Aluminium alloy material for louvre window and manufacturing method therefor

A manufacturing method and aluminum alloy technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems affecting market share and popularization, high parameters such as rolling force, difficult to control rolling force, etc. Achieve significant economic and social benefits, stable product performance, and reduce production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

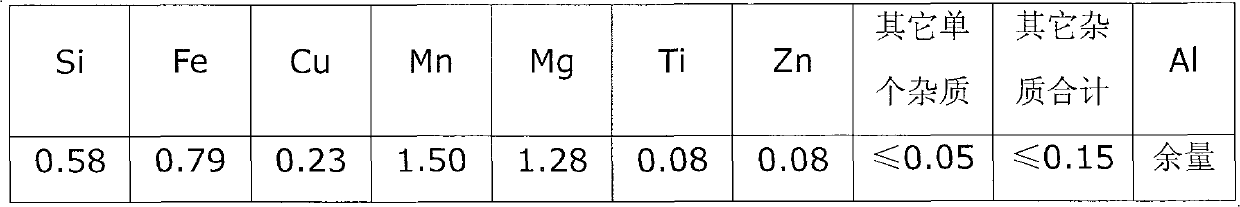

[0053] Chemical Composition of Materials (WT%): Table 3

[0054]

[0055] (1) Calculate and prepare the materials according to the above ingredients, put them into the melting furnace for melting, the input ratio of recycled aluminum is 100%, the melting temperature is controlled at 750°C, after refining, slag removal, stirring, analyzing and adjusting the ingredients, enter the static furnace, Standing, refining, degassing, slag removal, adding Al-5Ti-1B wire into the molten aluminum and then entering the casting machine to cast into ingots, the casting temperature is controlled at 710°C;

[0056] (2) The thickness of the ingot is 450mm, and the large and small faces of the ingot are soaked after milling, and the homogenized holding temperature and time: 565°C*13h;

[0057] (3) The start-rolling temperature of hot rolling is controlled at 515°C, the finish rolling temperature is controlled at 255°C, the rolling passes are 25 passes, and the thickness of the hot-rolled bill...

Embodiment 2

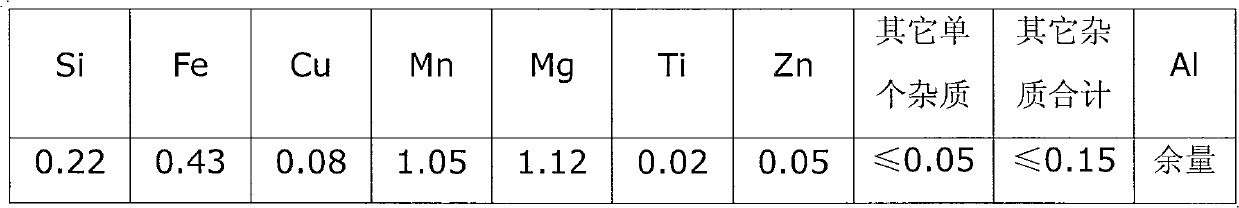

[0062] Chemical Composition of Materials (WT%): Table 4

[0063]

[0064] (1) Calculate and prepare the materials according to the above ingredients, put them into the melting furnace for melting, the melting temperature is controlled at 740 ° C, after refining, slag removal, stirring, analysis and adjustment of ingredients, enter the static furnace, stand still, refine, degas , Slag removal, adding Al-5Ti-1B wire into the molten aluminum and casting it into a casting machine to form an ingot, and the casting temperature is controlled at 700°C;

[0065] (2) The thickness of the ingot is 450mm, the temperature and time of homogenization and holding time: 575°C*11h, after soaking, mill the large and small faces of the ingot;

[0066] (3) The starting temperature of hot rolling is controlled at 520°C, the final rolling temperature is controlled at 310°C, the rolling passes are 23 passes, and the thickness of the hot-rolled billet is 7.0mm;

[0067] (4) The hot-rolled billet i...

Embodiment 3

[0071] Chemical composition (WT%) of the material: Table 5

[0072]

[0073] (1) Calculate and prepare recycled materials according to the above ingredients, put them into the melting furnace for melting, the proportion of waste materials is 50%, and the melting temperature is controlled at 730°C. Placement, refining, degassing, slag removal, adding Al-5Ti-1B wire into the molten aluminum and then entering the casting machine to cast into ingots, the casting temperature is controlled at 690 °C;

[0074] (2) The thickness of the ingot is 450mm, and the large and small faces of the ingot are soaked after milling, and the homogenized holding temperature and time: 580°C*9h;

[0075] (3) The starting temperature of hot rolling is controlled at 530°C, the final rolling temperature is controlled at 278°C, the rolling pass is 25 passes, and the thickness of the hot-rolled billet is 6.0mm;

[0076] (4) The hot-rolled billet is rolled to a semi-finished product with a thickness of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com