Focusing leveling measuring system

A measurement system, focusing and leveling technology, applied in the field of measurement systems, can solve problems such as poor measurement stability, complex system, measurement error, etc., and achieve the effects of improving measurement accuracy, repeatability and stability, and improving resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

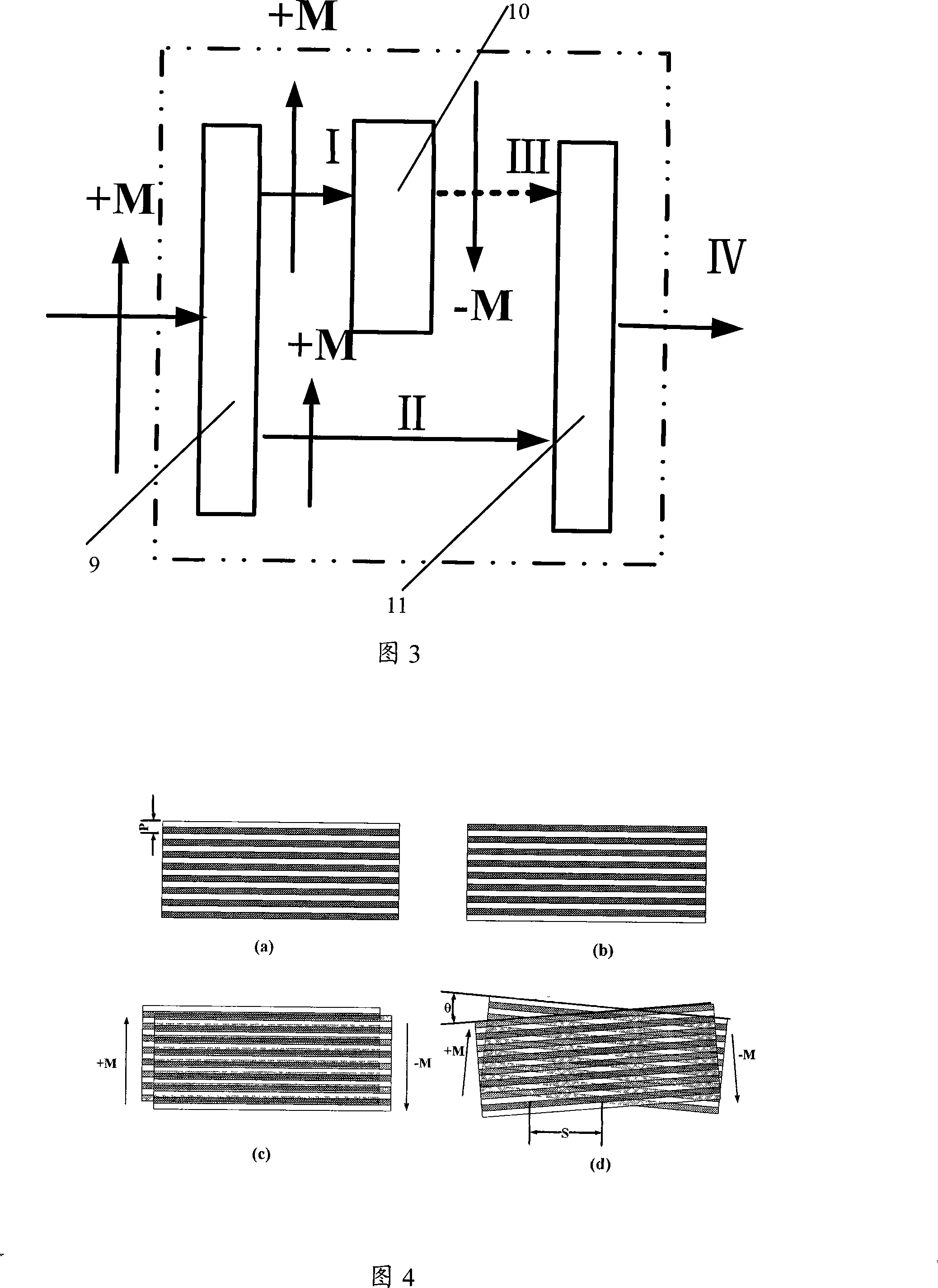

[0027] figure 2 The light emitted by the middle light source module 1 is shaped by the light beam illumination optical module 2 and then irradiated onto the object grating 3; the object grating 3 is imaged by the first imaging module 4 onto the measured silicon wafer (here generally refers to all measured objects) 6 , forming a measurement spot on the upper surface of the silicon wafer 6 . The first imaging module 4 and the second imaging module 8 are imaging systems that are telecentric at least on one side of the silicon wafer 6 . And here the first offset flat plate 5 and the second offset flat plate 7 are mainly used to adjust the measurement zero point of the focusing and leveling measurement system, the first offset flat plate 5 and the second offset flat plate 7 are adjusting At this time, it should be ensured that it can rotate relatively, and the adjustment amount is the same. The detection spot on the upper surface of the silicon wafer 6 is imaged by the second im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com