Oil field extracted water deoiling process by using supercritical liquid extraction technique

A technology of supercritical fluid and extraction technology, applied in the direction of extraction water/sewage treatment, etc., can solve the problems of longer time, long residence time, poor adaptability, etc., and achieve the effect of reducing treatment cost, prolonging use time, and proper critical temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

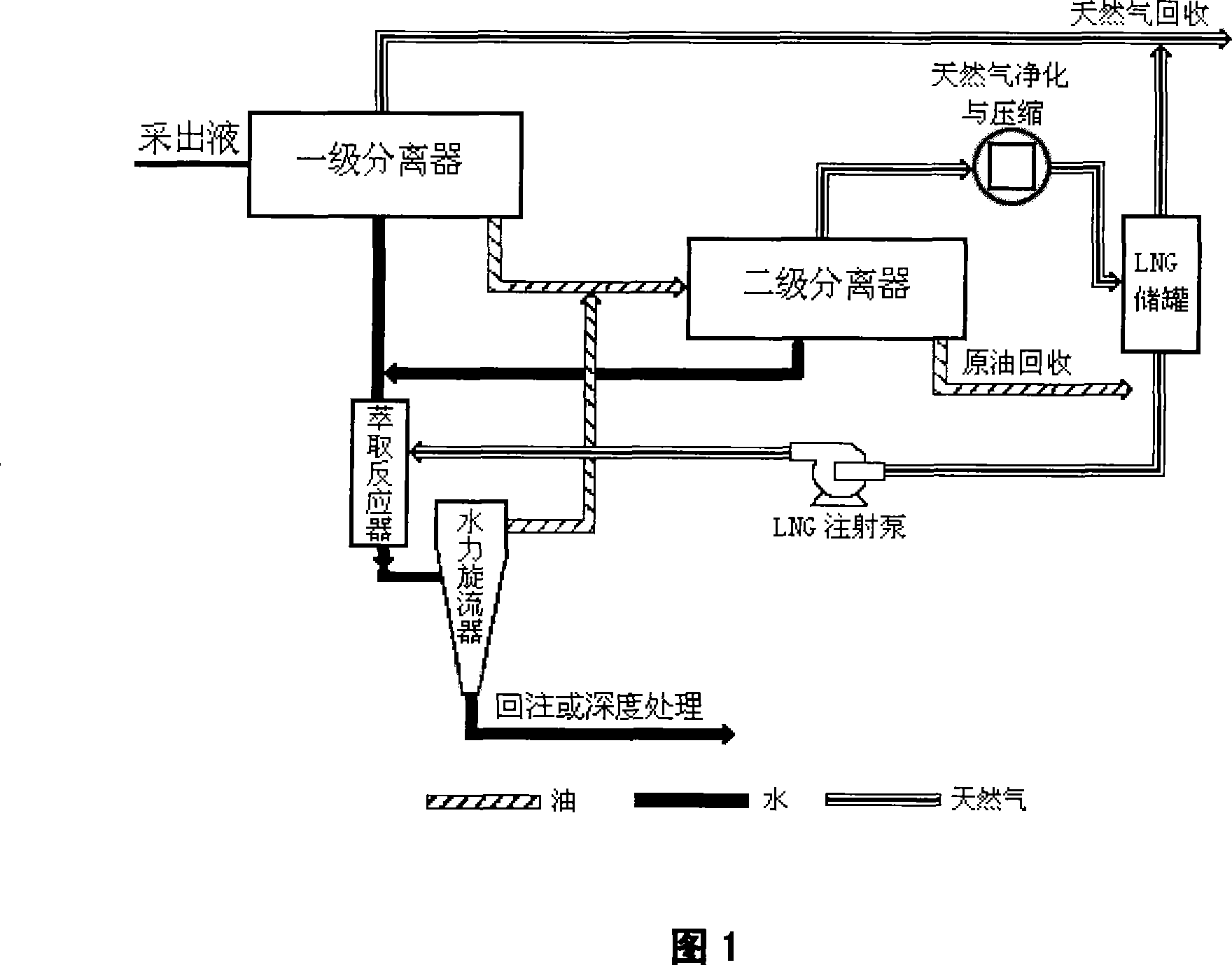

[0029] Embodiment 1 The deoiling of common produced water

[0030] The produced water of an oilfield (after settling and separation in a large tank) contains 216mg / L of oil in the raw water, and the density of crude oil is 0.8590g / cm3. After being directly deoiled by the hydrocyclone, the oil in the outlet is about 30-50mg / L. Adopt the process of the present invention, the LNG addition amount is 1.5%, after the technological process of Fig. 1 is processed, the hydrocyclone effluent oil content is less than 15mg / L; If adopt two-stage hydrocyclone process (Fig. 2), the LNG addition amount is 1.0% , the oil content of the final effluent can be reduced to below 5mg / L.

Embodiment 2

[0031] Example Dimer Flooding Produced Water Removal of Oil

[0032] The quality of the raw water produced by polymer flooding in an oilfield is: oil content 1800mg / L, polymer content 680mg / L, crude oil density 0.8920g / cm3, after direct oil removal by hydrocyclone, the outlet oil content is about 140-250mg / L.

[0033] Using the process shown in Figure 1, the amount of LNG added is 2.5%, and the oil content in the hydrocyclone effluent is about 50mg / L; The oil content can be reduced to below 15-30mg / L, and after fine filtration (walnut shell and fiber ball), the final oil content of the effluent can be reduced to below 5mg / L.

Embodiment 3

[0034] Example 3 Deoiling of Heavy Oil Produced Water

[0035] The raw water quality of heavy oil produced in an oilfield is (after demulsification and settlement): oil content 1100mg / L, crude oil density 0.9770g / cm3, the oil content after direct oil removal by hydrocyclone is about 120-180mg / L, oil removal less efficient.

[0036] Using the process shown in Figure 1, the amount of LNG added is 2.5%, and the oil content in the effluent of the hydrocyclone can be reduced to about 20-40mg / L; The oil content of the hydrocyclone effluent can be reduced to below 10mg / L, and after fine filtration (walnut shells and fiber balls), the final oil content of the effluent can be reduced to below 2mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com