for 20% molar ratio of the copolymer. Y is a branch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com