Method for preparing polythiophene-metal oxide nano composite material

A nano-composite material and oxide technology, which is applied in the field of preparation of conductive polymer-nano-metal oxide composite materials, can solve the problems of easy aggregation and poor stability of metal oxide nanoparticles, and achieve simple preparation process and mild reaction conditions , The effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

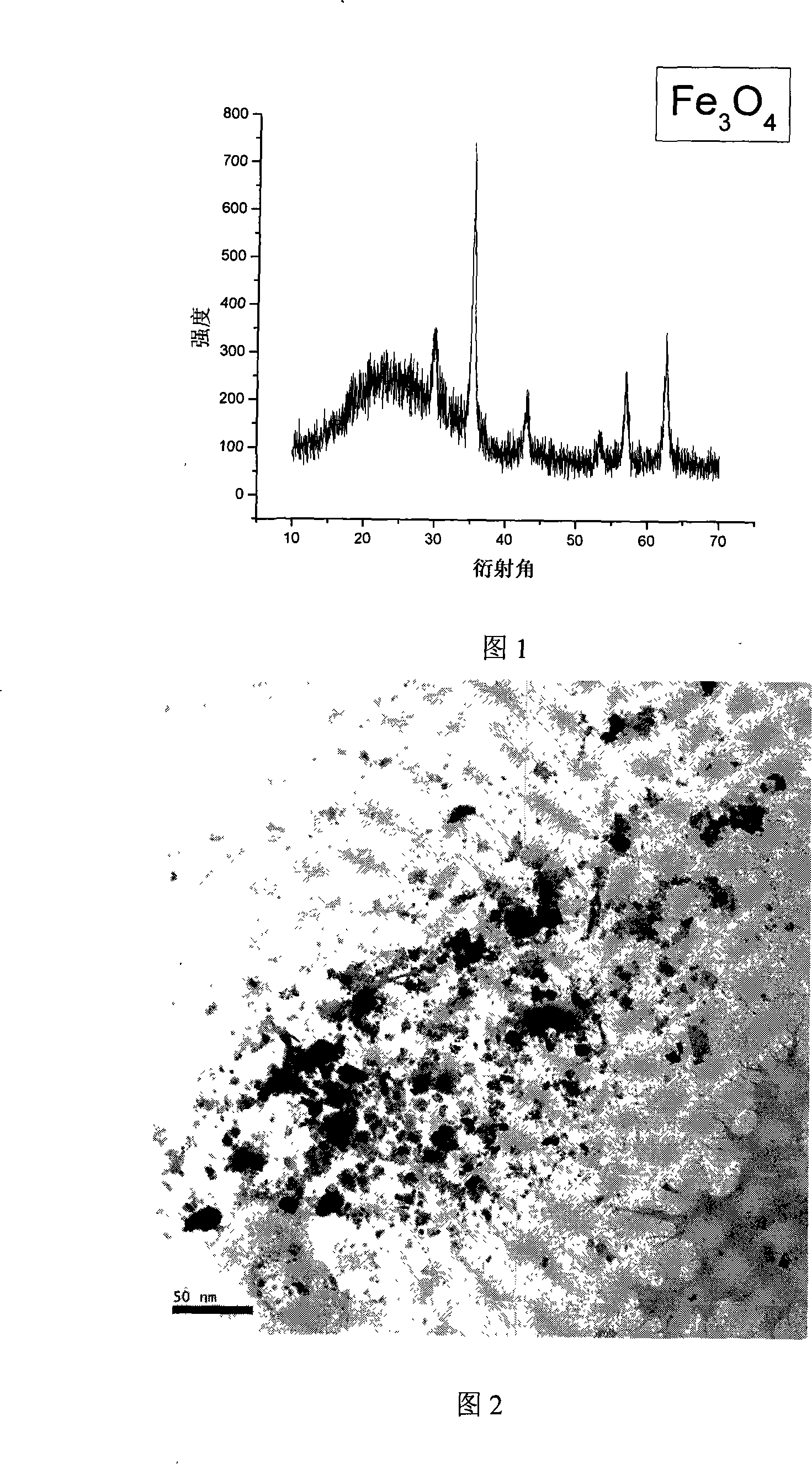

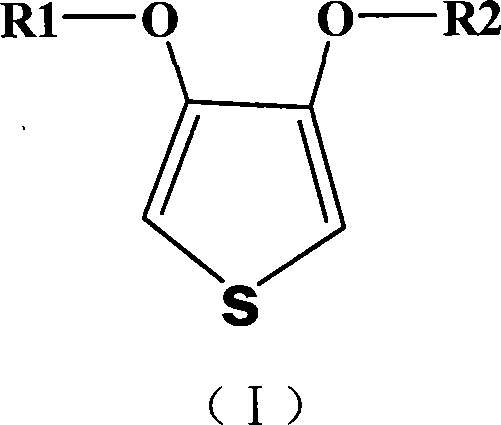

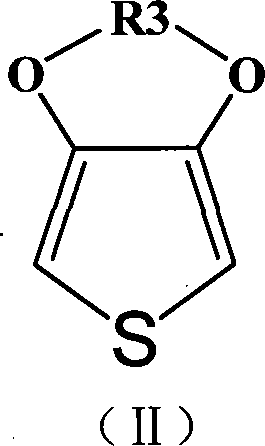

Embodiment 1

[0035] 0.4320g FeCl 3 ·6H 2 O and 0.2224 g FeSO 4 ·7H 2 O(Fe 3+ : Fe 2+=2:1) was dissolved in 150 ml of deionized water, and nitrogen gas was passed through for 5 minutes. Add dilute ammonia water under the condition of rapid stirring at room temperature, the color of the solution changes, stop dripping ammonia water when the solution turns completely black. Stirring was continued for 1 hour after the dropwise addition was complete. The obtained solution was centrifuged (5000 rpm, 5 minutes), and the precipitate obtained was washed 3 times with deionized water, and the precipitate was dispersed in deionized water to form a 250ml solution. Add 12.5 g of sodium polystyrene sulfonate solution (20% concentration) to the above solution, and stir at high speed for 4 hours. Add 1g of EDOT monomer, 2.26g of ammonium persulfate, 0.025g of ferric sulfate under stirring, drop in hydrochloric acid to adjust the pH value to 2-3, and stir at high speed for 24 hours. The mixed solu...

Embodiment 2

