Method for preparing novel welfless cloth and composite UD profile

A new technology without weft fabric, applied in the field of polymer composite material preparation, can solve problems such as uneven glue layer, polluting workshop environment, affecting product performance, etc., to ensure overall uniformity, ensure workshop environment, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

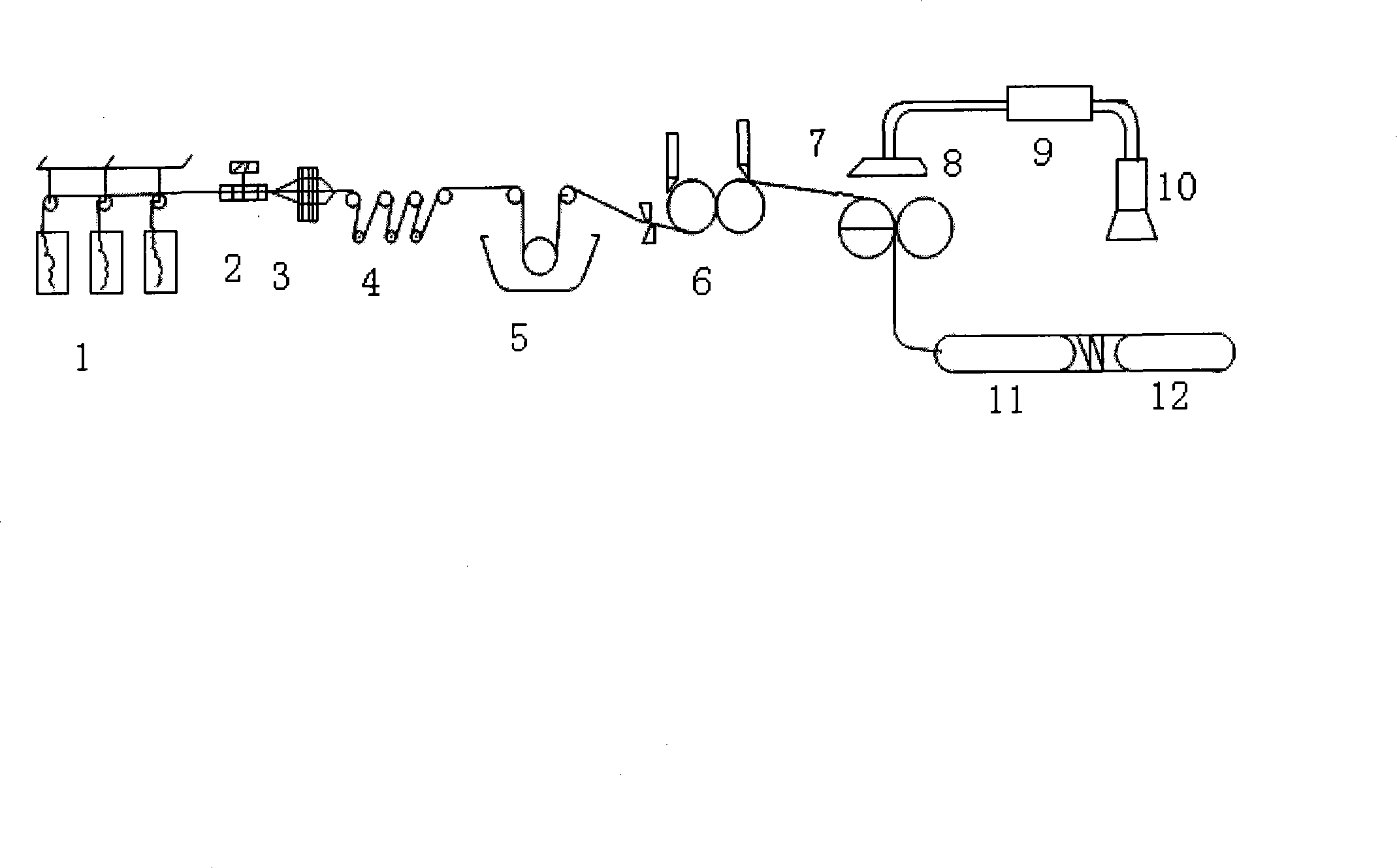

Image

Examples

Embodiment 1

[0026] The raw material is high-strength high-modulus polyethylene fiber, the specification is 1000D / 240f, and the number of cluster tubes is 60. Adhesive is sodium butadiene glue (commercially available); glue concentration is 20%, spray pressure is 0.18Kg / cm 2 ; Laying speed is 30m / min, parallel composite layer is 60 layers; fiber / adhesive weight ratio is 80 / 20. Measured UD profile V 50 =589m / s.

Embodiment 2

[0028] The raw material is aramid fiber, the specification is 800D / 200f, the number of cluster tubes is 40, the adhesive is styrene-butadiene rubber (commercially available); the dipping concentration is 30%, and the spray pressure is 0.18Kg / cm 2 ; Laying speed is 30m / min, parallel composite: 60 layers, fiber / adhesive weight ratio is 80 / 20. Measured UD profile V 50 = 550m / s.

Embodiment 3

[0030] The raw material is polyacrylonitrile-based carbon fiber, 600D / 100f, the number of cluster tubes is 30, the adhesive is thermoplastic PVA (commercially available); the sol concentration is 25%, and the spray pressure is 0.18Kg / cm 2 ; Laying speed is 30m / min, parallel composite layer is 60 layers, fiber / adhesive weight ratio is 80 / 20. Measured UD profile V 50 =538m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com