Immobilized fibrous bed bioreactor for fermentation productions of ethylformic acid, butyric acid and succinic acid

A reactor and fiber bed technology, which is used in the fermentation production of succinic acid, propionic acid, butyric acid, and immobilized fiber bed reactors, can solve the problem that cells are difficult to achieve self-renewal, not suitable for large-scale production of propionic acid, and unsuitable for large-scale production of propionic acid. Live cell fermentation and other problems, to achieve the effect of strong adaptability and organic acid production capacity, low cost, and simplified equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

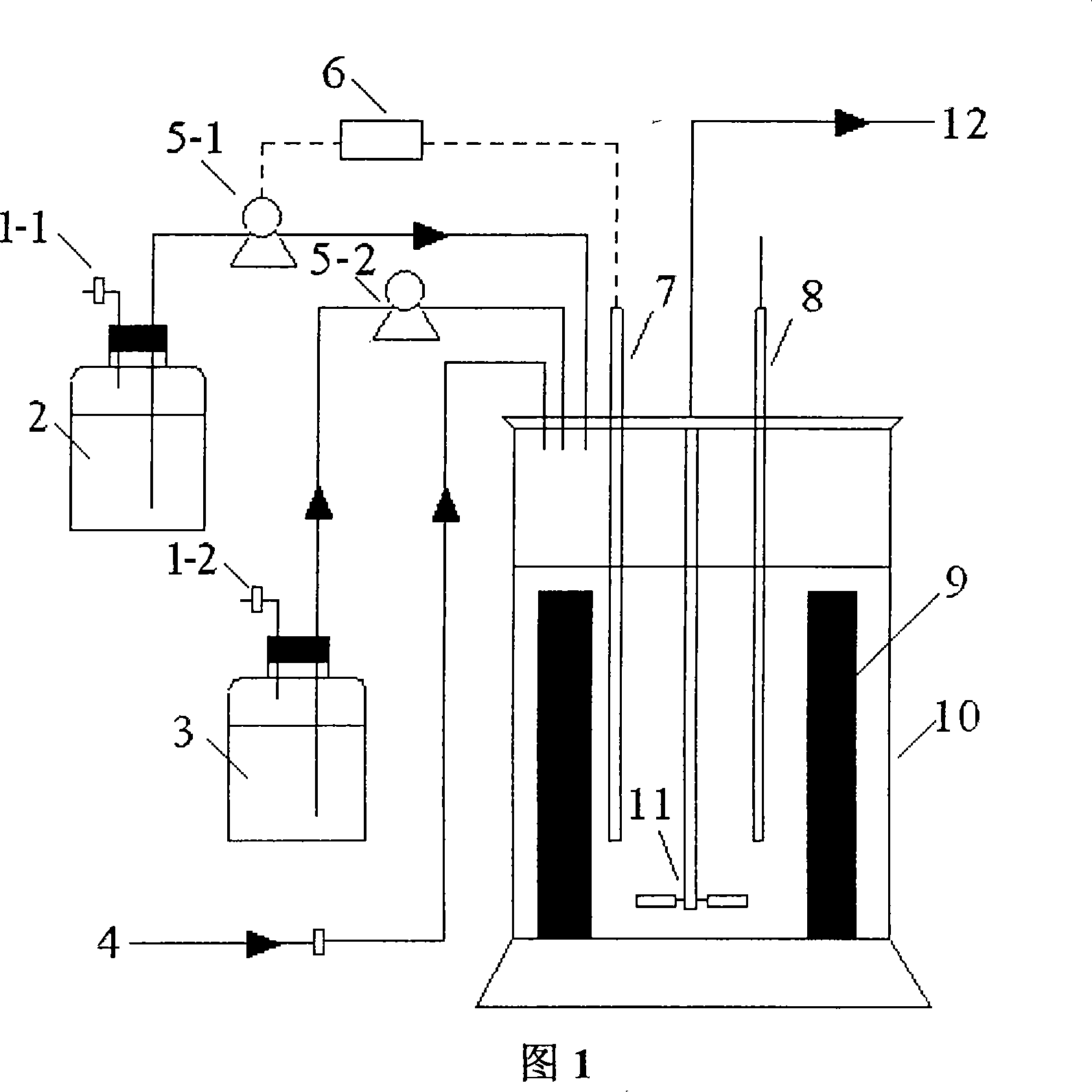

[0033] Embodiment 1 The method for producing propionic acid

[0034] Propionibacterium freudeenreichii NX-4 (Propionibacterium freudeenreichii NX-4, patent application number: 200710020579.8) which has been patented by our laboratory is used to produce propionic acid in an immobilized fiber bed reactor. Seed medium: glucose 20g / l, peptone 5g / l, yeast extract 5g / l, NaCl 5g / l, pH 6.9. Fermentation medium: corn steep liquor 40g / l, (NH 4 ) 2 SO 4 2g / l, K 2 HPO 4 5g / l, NaCl 1g / l, pH 6.9.

[0035] The plant fiber (gauze) 9 is fixed in the reactor 10, and the P. freundii NX-4 seed solution is inserted into the reactor 10 pre-loaded with 3L seed culture medium at an inoculum size of 5% (v / v). , temperature 35°C, feed 0.1L / min N from inert gas inlet 4 2 , using the stirring device 11 to stir (rotating speed 200r / min), while using the constant flow pump 5-1 to fill the 8mol / l sodium hydroxide solution in the lye bottle 2 into the reactor 10 to control the pH 6.0, and cultivate ...

Embodiment 2

[0036] Embodiment 2 The method for producing propionic acid

[0037] Production of propionic acid in an immobilized fiber bed reactor using Propionibacterium fresnerei NX-4. Seed medium and fermentation medium are the same as in Example 1. The animal fiber (wool fabric) 9 is fixed in the reactor 10, and the P. freundii NX-4 seed solution is inserted into the reactor 10 pre-loaded with 3L seed medium by the inoculation amount of 15% (v / v). , feed 0.1L / min N from the inert gas inlet 4 2 , using the stirring device 11 to stir (rotating speed 300r / min), while using the constant flow pump 5-1 to add 3mol / l sodium hydroxide solution to control the pH 6.0, and culture for 48h to realize the immobilization of the cells on the fiber 9. Replace the seed solution in the reactor 10 with the fermentation medium (initial glucose concentration 120g / l), the initial pH is 6.9, use the constant flow pump 5-1 to add 3mol / l sodium hydroxide solution to control the pH 6.0, and the temperature is...

Embodiment 3

[0038] Embodiment 3 The method for producing propionic acid

[0039] Production of propionic acid in an immobilized fiber bed reactor using Propionibacterium fresnerei NX-4. Seed medium and fermentation medium are the same as in Example 1. Synthetic fiber (polyester fabric) 9 is fixed in the reactor 10, by the inoculum size of 10% (v / v) the reactor 10 that Propionibacterium frescherii NX-4 seed solution is inserted in advance and is equipped with 3L seed culture medium , feed 0.1L / min N from the inert gas inlet 4 2 , use the stirring device 11 to stir (speed 600r / min), and use the constant flow pump 5-1 to add 6mol / l sodium bicarbonate solution to the reactor 10 to control the pH 6.0 and cultivate for 40h to realize the immobilization of the cells on the fiber 9 . The seed liquid in the reactor 10 is replaced with fermentation medium (initial glucose concentration), and initial pH is 6.9, utilizes constant flow pump 5-1 to add 6mol / l sodium bicarbonate solution to control p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com