Method for preventing cast steel stove continuous casting water gap from obstruction and reducing erosion

A continuous casting nozzle and anti-clogging technology, which is applied to casting equipment, casting molten material containers, metal processing equipment, etc., can solve the problems of inability to prevent nozzle clogging, billet defects, and limited CaO composition, and achieve improved anti-clogging and Reduce erosion, improve effect, power supply and convenient operation on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3, Embodiment 5

[0064] A continuous casting nozzle of a steel casting furnace is used, and the composition of pouring molten steel is: C 0.0030-0.35%, Si 0.01-0.45%, Mn 0.2-1.2%, P 0.006-0.02%, S 0.001-0.030%. The cast slabs are slabs, round billets and thin slabs.

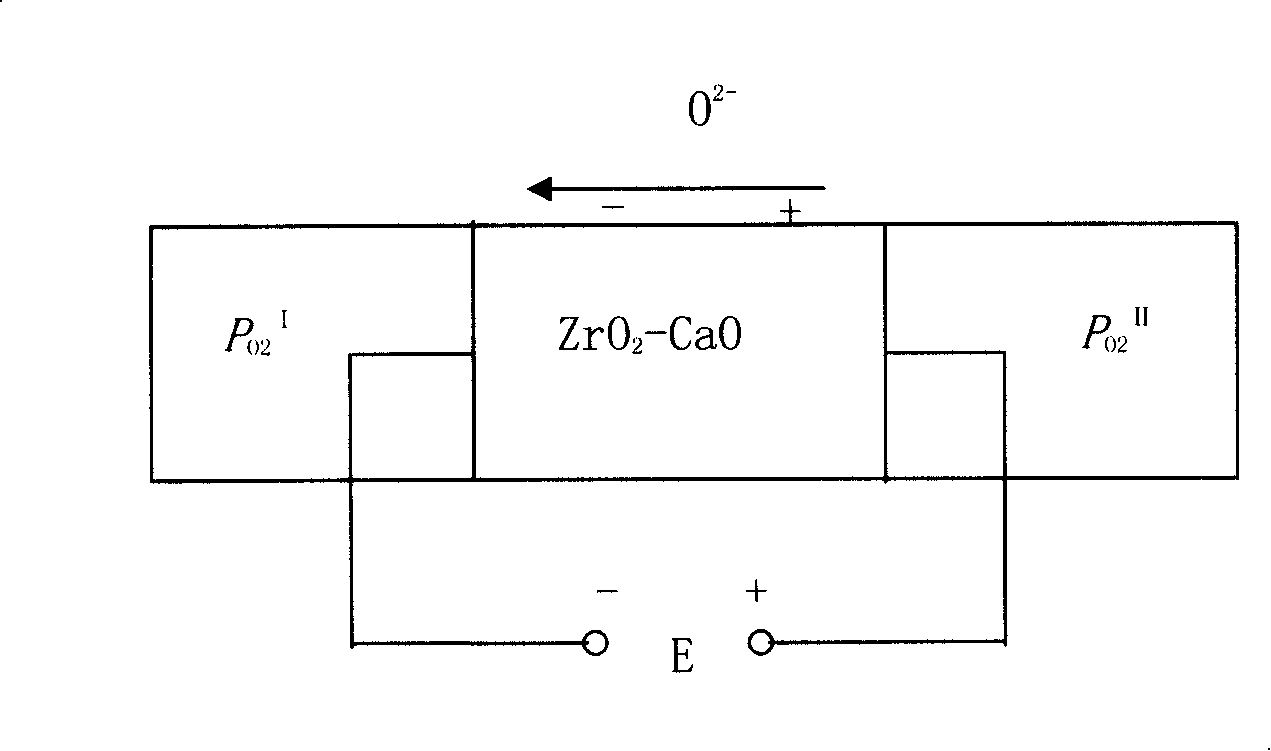

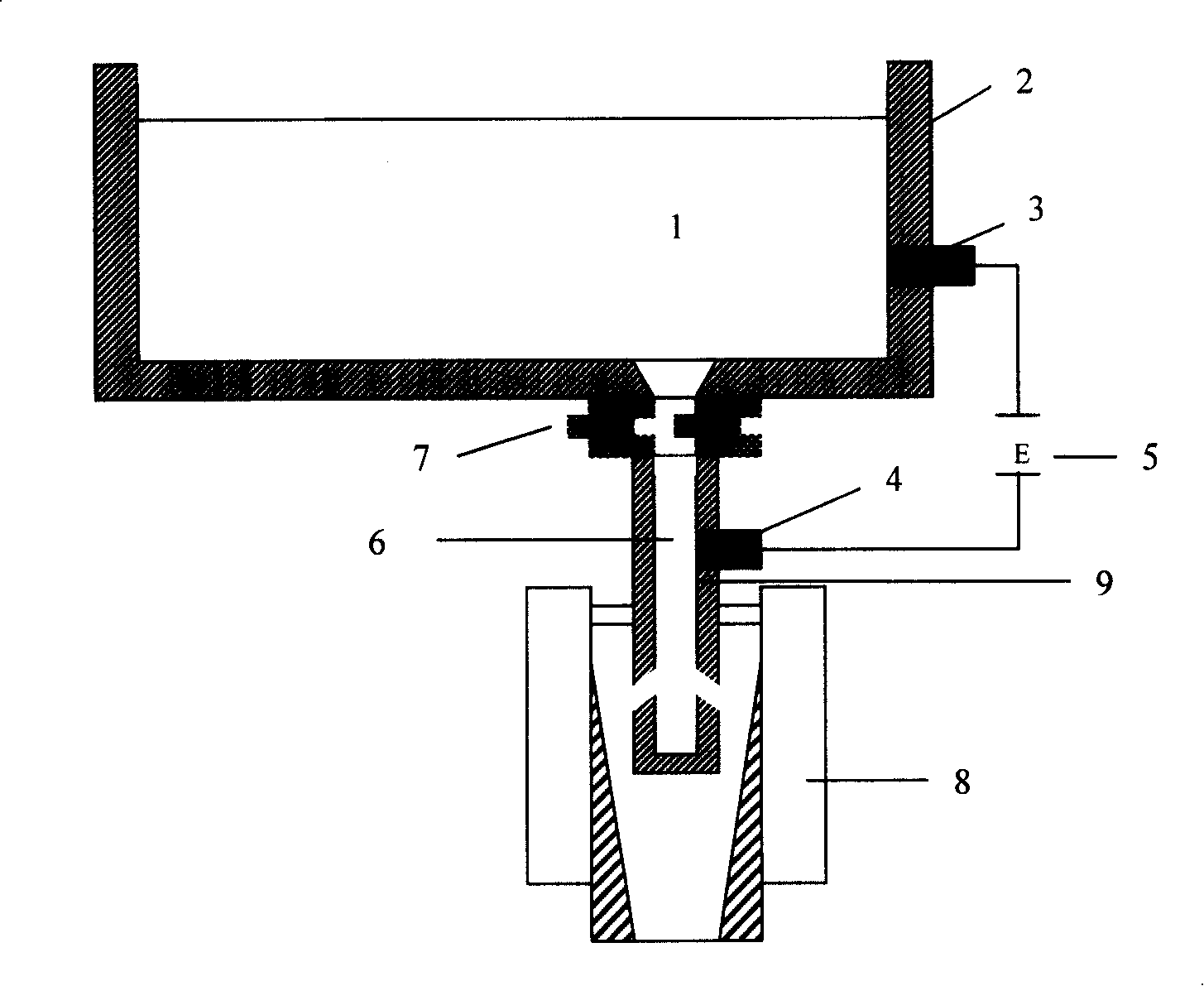

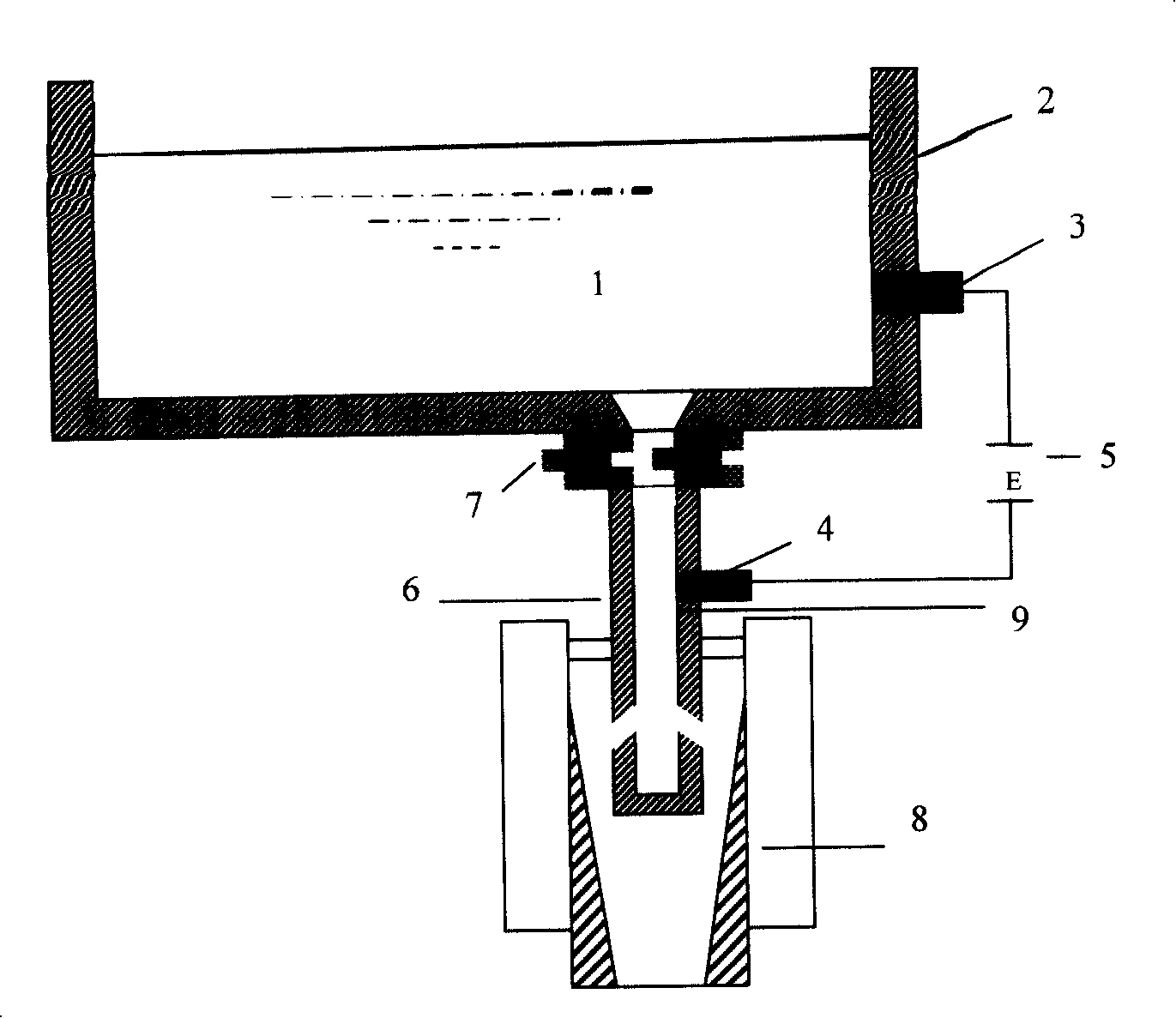

[0065] Such as Figure 1-2 As shown, the inner wall of the continuous casting nozzle of the casting furnace is used as one pole, and the molten steel is used as the other pole. By changing the polarity of the electric field and the magnitude of the current on the inner wall of the nozzle, the adhesion speed of oxides in the molten steel on the inner wall of the nozzle is controlled.

