Molten steel component monitoring and analytical equipment

An analysis device and liquid steel technology, applied in the direction of material excitation analysis, etc., can solve problems such as not being able to satisfy dynamic control, and achieve the effects of convenient installation, small size and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

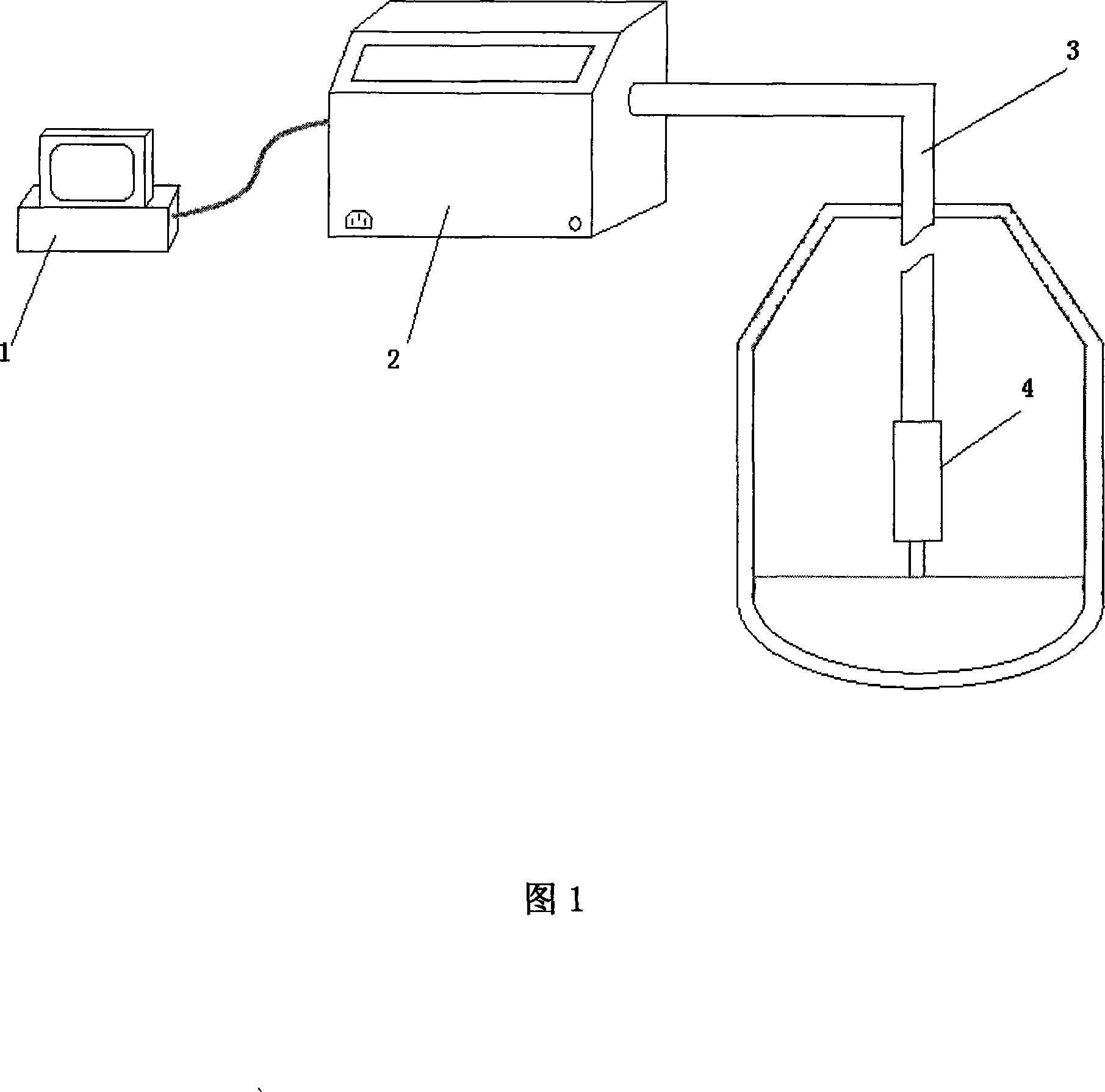

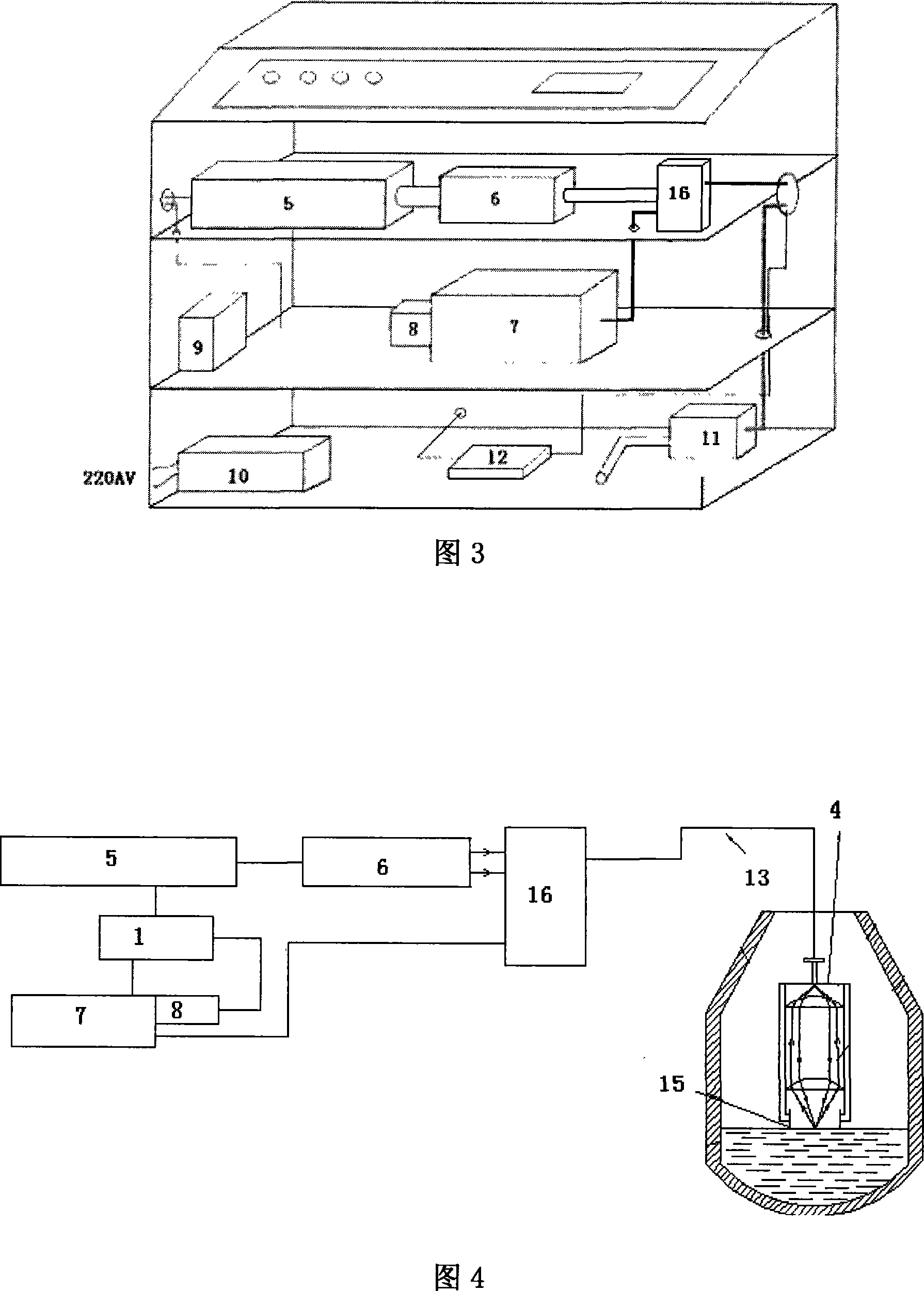

[0029] As shown in FIG. 1 , the present invention includes four components: a detection probe 4 , a telescopic tube 3 , a signal generating and collecting part 2 and a processor 1 .

