Laser cutting device

A technology of laser cutting and laser cutting head, which is applied in the direction of lasers, laser welding equipment, laser parts, etc., can solve the problems of complex optical path correction, high energy consumption, and high manufacturing cost, and achieve simple optical path correction, high cutting precision, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

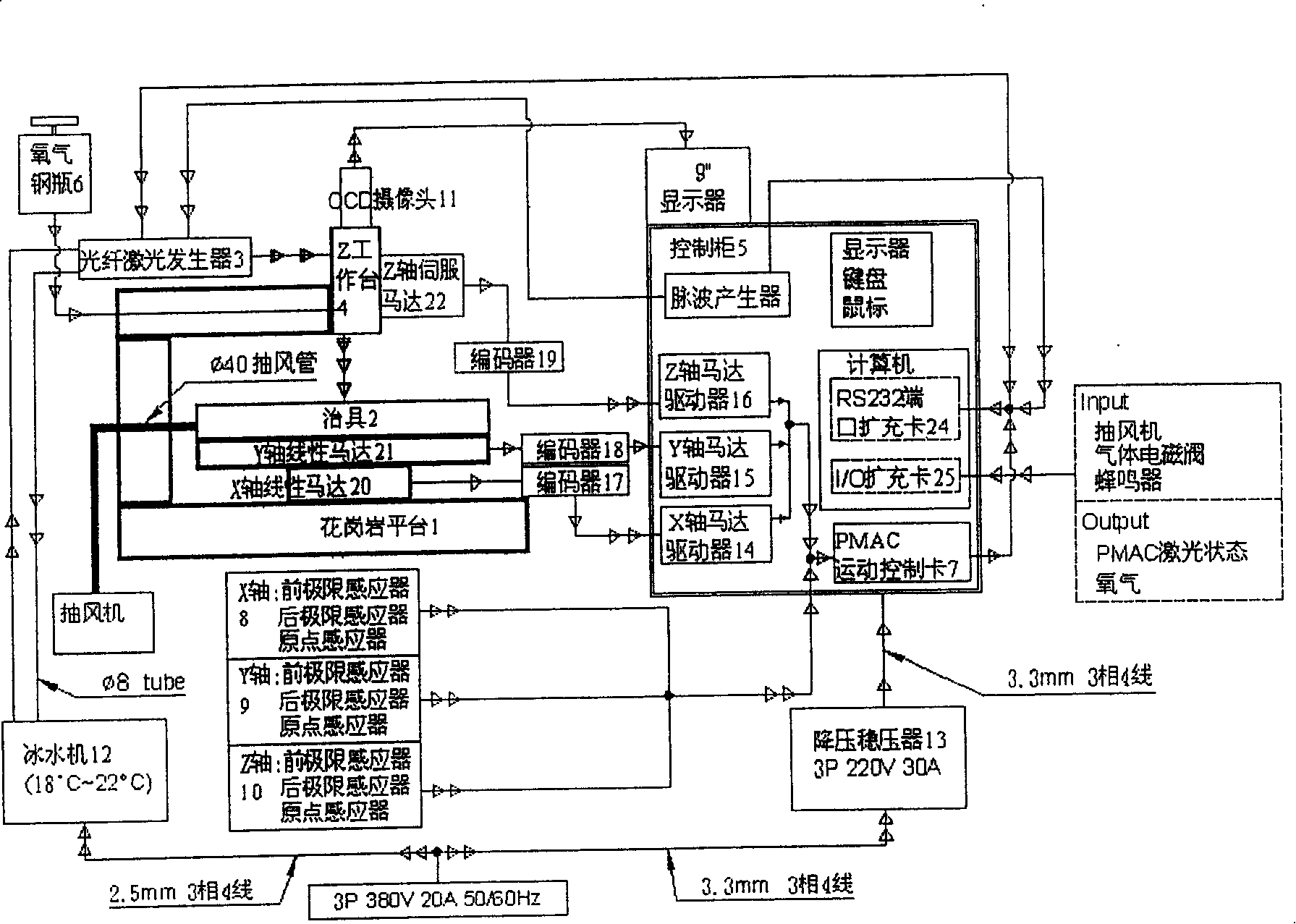

[0025] The laser cutting device for cutting steel plates as shown in the accompanying drawings includes a laser cutting head system, an X-Y table that can move in the horizontal direction and a granite platform 1 with a counterweight, and a jig 2 arranged on the X-Y table, The laser cutting head system includes a fiber laser generator 3, a Z worktable 4 that can move in the vertical direction, and also includes a motion control unit that is provided with an X-Y workbench and a Z workbench, a laser generator control unit and a system control unit. control cabinet5.

[0026] The X-Y workbench is a workbench that uses the slider to perform an infinite cycle of limited linear motion through the steel balls between them on the linear slide rail.

[0027] The laser cutting head system also includes a high-pressure oxygen nozzle located around the laser beam, and the oxygen flow from the oxygen cylinder 6 that is substantially coaxial with the laser beam is ejected from the cutting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com