[0066] The inner wall lining of the tundish is made of MgO or MgO-CaO paint, and the inner wall lining of the continuous casting nozzle is made of conductive refractory material. The inner wall lining of the continuous casting nozzle is Al 2 o 3 - C quality and inner layer lined with ZrO 2 Al 2 o 3 -ZrO 2 -C quality refractory material, slidi...

Embodiment 4

[0071] Except that this embodiment is an embodiment after changing the positive and negative poles of the electric field, that is, the nozzle (inner wall) is connected to the negative pole of the power supply, and the molten steel is connected to the positive pole, the others are the same as Embodiments 1-3 and Embodiment 5. casting operation.

[0072] Under the action of the electric field, the oxygen position at the contact interface between the nozzle and the molten steel decreases, thereby reducing the oxidation and adhesion of acid-soluble aluminum on the surface of the nozzle (inner wall). In addition, due to the electrochemical action, the oxides on the surface of the nozzle (inner wall) will dissolve and decompose, further reducing the blockage of the nozzle. The results are as described in Table 1.

[0073] Table 1

[0074]

[0075]

Embodiment 6-10

[0081] Except that the continuous casting nozzle itself is made of the above-mentioned conductive refractory material, the continuous casting operation is carried out as in Examples 1-5. The results are as described in Examples 1-5 in Table 1.

[0082] Evaluation of the test results shown in Table 1 was carried out in the following manner.

[0083] Comments on nozzle clogging:

[0084] Evaluation is carried out according to the amount of steel passing through each nozzle without clogging and stable pouring.

[0085] Excellent: the amount of steel passing through is more than 500 tons, no blockage occurs,

[0086] Good: The amount of steel passing through is more than 400 tons, and no blockage occurs.

[0087] Possible: the amount of steel passing through is more than 300 tons, no blockage occurs,

[0088] Inferior: The effect of anti-blocking is not obvious, and the amount of steel passed cannot reach 300 tons.

[0089] Evaluation on the anti-corrosion performance of nozzle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com