[0037] 0.9180g FeCl 3 ·6H 2 O and 0.4726g FeSO 4 ·7H 2 O(Fe 3+ : Fe 2+ =2:1) was dissolved in 150 ml of deionized water, and nitrogen gas was passed through for 5 minutes. Add dilute ammonia water under the condition of rapid stirring at room temperature, the color of the solution changes, stop dripping ammonia water when the solution turns completely black. Stirring was continued for 1 hour after the dropwise addition was complete. The obtained solution was centrifuged (5000 rpm, 5 minutes), and the precipitate obtained was washed 3 times with deionized water, and the precipitate was dispersed in deionized water to form a 250ml solution. Add 12.5 g of sodium polystyrene sulfonate solution (20% concentration) to the above solution, and stir at high speed for 4 hours. Add 1g of EDOT monomer, 2.26g of ammonium persulfate, 0.025g of ferric sulfate under stirring, drop in hydrochloric acid to adjust the pH value to 2-3, and stir at high speed for 24 hours. The mixed solu...

Embodiment 3

[0039] 2.0358g FeCl 3 ·6H 2 O and 1.0481g FeSO 4 ·7H 2 O(Fe 3+ : Fe 2+ =2:1) was dissolved in 150 ml of deionized water, and nitrogen gas was passed through for 5 minutes. Add dilute ammonia water under the condition of rapid stirring at room temperature, the color of the solution changes, stop dripping ammonia water when the solution turns completely black. Stirring was continued for 1 hour after the dropwise addition was complete. The obtained solution was centrifuged (5000 rpm, 5 minutes), and the precipitate obtained was washed 3 times with deionized water, and the precipitate was dispersed in deionized water to form a 250ml solution. Add 12.5 g of sodium polystyrene sulfonate solution (20% concentration) to the above solution, and stir at high speed for 4 hours. Then add 1g of EDOT monomer, 2.26g of ammonium persulfate, 0.025g of ferric sulfate under stirring, drop in hydrochloric acid to adjust the pH value to 2-3, and stir at high speed for 24 hours. The mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com