Highly visible arc protective multilayer composite fabric

A multi-layer composite and anti-arc technology, applied in protective clothing, protective equipment, layered products, etc., can solve the problems of insufficient fluorescence, failure to meet the requirements of fluorescent color, and low peeling strength, etc., to improve air permeability Wet performance, improve the effect of heat insulation protection, improve the effect of anti-arc index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

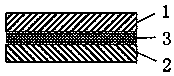

[0041] A high-visibility anti-arc multilayer composite fabric can be used in the field of anti-arc, such as figure 1As shown, it includes: a surface fabric 1 and an inner fabric 2, and the surface fabric 1 and the inner fabric 2 are bonded by a flame-retardant glue 3; the surface fabric 1 is made of acrylic and Lenzing flame-retardant viscose Yarn blended; the inner fabric 2 is made of silicon nitrogen flame-retardant viscose, para-aramid, sulfonamide and polyimide yarn blended; the flame-retardant glue is flame-retardant polyurethane or Flame retardant EVA.

[0042] The specific processing technology is as follows:

[0043] 1) Selection of raw materials: Calculated by mass percentage, the yarn of the surface fabric 1 is 60% acrylic and 40% flame-retardant viscose blended yarn; the yarn of the inner fabric 2 is 50% polysulfone, 35% silicon nitrogen flame retardant viscose, 10% polyimide, 5% para-aramid blended yarn.

[0044] 2) Yarn: The raw materials are fully mixed, the t...

Embodiment 2

[0050] A high-visibility arc-proof multi-layer composite fabric, which can be used in the field of arc protection, such as figure 2 As shown, from top to bottom, it includes: surface fabric 1, flame retardant glue 3, functional film 4, flame retardant glue 3 and inner fabric 2, and the surface fabric 1 and the functional film 4 pass through the flame retardant The flame-retardant glue 3 is bonded, and the functional film 4 and the inner fabric 2 are bonded by the flame-retardant glue 3; the surface fabric 1 is made of acrylic, Lenzing flame-retardant viscose and flame-retardant cotton yarn blended fabric The inner fabric 2 is made of silicon nitrogen flame-retardant viscose, para-aramid and sulfonamide yarn blended; the flame-retardant glue is flame-retardant polyurethane or flame-retardant EVA; the functional film 4 is a flame-retardant PU film with waterproof and moisture-permeable functions.

[0051] The specific processing technology is as follows:

[0052] 1) Selection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com