Electrophoresis waste liquid purification device

A purification device and waste liquid technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sewage treatment, etc., can solve the problems of high cost of transshipment, limited amount of transshipment, excessive volume, etc., to achieve Reduce the effect of long-term use, speed up, and speed up liquid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

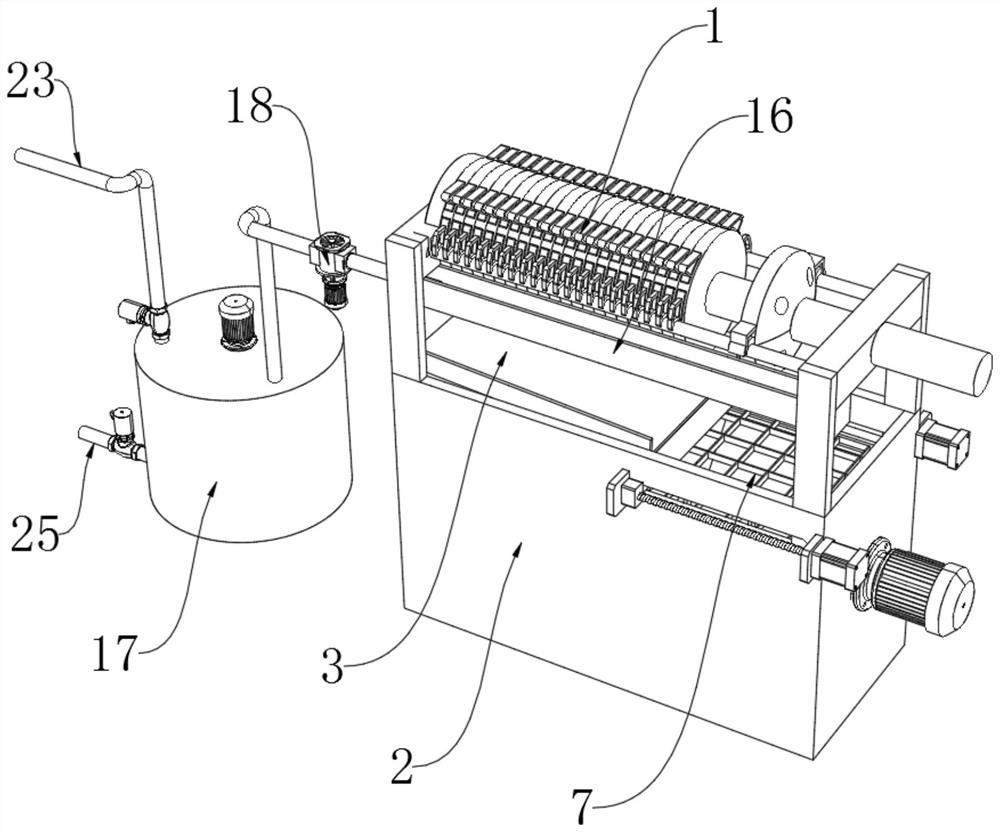

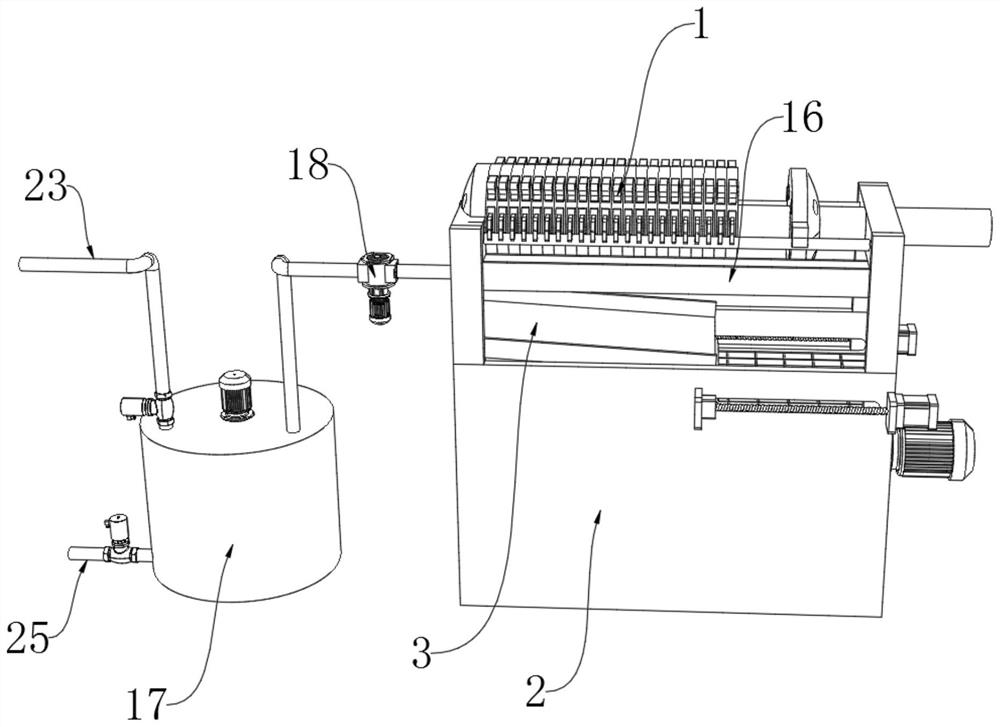

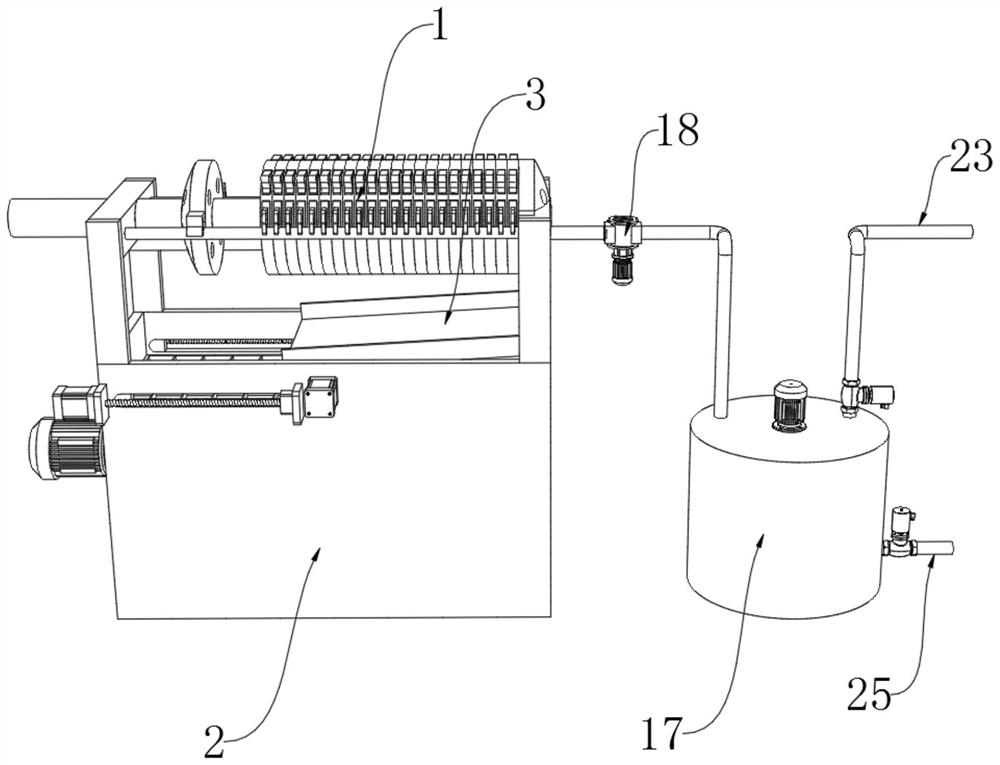

[0039] see Figure 1-Figure 8 , an electrophoresis waste liquid purification device, comprising a filter press 1, a solid processing mechanism and a liquid processing mechanism, the lower end of the filter press 1 is provided with a protective shell 2, and the filter press 1 is fixed to the protective shell 2 through a pillar;

[0040] The filter press 1 is used for solid-liquid separation of waste liquid;

[0041] The solid processing mechanism is used to conduct, cut and transport the mud cake separated by the filter press 1;

[0042] The solid processing mechanism includes a conduction component, a cutting component and a conveying component;

[0043] The conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com