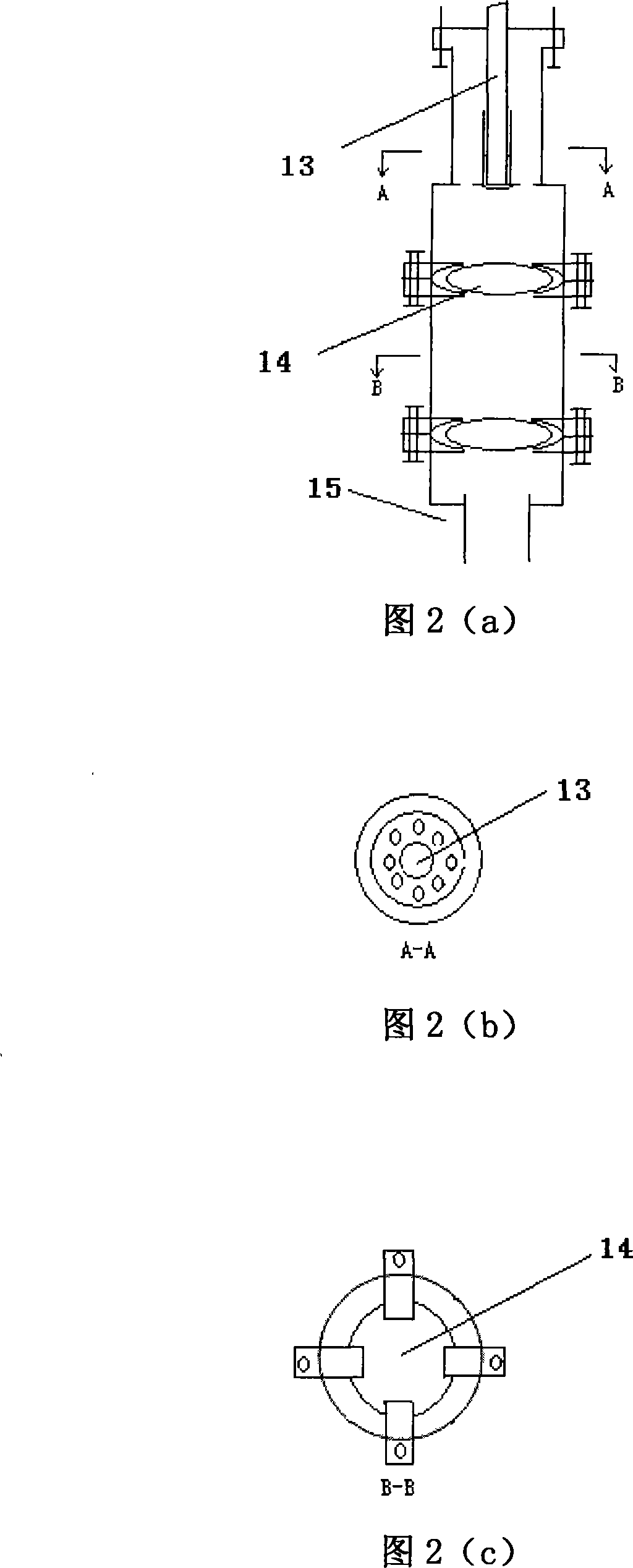

[0030] The detection probe 4, whose specific structure is shown in Figure 2(a), Figure 2(b), and Figure 2(c), is equipped with a high-temperature-resistant focusing lens suspended inside a high-temperature-resistant metal cylinder with a diameter of 8 cm and a length of 30 cm. 14. Align the position of the focusing lens 14 to install the conductive optical fiber 13, and spray high-reflective and high-temperature-resistant paint on the outside of the metal cylinder to adapt to the high-temperature detection environment. The high-temperature-resistant focusing lens 14 is used for focusing the laser beam, and passes through a cold inert gas flow for purging and cooling. The front end of the probe is equipped with two electrodes 15 with a length of 15 cm, which are used for automatic detection of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com