Method of producing amorphous silicon nanoparticles

A nanoparticle and amorphous silicon technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of not being able to obtain highly dispersed quantum dots soluble in solvents and only obtaining nanoparticle composition, and achieve large Effects of application flexibility and range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Method of preparing silicon particles without surfactant coating.

[0016] (1) Use deionized water as the solution.

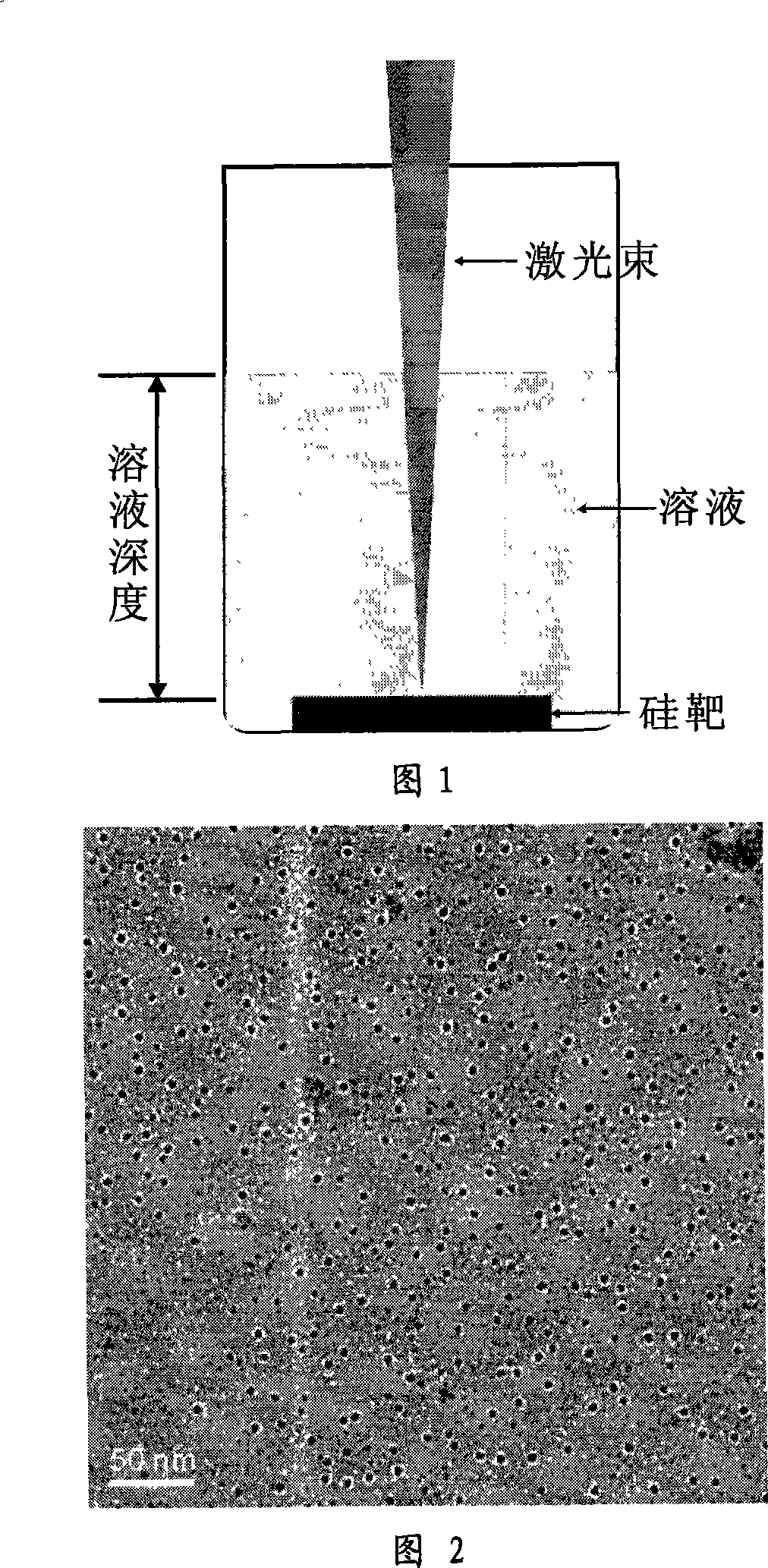

[0017] (2) Place the silicon target in a beaker filled with deionized water, and then irradiate the silicon target with a strong enough KrF excimer laser beam (as shown in Figure 1). During the irradiation, the beaker is placed on a motorized platform that moves horizontally, so that the laser beam scans on the target; at the same time, the silicon target must be completely immersed in the solution to a depth of 1 mm, but not more than 5 mm; the laser beam Focusing through the lens, the focus size is usually 4-10mm 2 , the energy density of the laser is limited to 1×108 -2 ×10 8 W / cm 2 Between; if you want to obtain a high-concentration nanoparticle solution, you can increase the irradiation time and increase the laser energy.

[0018] (3) Take out the silicon target, and the solution contains the prepared amorphous silicon quantum dots, ...

Embodiment 2

[0020] Example 2: Method for preparing surfactant-coated silicon quantum dots. The basic method is the same as that in Example 1, except that a cetyltrimethylammonium bromide solution with a concentration range of 1.0-5.0mmol / L is prepared for use in subsequent steps.

[0021] In order to keep the quantum dots for a long time without agglomeration, it is necessary to use a surfactant solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com